Choosing the best laser engraver can feel overwhelming. With so many technologies, power levels, features, and price points, it’s easy to get lost—especially if you’re a beginner or planning to upgrade your workshop.

This comprehensive guide walks you through everything you need to know about selecting the right laser engraver based on your materials, budget, project types, and business goals. Whether you’re crafting at home or running a production shop, this guide will help you make a confident and profitable choice.

Table of Contents

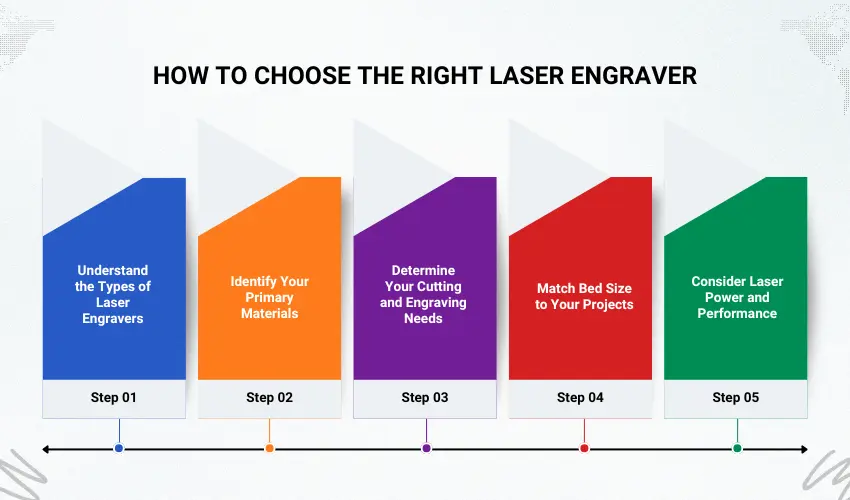

1. Understand the Types of Laser Engravers

Before choosing a machine, you must understand the three main laser technologies—each designed for different materials.

A. Diode Lasers (Blue Laser – 455 nm)

Best for: Wood, leather, acrylic (dark), coated metals, rubber, paper

Not suitable for: Clear acrylic, clear glass, most bare metals

Pros:

- Affordable

- Portable and beginner-friendly

- Safe and easy to use

- Great for hobbyists and small businesses

Cons:

- Lower cutting power

- Limited compatibility with transparent materials

Popular examples:

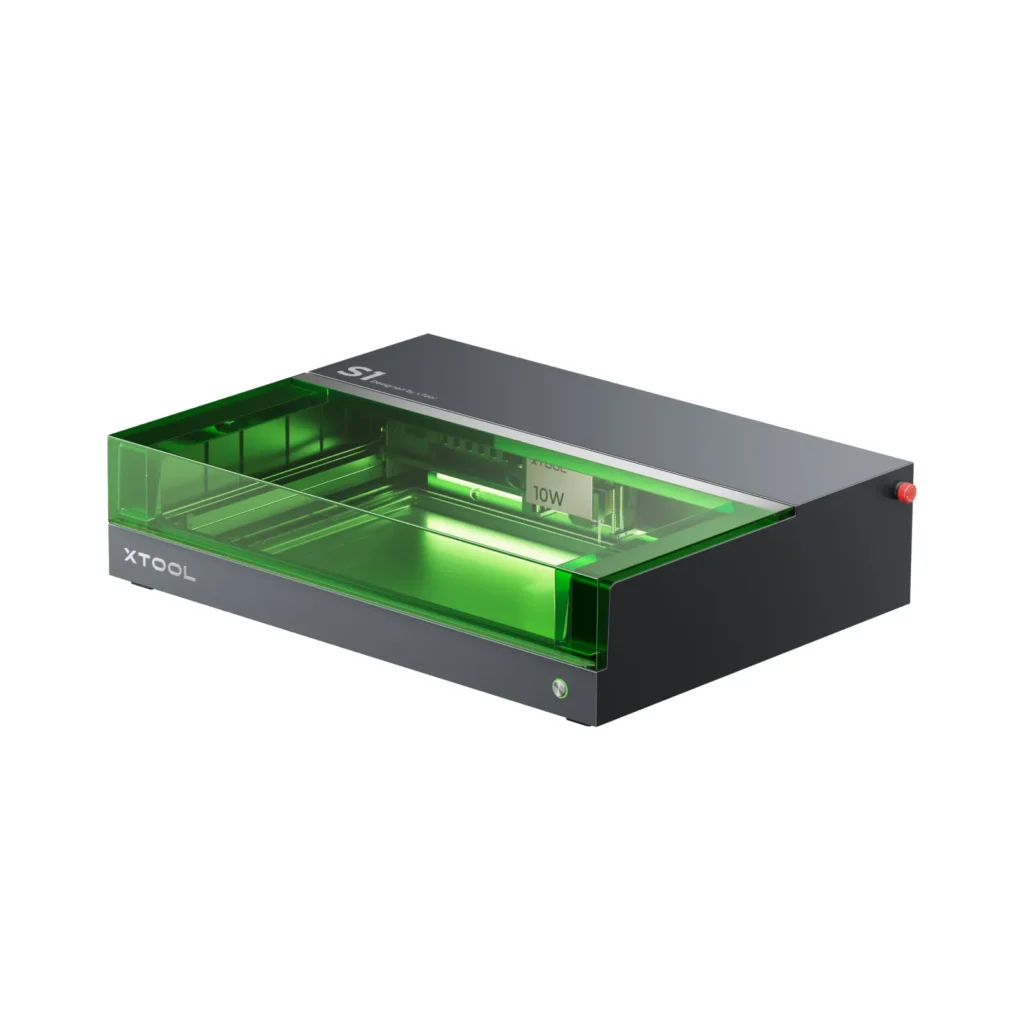

xTool S1, xTool M1 Ultra

B. CO₂ Lasers (10,600 nm)

Best for: Wood, acrylic (all colors), leather, glass (surface), rubber, fabric

Not suitable for: Metal engraving without additives

Pros:

- Fast and powerful

- Cuts thick materials

- High-quality on acrylic

- Ideal for production volume

Cons:

- Larger footprint

- Requires water cooling

- More maintenance than diode/fiber

Popular examples:

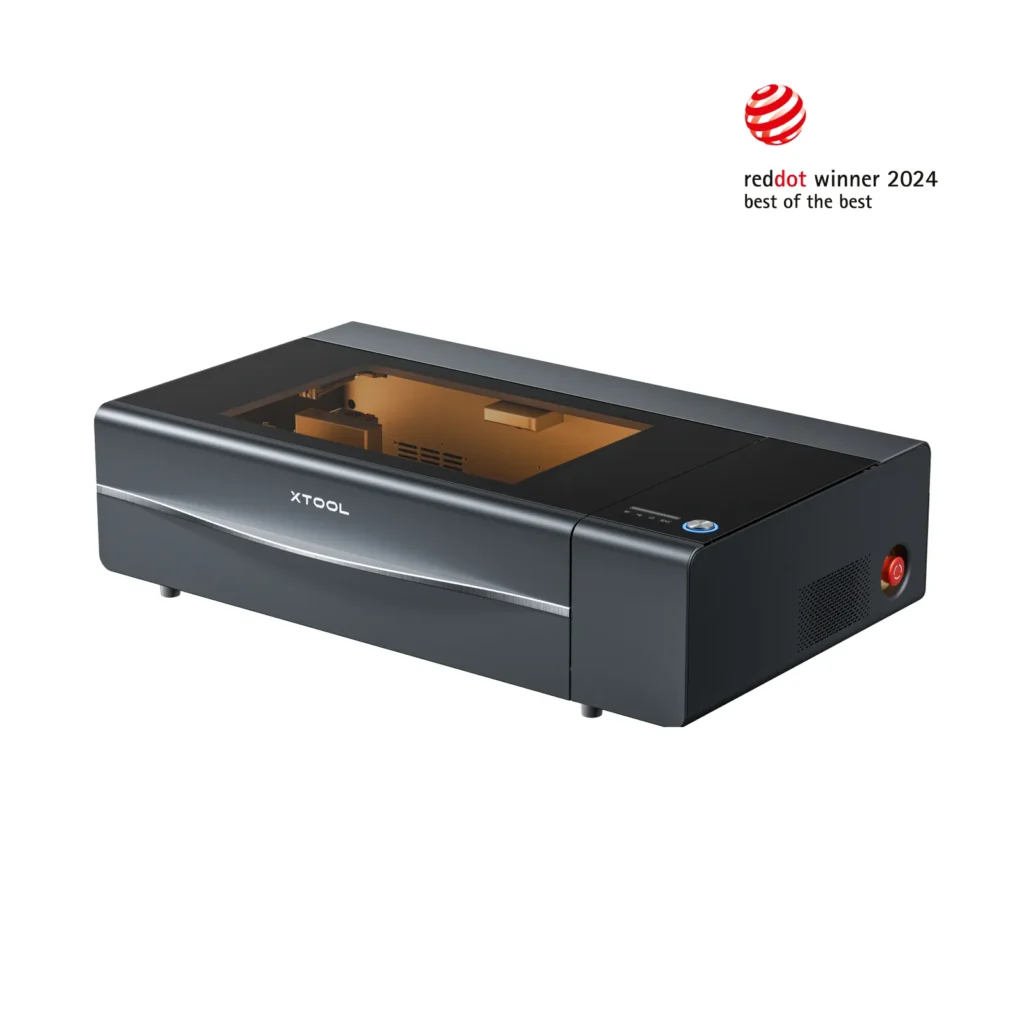

xTool P2S/P3

C. Fiber & IR Lasers (1,064 nm / 1,060–1,100 nm)

Best for: Metal engraving, deep metal marking, jewelry, stainless steel, plastics

Not suitable for: Wood, acrylic cutting, fabric

Pros:

- Ultra-precise metal engraving

- Fast galvo speeds (up to 15,000 mm/s)

- Deep engraving & color marking on metal

Cons:

- Cannot cut most common maker materials

- Higher cost for beginners

Popular examples:

xTool F1 Ultra, xTool F2 Ultra, typical 20–100W galvo fiber machines

D. UV Lasers (355 nm – Ultraviolet)

Best for: Glass, crystal, stone, acrylic, plastics, fine marking

Not suitable for: Thick cutting of wood or large materials

Pros:

- Best for glass surface & internal 3D engraving

- Micro-precision marking

- Works on sensitive materials

Cons:

- More expensive

- Not ideal as a “general-purpose” laser

Popular examples:

xTool F2 Ultra UV

2. Identify Your Primary Materials

Your material list determines your laser type. Use the quick matrix below.

Material Compatibility Matrix

Material | Diode | CO₂ | Fiber/IR | UV |

|---|---|---|---|---|

Wood | Excellent | Excellent | No | Limited |

Acrylic (clear) | No | Excellent | No | Excellent detail |

Acrylic (colored) | Good | Excellent | No | Good |

Leather | Very Good | Very Good | No | No |

Glass (surface) | No | Good | No | Excellent |

Glass (internal) | No | No | No | Best |

Metal marking | With spray | With spray | Excellent | Good for fine detail |

Plastics | Good | Good | Industrial marking | Micro-precision |

Bottom line:

- If you engrave glass, choose UV.

- If you engrave metal, choose fiber/IR.

- If you cut wood or acrylic, choose CO₂.

- If you’re on a budget or starting a hobby, choose diode.

3. Determine Your Cutting and Engraving Needs

Laser machines vary dramatically in power, workflow, and precision.

A. Engraving Only

Choose: Fiber, UV, or small diode

Great for:

- Jewelry

- Personalization

- Gifts

- Logos

B. Engraving + Cutting

Choose: CO₂ or high-power diode (20–40W)

Great for:

- Signs

- Acrylic crafts

- Small business products

- Leather goods

- Wood decor

C. Production and Business Use

Choose:

- CO₂ laser (55–130W) for cutting

- Fiber galvo for metal marking

- UV for glass engraving

Add-ons worth investing in:

- Rotary for tumblers / rings

- Automatic conveyor for long board feeding

- High-powered air assist

- Camera alignment system

4. Match Bed Size to Your Projects

Bigger isn’t always necessary—but too small limits you.

Small Work Area (200 × 200 mm or below)

- Desktop diode lasers

- Fiber/UV galvos

Best for: Names, badges, jewelry, ornaments

Medium Work Area (300 × 300 mm)

- Prosumer diode lasers

Best for: Etsy shops, small businesses

Large / Enclosed CO₂ (400 × 300 mm – 600 × 400 mm)

Best for: Cutting large sheets, production, batch work

Pass-through Compatible Machines

- xTool S1

- xTool P2S

Best for: Signs, long wood boards, furniture pieces

5. Consider Laser Power and Performance

The wattage you need depends on what you plan to cut.

Diode Laser Power Guide

Diode Power | Cuts | Best For |

|---|---|---|

10W | Thin wood, paper | Hobby use |

20W | 3–8 mm wood | Small business |

40W | Thick wood, fast cutting | Production-level |

CO₂ Laser Power Guide

CO₂ Power | Cuts | Best For |

|---|---|---|

40W | Thin wood, light hobby | Basic crafting |

55W–60W | 8–15 mm wood | Small businesses |

80–130W | 15–30 mm wood | Industrial production |

Fiber Laser Power Guide

Fiber Power | Engraving Depth | Best For |

|---|---|---|

20W | Logos, text | Jewelry, tags |

30–50W | Medium-depth | Tools, knives |

60–100W | Deep marking, color | Industrial shops |

6. Safety, Build Quality & Reliability

A safe machine is non-negotiable. Look for:

- Fully enclosed housing (Class 1)

- Laser shield windows

- Emergency stop button

- Fire detection & suppression (optional but ideal)

- Air assist to prevent flare-ups

- Fume extraction or filtering

Also consider:

- Metal frame vs. plastic

- Quiet, stable motion system

- High-quality linear rails

- Upgradable accessories

7. Software Compatibility & Ease of Use

Good software improves workflow significantly.

Choose a laser that works with:

- LightBurn (industry standard)

- Manufacturer software like xTool Creative Space or xTool Studio

Look for features like:

- Camera alignment

- Auto-focus

- Material presets

- Batch processing

- 3D object preview

8. Budget vs. Value: What Should You Spend?

Here’s a price breakdown by use case.

Beginner / Hobby

$200–$1,000

- Diode lasers, small bed size

- Great for learning and small crafts

Prosumer / Small Business

$1,000–$3,500

- High-power diode

- Entry-level CO₂

- Compact fiber engravers

Professional / Production

$3,500–$10,000+

- CO₂ (80–130W)

- Advanced fiber and UV galvo systems

- Automation accessories

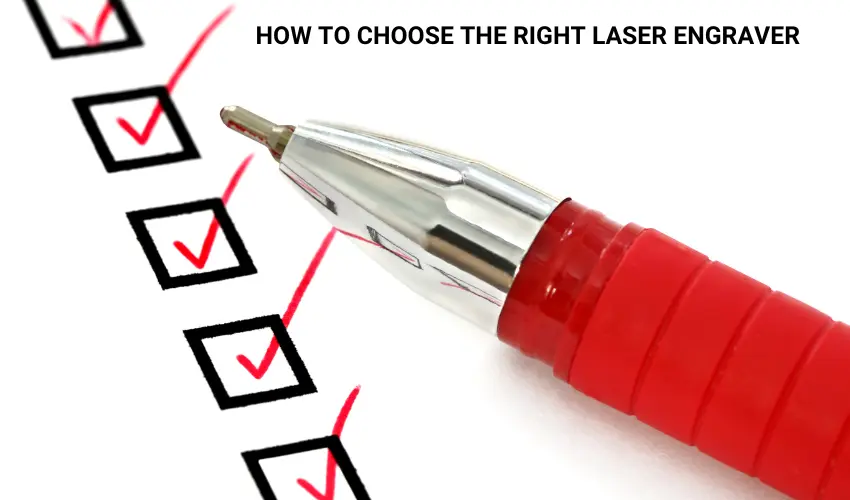

Final Decision Checklist

Use this quick checklist to ensure you choose the perfect machine:

What materials will you engrave or cut?

Do you need surface engraving, cutting, or interior 3D engraving?

What bed size fits your largest project?

What power level supports your cutting goals?

Do you need rotary engraving (tumblers, rings)?

Should the system be enclosed for safety?

Does it support camera alignment or autofocus?

Is the machine compatible with LightBurn?

Does the manufacturer offer strong support and replacement parts?

If you can answer these questions, you’re ready to buy the perfect laser engraver with confidence.

The Laser Engraver We Recommend

xTool has become one of the most trusted brands in the laser engraving and cutting industry—and for good reason. Whether you’re a hobbyist, small business owner, or professional engraver, xTool delivers a combination of performance, safety, reliability, and innovation that stands out from competitors.

Below are the top reasons we recommend xTool laser machines.

Industry-Leading Safety Features (Best in Class)

xTool is known for building machines that prioritize safe operation without sacrificing power.

- Fully enclosed Class 1 models

- Fire Safety Kits with automatic flame detection

- Built-in air assist and ventilation options

- Emergency stop and key switches on pro units

- Protective covers that block harmful laser wavelengths

This makes xTool machines ideal for homes, classrooms, studios, and small businesses.

A Machine for Every Purpose and Budget

One of xTool’s biggest strengths is its wide product lineup, covering all major laser technologies:

• Diode Lasers (xTool S1, M1 Ultra)

Great for beginners, crafters, hobbyists, and small shops.

• CO₂ Lasers (xTool P2S)

High-power cutting and engraving for wood, acrylic, rubber, leather, and batch production.

• Fiber/MOPA Lasers (xTool F1 Ultra, F2 Ultra)

Professional metal engraving, color marking, and industrial-quality results.

• UV Lasers (xTool F2 Ultra UV)

Best choice for glass engraving, crystal 3D inner engraving, and fine marking on plastics.

No matter what materials you engrave or cut, there is an xTool machine built specifically for you.

Exceptional Precision & Engraving Quality

xTool invests heavily in laser technology, offering features like:

- High-speed galvo systems (up to 15,000 mm/s)

- Ultra-fine spot sizes as small as 0.02–0.03 mm

- Dual 48MP cameras for perfect design alignment

- Advanced autofocus + LiDAR ranging

- MOPA fiber lasers for full-color metal engraving

Whether you’re engraving jewelry, customizing gifts, or running a production shop, xTool delivers crisp detail and consistent results.

Fast Workflow + Smart Software (Beginner Friendly)

xTool Studio is one of the easiest laser applications available:

- Drag-and-drop design interface

- AI-powered auto-focus and auto-measure

- Accurate camera preview

- Compatible with LightBurn (most models)

- Batch processing & automated conveyor options

- 3D model engraving support (F2 Ultra UV)

This makes xTool machines perfect for both new users and experienced professionals.

Strong Accessory Ecosystem

xTool supports many official add-ons that expand what your laser can do:

- RA3 / RA2 Pro rotary attachments

- Automatic Conveyor Feeders

- Inline Fans & Air Purifiers

- Riser bases for taller objects

- Slat tables and honeycomb panels

- Pedal switches for production workflow

This ecosystem gives you room to scale, whether you run a home shop or a multi-machine business.

Reliable Support, Tutorials & Community

xTool offers:

- Live chat + responsive customer support

- Large user community groups

- Detailed beginner guides

- Free project templates

- Step-by-step video tutorials

- Strong warranty coverage

This is a huge advantage for people starting a laser business or learning for the first time.

Excellent Price-to-Performance Value

Compared to other brands (Glowforge, OMTech, Thunder, Aeon), xTool machines often offer:

- More features

- Better cameras

- Higher precision

- Faster speeds

- More accessories

- Lower total cost

xTool strikes a rare balance between affordability and professional-level capability.

Perfect for Small Businesses & Personalization Services

xTool is one of the most popular choices for small business owners because it excels in:

- Fast production speed

- Repeatable precision

- High material compatibility

- Safe indoor operation

- Compact footprint

- Affordable upgrade path

Whether you’re engraving tumblers, jewelry, leather goods, cutting boards, awards, acrylic signs, or crystal gifts, xTool machines offer the best ROI.

Bottom Line: Why We Recommend xTool

xTool continues to set the standard in the consumer and prosumer laser market by offering:

- Powerful machines for every skill level

- Industry-leading safety and precision

- Excellent accessories and software

- Best price-to-performance value

- Reliable support and active community

Whether you’re a hobbyist, educator, or business owner, xTool provides the perfect combination of quality, practicality, and performance.

Laser Engraver Comparison Chart

Feature / Model | xTool S1 (10W/ 20W / 40W Diode) | xTool P2S (55W CO₂) | xTool F1 Ultra (20W Fiber + 20W Diode) | xTool F2 Ultra (60W MOPA Fiber + 40W Diode) | xTool F2 Ultra UV (5W UV 355 nm) |

|---|---|---|---|---|---|

Laser Type | Diode 455 nm | CO₂ 10,600 nm | 20W Fiber + 20W Diode | 60W MOPA Fiber + 40W Diode | 5W UV (355 ± 5 nm) |

Primary Use | Wood, leather, colored acrylic | Wood, acrylic (all), leather, rubber | Metal engraving + all-purpose engraving | Industrial metal marking + high-power diode cutting | Glass engraving (surface & 3D inner), plastics, fine marking |

Engraving Area | 40W: 19.6″ × 12.5″ (498 mm × 319 mm) 10W/20W: 19.6″ × 13″ (498 mm × 330 mm) | 23.6″ × 12″ (600 mm × 305 mm) | 8.6″ × 8.6″ (220 mm × 220 mm) With conveyor: 8.6″ × 19.6″ (220 mm × 500 mm) | 8.6 × 8.6 (220 mm × 220 mm) 8.6 × 19.6 (220 mm × 500 mm) with conveyor | Inner Engraving: 2.8″ × 2.8″ (70 mm × 70 mm) Surface Engraving: 7.9″ × 7.9″ (200 mm × 200 mm) Surface Engraving with Conveyor: 7.9″ × 19.7″ (200 mm × 500 mm) |

Max Speed | 40W/20W: 600 mm/s 10W: 400 mm/s | 600 mm/s (X-axis Acceleration 6400 mm/s²) | 10,000mm/s | 15,000 mm/s | 15,000 mm/s |

Cutting Ability | Best-in-class for diode cutting | Excellent for thick wood/acrylic | Limited (diode only) | Strong (40W diode) | Limited (UV is not for cutting except thin materials) |

Metal Engraving | With spray only | With spray only | Excellent (fiber) | Industrial-grade color/deep metal engraving | Fine marking on metal but not deep engraving |

Glass Engraving | Surface only (low quality) | Good surface engraving | No | No | Best for 2D/3D inner and surface engraving |

Acrylic Engraving | Only dark acrylic | Best for all acrylic | Great detail on coated acrylic | Great detail / limited cutting | Excellent detail, no melting |

Camera System | Yes (automatic) | Dual 16MP | Yes | Yes | Dual 48MP Cameras |

Auto-focus | Yes | Yes | Yes | Yes | Advanced autofocus + LiDAR |

Rotary Support | RA2 Pro | RA2 Pro, RA3 | RA2 Pro | RA2 Pro, RA3 | RA2 Pro, RA3 |

Pass-through | Yes | Yes | No | No | No |

Best For | Beginners, hobbyists, small shops | Small businesses needing high-volume cutting | Jewelry, knives, tags, metal crafts | Industrial shops, deep engraving, metal color marking | Glass engraving, crystal gifts, fine plastic/metal marking |

Safety Rating | Class 1 | Class 1 | Class 1 | Class 1 / 4 | Class 1 / 4 |

Price Range | $999–$2,919 Check Latest Price Here | $3,269–$6,259 Check Latest Price Here | ~$3,269 Check Latest Price Here | ~$4,649 Check Latest Price Here | ~$4,249 Check Latest Price Here |

Which Machine Should You Choose? (Quick Recommendations)

For Wood & Acrylic Cutting → xTool P2S or S1 40W

- P2S = best for thick acrylic

- S1 = budget-friendly + fast + enclosed

For Metal Engraving → xTool F1 Ultra or F2 Ultra

- F1 Ultra = fast, compact, affordable

- F2 Ultra = industrial-grade with color marking & MOPA precision

For Glass Engraving → xTool F2 Ultra UV

- Best for 3D internal crystal engraving

- Clean, non-burned surface engraving

- Works on plastics, silicone, and delicate materials

For All-purpose Small Business → S1 40W or P2S

- Both support large projects + pass-through

- CO₂ for acrylic, diode for affordability

For Professional Custom Shops → F2 Ultra + P2S combo

- Metal + acrylic + wood + business volume

- Fastest workflow with complementary strengths

Frequently Asked Questions

What type of laser engraver should I choose—diode, CO₂, fiber, or UV?

This depends entirely on the materials you plan to work with:

Diode Laser (xTool S1, M1 Ultra):

Best for wood, leather, acrylic (dark), paper, rubber, and coated metals. Great for beginners and budget-friendly use.

CO₂ Laser (xTool P2S):

Ideal for thick cutting and high-production work. Works extremely well with wood, acrylic, rubber, leather, fabric, and food. Not ideal for bare metals.

Fiber/MOPA Laser (xTool F1 Ultra, F2 Ultra 60W):

Best for metal engraving, color marking, tools, jewelry, and industrial applications.

UV Laser (xTool F2 Ultra UV):

Best for glass engraving, crystal inner engraving, clear acrylic, plastics, PCB, and ultra-fine details.

If you’re unsure, match the laser to your most frequently used material.

How much laser power do I actually need?

Laser power affects speed and cutting ability:

5–20W diode: Best for engraving and light cutting.

20–40W diode: Strong cutting performance for wood and acrylic.

40W+ CO₂: Best for thick cutting (10–20mm materials) and high-speed batch work.

20–60W fiber/MOPA: Required for deep metal engraving and industrial work.

5W UV: Best for precision detail, glass, and plastics—not for thick cutting.

Choose power based on your required speed and maximum material thickness.

Do I need a machine with a camera or autofocus?

You don’t need them, but they make life MUCH easier:

Cameras allow accurate drag-and-place positioning.

Autofocus ensures perfect laser clarity with no manual measuring.

LiDAR systems (in xTool P2S/F2 Ultra) give advanced auto-measurement for curved or uneven objects.

If you engrave one-off items, custom gifts, or irregular shapes, these features greatly reduce errors and setup time.

What size working area should I choose?

This depends on the size of your projects:

Small portable systems (F1 Ultra, F2 Ultra): Best for small items like jewelry, tags, tumblers, metal cards, small parts.

Medium work area (xTool S1): Perfect for crafting, leatherwork, signs, décor, and small business products.

Large enclosed area (xTool P2S): Best for batch production, large signs, shelving, furniture components, and big acrylic pieces.

If you plan to scale your business, always choose the largest workspace you can afford.

What safety features should I look for in a laser engraver?

Safety is essential—especially when used indoors. Look for:

Fully enclosed housing (Class 1 preferred)

Laser-blocking viewing window

Emergency stop and key switch

Fire detection / extinguishing compatibility

Air assist + smoke filtration options

UL/CE-certified power supplies

Proper ventilation or inline fan systems

xTool machines are popular because they incorporate many of these safety features out-of-the-box.

Conclusion

Choosing the right laser engraver doesn’t have to be complicated. Start with your materials, choose the right laser type, match the power to your workload, and ensure the machine has the features and safety you need.

Whether you’re engraving jewelry, cutting wood signs, marking metal tools, or engraving glass art, there’s a perfect machine for your needs—one that will help you produce better work, save time, and grow your business.