The introduction of laser engravers has enabled the engraving of almost any material with custom designs. Almost everyone nowadays owns a piece of jewelry or some decorative item that has been laser-engraved. Polishing of rings and other jewelry items is common practice, but the question now is – will laser engraving wear off, and how long does the laser engraving last?

Laser engraving makes indelible marks on the item through the production of a lot of energy targeted at a very small area. This focused energy leaves a permanent mark by melting, heating, vaporizing, or burning the top layer of the material. However, the permanence of laser engraving depends on the material used, the depth of the engraving, what the engraved item is used for, and how often the items are polished.

In other words, it is possible to have one laser-engraved item that lasts a lifetime while another loses the engraved patterns after a couple of years. Let us look at the factors that influence the longevity of laser engravings.

Table of Contents

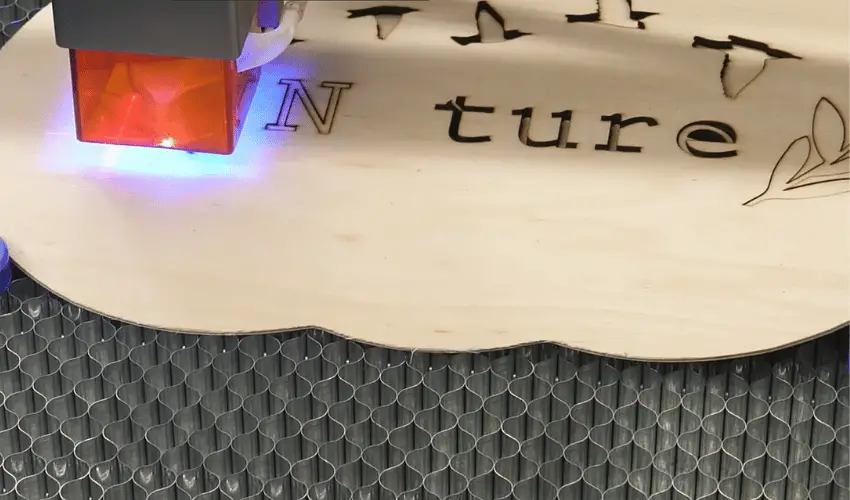

How Laser Engraving Works

Laser engraving uses a concentrated laser beam to physically remove material from a surface, leaving behind a recessed mark. Unlike printing or coating, engraving does not sit on top of the material—it’s cut into it.

This is why laser engraving is considered permanent: the mark becomes part of the material itself.

Factors that determine if laser engraving will wear off with normal use

The material used

Laser engraving can be done on different kinds of materials, and the material used will obviously have a significant impact on the longevity of the engravings. For instance, engravings on gold and other softer metals will wear off faster than on tougher metals like tungsten.

Even if you make deep cuts into the material in a bid to make it more durable, the engravings cannot outlast the material itself. It is okay to use softer metals for jewelry and other accessories, but if the item will be subjected to lots of friction, then it is best to go with tougher metals.

The depth of the engraving

The deeper the engraving, the more durable it will be. However, how deep the laser engraving goes varies based on the material used and the customization needs of a customer. For instance, if you use acrylic, the laser engravings can go to a depth of 0.25mm. Wood engravings can go deeper, like say 0.5mm deep. Going too deep into the material can handle will damage it.

That said, some materials like wood can handle deeper engravings but specialized hardware might be required for that. When buying a laser engraver the manufacturer will have recommended settings and guidelines on how deep you should go on different materials.

What the engraved item is used for

If your engraved item is exposed to lots of friction, it will wear off quicker than if it weren’t as much exposed to friction. For instance, an engraving on the inner part of the ring will not wear off, irrespective of the type of metal used.

The only way for the engravings on the inside to wear off easily is if your finger was rougher and tougher than the metal used to make your ring. Since that is unheard of, engravings on the inside of a ring will last as long as the ring does. But if you were to wear the ring as a pendant on your necklace, the engravings could wear off over the years due to the friction between the chain and the ring.

Related Post: A Complete Guide On Learning How To Engrave Jewelry

Cleaning and polishing

Polishing and cleaning of jewelry and other engraved items can also affect the longevity of the engravings. There are two important tips for cleaning and polishing without causing too much damage to your engravings.

Firstly, do not polish jewelry items too frequently. Only polish and clean your items when it is really necessary rather than doing it as a pastime activity. Secondly, do not use an abrasive polish. The reason why jewelers do a great job of polishing their client’s rings without damaging the engravings is that they only use nonabrasive polish.

How Long Does Laser Engraving Last?

The longevity of laser engraving largely depends on the material being engraved and the conditions it is exposed to over time. Here’s a closer look at how different materials and factors influence the lifespan of laser-engraved items:

Metals

Stainless Steel and Aluminum: Laser engraving on metals like stainless steel and aluminum is exceptionally durable. These materials are often used in harsh environments, including industrial and outdoor settings. The engraving typically lasts the lifetime of the product, resisting wear and corrosion.

Coated Metals: Metals with surface coatings, such as anodized aluminum, also hold up well. The laser removes the coating to expose the metal beneath, and the engraving lasts as long as the coating remains intact. If the coating wears away or is damaged, the engraving may be affected.

Plastics

Acrylic and Polycarbonate: Laser engraving on plastics can be very durable, especially on materials like acrylic and polycarbonate. The depth and clarity of the engraving ensure it remains legible and intact for many years, provided the plastic itself does not degrade significantly.

Surface Treatments: Some plastics are surface-treated to improve durability. The engraving will last as long as the treatment remains effective.

Wood

Hardwoods: Engravings on hardwoods such as oak or maple are quite durable. These woods are less prone to damage and can maintain the engraving for many years, especially if they are well-maintained and protected from excessive moisture or direct sunlight.

Softwoods and Veneers: Softer woods and veneers may show wear and tear more quickly. Engravings can fade or become less distinct over time if the wood is subject to frequent handling or environmental stress.

Glass

Standard and Tempered Glass: Laser engraving on glass is usually permanent. The process creates fine microfractures on the surface that do not easily wear away. However, engraved glass can be more susceptible to scratches, which might affect the visibility of the engraving over time.

Environmental Factors

Several environmental factors can impact the longevity of laser engraving:

- UV Exposure: Prolonged exposure to sunlight can cause materials to degrade. For example, plastics may become brittle and discolored, potentially affecting the visibility of the engraving.

- Humidity and Temperature Fluctuations: Extreme changes in humidity and temperature can cause materials like wood and some plastics to warp or crack, which might compromise the integrity of the engraving.

- Physical Wear and Tear: Items subjected to frequent handling, abrasion, or mechanical stress may show signs of wear more quickly. Metal engravings are generally more resistant to this type of damage compared to other materials.

Maintenance and Care

Proper maintenance can significantly extend the life of laser engravings. Here are some general tips:

- Regular Cleaning: Clean engraved items regularly to prevent the buildup of dirt and grime, which can obscure the engraving.

- Protective Coatings: Applying a clear protective coating can help preserve the engraving on materials like wood and metal.

- Avoiding Harsh Chemicals: Use mild cleaning agents to avoid damaging the material and the engraving.

Also Read: When To Stain Wood for Laser Engraving? Complete Guide!

Mistakes to avoid to prevent laser engraving from wearing off

As we have seen, laser-engraved items can last a lifetime if done the right way and if the items are handled properly. Additionally, there are some mistakes that you can make which will impact the quality and longevity of your engraved items. The following are some common mistakes in laser engraving and how best to avoid them.

Inadequate Surface Preparation When Engraving Metals

Proper surface preparation ensures that the laser can interact with the metal surface as intended, producing clean, crisp, and durable engravings. Without adequate preparation, contaminants and irregularities can interfere with the laser’s performance, resulting in flawed engravings.

Common Mistakes in Surface Preparation

- Failing to Clean the Surface

- Dirt and Debris: Dust, dirt, and debris on the metal surface can obstruct the laser beam, leading to uneven engravings. Always clean the metal thoroughly with a suitable cleaner to remove any particulate matter.

- Oils and Grease: Residual oils and grease from handling or previous processes can cause the laser to produce inconsistent marks. Use a degreaser or alcohol-based cleaner to eliminate any greasy residues.

- Ignoring Oxidation and Corrosion

- Rust and Oxidation: Metals like iron and steel can oxidize, forming rust that interferes with engraving. Ensure any rust or oxidation is removed using appropriate methods, like sanding or chemical treatments, before engraving.

- Surface Coatings: Some metals might have protective coatings or paint that need to be stripped off if they’re not part of the final design. Use chemical strippers or mechanical methods to remove these layers carefully.

- Uneven or Rough Surfaces

- Surface Irregularities: An uneven or rough surface can cause the laser to engrave inconsistently. Sand or polish the metal to create a smooth, uniform surface that the laser can interact with evenly.

- Burrs and Sharp Edges: Metal burrs and sharp edges from previous machining processes can affect the engraving quality. Deburr and smooth out these imperfections before starting the laser engraving.

- Incorrect Surface Treatments

- Inappropriate Coatings: Some surface treatments, like certain coatings or platings, might not interact well with the laser. Ensure the coating is either compatible with laser engraving or remove it if necessary.

- Surface Hardening: Some metals undergo hardening processes that make them difficult to engrave. Ensure the laser settings are adjusted accordingly, or consider pre-treating the surface to soften it slightly.

Using the wrong acrylic

If you use the wrong acrylic, you will not get the characteristic of frosty white engraving. What most beginners do not realize is that there are actually two types of acrylics that should never be used interchangeably.

Cast Acrylic is a derivative of liquid acrylic. It is cast by pouring molten acrylic into a mold. This is the best type of acrylic to use for plaques, signs, and other related products because it easily achieves the frosty white engraving acrylic effect.

The second type of Acrylic is extruded acrylic. This acrylic usually comes in sheet form. Unlike cast acrylic, machines make the sheets, so it doesn’t go through a mold. As a result, it can easily be mass-produced and is, therefore, less expensive. When laser-engraved, this acrylic will cut very smoothly and yield a flame-polished edge. Extruded acrylic is not a good choice for laser engraving, but you can use it for laser cutting.

Cast acrylic is more durable and that is another reason why it’s good for plaques and signs. Choosing the right acrylic to use therefore depends on what kind of finish you want to have and what purpose your finish product will serve.

The Acrylic Materials We Recommend

SimbaLux Acrylic Sheet

3mm, 1/8″, Plastic Plexi Glass Board with Protective Paper is available in different sizes and quantity combinations.

Opaque Glossy Acrylic

3mm, 1/8″, Opaque Glossy Cast Acrylic. Colors: 14 Color Options Size: 12″ x 12″ Quantity: 3 Pcs

Glow in the Dark Acrylic

3mm, 1/8″ Pale Green Glow in the Dark Cast Acrylic Sheet. Quantity: 3pcs, Size: 12″ x 12″

Using the same settings for different woods

Wood is the most user-friendly material for laser engraving because it not only works well for laser cutting but laser engraving. However, some people make the rookie mistake of assuming that all types of wood can be engraved using the same laser engraver settings. Just like when engraving any other material, use a stronger laser when engraving thicker wood and a less powerful laser when engraving lighter wood.

Different types of wood have different grain densities. For instance, Oaks and other types of hardwoods have large veins, while maple and other types of softwoods have smaller veins. This is why softwoods produce a more uniform appearance as opposed to hardwoods. It is, therefore, a good idea to stick to softwoods when laser engraving. Common softwoods for engraving include maple, walnut, alder, and cherry.

Best Wood Options For Laser Engraving

Explore the top wood options for laser engraving below to deliver clean and precise results.

Image | Product | Details | Price |

|---|---|---|---|

| Baltic Birch Plywood | Thickness: 3mm (1/8″) Sizes: 6 x 6″, 6 x 12″, 8 x 8″, 10 x 10″, 12 x 8″, 12 x 9″ Quantity: 8 / 12 / 16 / 25 / 45 / 50 / 100 | |

| Basswood Sheets | Thickness: 3mm (1/8″) Size: 12 x 12″ Sheets Quantity: 18 / 30 / 42 |

Not cleaning your laser engraving machine

A clean laser engraver will produce better results than one that is not cleaned regularly. Start by going through the user manual of your laser engraver because the manufacturers typically include important maintenance tips and instructions. As a rule of thumb, check the laser optics regularly and clean any debris as the need arises.

Obviously, how regularly you clean the optics will be determined by how often you use the laser. The optics should be bright and shiny when clean, so if you inspect them and find that they are cloudy or have debris on them, it is a telltale sign that it’s time to clean them. A clean laser engraver will help you to achieve better laser engravings, which will, in turn, be more durable over time.

Laser Engraving vs Other Marking Methods

Marking Method | Durability | Wear Resistance | Ideal For |

|---|---|---|---|

Laser Engraving | Permanent | Excellent | Metals, wood, plastics, ceramics |

Laser Etching | Long-lasting but shallower | Good | Branding, barcodes, logos |

Printing (ink/paint) | Temporary | Poor | Short-term labels, designs |

Stickers/Decals | Temporary | Poor | Packaging, decoration |

Can Laser Engraving Wear Off?

- Yes, but only if the engraved surface itself is worn down. For example, constant sanding of wood or polishing of metal can reduce the depth of the mark.

- On durable metals like stainless steel, engraving will outlast the product itself.

How to Make Laser Engravings Last Longer

- Choose the right material: Metals and ceramics offer maximum longevity.

- Engrave deeper: Especially important for high-use items like tools, jewelry, or signage.

- Apply protective coatings: Wood and some plastics benefit from sealants.

- Avoid harsh cleaners: Use mild soaps instead of abrasives or strong chemicals.

Frequently Asked Questions

Does laser engraving fade over time?

No, laser engraving does not fade like ink or paint. Since the process removes material and creates a permanent mark, it only wears down if the surface itself erodes, is polished, or experiences heavy abrasion.

Is laser engraving permanent on metal?

Yes. Laser engraving on metals such as stainless steel, aluminum, or brass is highly permanent. In most cases, the engraving will last as long as the metal object itself, even in industrial or outdoor environments.

Can laser engraving wear off wood?

Laser engraving on wood is durable, but it can wear off if the surface is sanded, refinished, or exposed to excessive moisture and sunlight. Applying a clear sealant or finish helps preserve the engraved design.

Does laser engraving rub off on glass or ceramics?

No. Engravings on glass and ceramics are permanent because the laser physically alters the surface. However, if the item chips, cracks, or breaks, the engraving may be affected along with the material.

How can I make my laser engraving last longer?

To maximize longevity:

Choose durable materials like metal, glass, or ceramics.

Deeper engravings rather than shallow surface etching.

Use protective coatings on wood or plastic.

Avoid abrasive cleaning methods that may wear down the surface.

Final Thoughts

So in summary, the longevity of any laser engraving will be hugely determined by the materials used, the technique used, and the kind of exposure the item gets during the day-to-day usage. Also, avoiding the common mistakes highlighted above can help improve the quality and longevity of the laser engravings.

The durability of laser engraving is generally excellent, often outlasting the material it is applied to. For most applications, laser engravings are designed to last a lifetime, especially when proper care and maintenance are observed. Whether used for industrial purposes, decorative items, or personal keepsakes, laser engraving provides a long-lasting and resilient method for marking and personalization.

For best results, always match the best materials with the best laser engraving machines. For more on this, check out our guide on the best laser engravers for small business.