When it comes to laser cutting and engraving, the materials you use can make or break your results—and that includes the tape you apply to your workpieces.

Two of the most commonly used tapes in the laser crafting world are laser masking tape and transfer tape. But they’re not the same, and using the wrong one can lead to charring, poor detail, or adhesive residue.

Table of Contents

In this guide, we’ll break down the key differences between masking and transfer tape, when to use each, and how they can impact the quality of your laser projects.

What Is Masking Tape?

Laser masking tape is a low-adhesive tape designed to protect the surface of your material during engraving or cutting. It helps:

- Prevent scorch marks and smoke stains

- Minimize cleanup

- Shield parts of the material from the laser beam

Most laser masking tapes are made to withstand moderate heat and can be applied to wood, acrylic, leather, and more. They’re usually paper-based and come in rolls of various widths.

Best for:

- Masking wood or acrylic before engraving

- Preventing discoloration during laser cutting

- Simple, broad-area protection

What Is Transfer Tape?

Laser Transfer tape is used to transfer vinyl or other adhesive materials, but in laser crafting, it’s valued for its ability to tightly bind to detailed cuts and engraved designs.

Unlike masking tape, transfer tape has:

- Stronger adhesive

- Higher heat resistance

- Greater clarity for alignment and precision

There are two main types: paper-based and clear film transfer tapes. Laser users usually prefer the paper version for masking purposes due to its breathability and low-glare surface.

Best for:

- Intricate designs with fine detail

- Multi-pass engraving or high-power settings

- Cleaner masking of edges and corners

Masking Tape vs Transfer Tape: Key Differences For Laser Projects

Feature | Laser Masking Tape | Transfer Tape |

|---|---|---|

Purpose | Surface protection during engraving | Precision application and masking |

Adhesion | Medium, easy-peel | Stronger, better for fine detail |

Heat Resistance | Moderate | Higher, suitable for powerful lasers |

Cost | Lower, more budget-friendly | Slightly higher due to specialized design |

Application | Ideal for broad areas | Ideal for sharp, intricate lines |

Residue Risk | Low if removed properly | Very low when used correctly |

When to Use Masking Tape For Laser Projects

Use masking tape when:

- You’re engraving unfinished wood, bamboo, or acrylic

- Your design is simple and doesn’t need fine edge masking

- You want to reduce smoke stains or burn marks

- You need a cost-effective solution for bulk projects

Pro tip: Choose a laser-safe masking tape like TapeManBlue, which won’t leave residue and can withstand moderate heat

Recommended Masking Tape For Laser Projects

TapeManBlue Wide Painters Tape 6 inch x 60 yds

The TapeManBlue Wide Painters Tape (6 inch x 60 yds) is an excellent all-purpose masking solution, especially well-suited for laser cutting, 3D printing, and painting applications. Made in the USA, this extra-wide blue tape delivers strong adhesion while still removing cleanly, leaving no sticky residue or surface damage—even after 21 days.

As a laser masking tape, it protects materials during engraving and helps achieve crisp, clean results. It also shines as a 3D printer bed tape, offering reliable adhesion for flawless prints. Its wide format is a time-saver too, eliminating the need to overlap narrower strips when covering larger areas.

Thanks to its curl-resistant durability, easy application, and multi-surface compatibility, TapeManBlue is a go-to option for crafters, makers, and professionals who need consistent performance without hassle. Whether you’re engraving wood, prepping for a detailed stencil, or printing with precision, this tape gets the job done efficiently and cleanly.

When to Use Transfer Tape for Laser Projects

Use transfer tape when:

- You’re working with detailed graphics, logos, or text

- You’re using multiple passes or high-speed engraving

- You want maximum adhesion and no shifting during laser runs

Pro tip: Apply transfer tape using a squeegee or roller to ensure full adhesion without air bubbles

Recommended Transfer Tape For Laser Projects

TapeManBlue 12″ x 300′ Roll of Paper Transfer Tape

The TapeManBlue 12″ x 300′ Roll of Paper Transfer Tape is a standout option for laser engraving and cutting, delivering professional-grade performance with a user-friendly design. Made in the USA, this premium 4-mil paper tape features a layflat adhesive that ensures smooth, bubble-free application for Cricut, Silhouette, and laser cutting projects.

Perfect for transferring vinyl decals, letters, or intricate graphics, this medium-high tack tape grips securely during the transfer process while still offering clean, residue-free removal. It’s especially ideal for laser crafters who need precise alignment and clean finishes on wood, acrylic, or painted surfaces.

The generous 12″ x 300′ roll size adds excellent value, making it great for both professionals and hobbyists handling bulk projects. If you want reliable, American-made transfer tape that saves time and enhances quality, TapeManBlue delivers.

Tips for Better Results

No matter which tape you choose, follow these best practices:

- Clean your material before applying tape

- Apply evenly with a roller or squeegee to avoid bubbles

- Trim excess tape neatly with a sharp blade

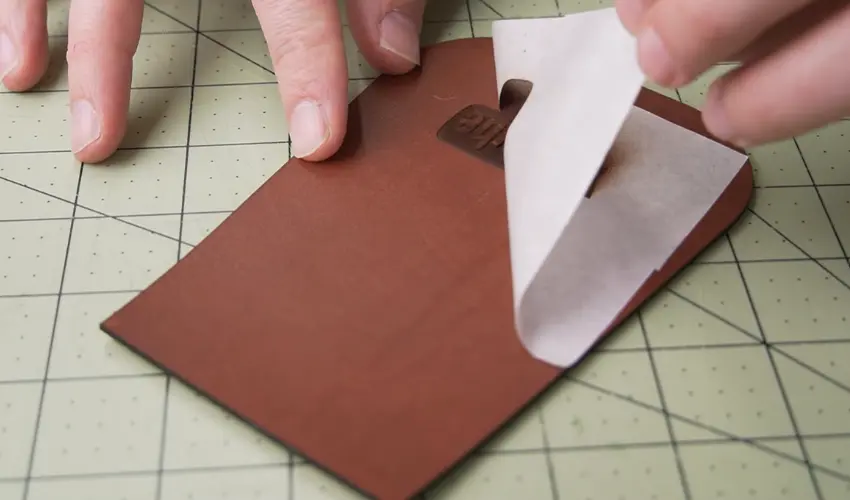

- Peel slowly after engraving to prevent lifting material

- Test on scraps before starting your final project

How to safely remove tape after laser cutting and engraving

1. Removing Tape Safely

After laser engraving, let the material cool completely before removing the masking tape. Heat can make the adhesive stickier and harder to remove. Start by gently lifting one corner using a plastic scraper or your fingernail—be careful not to scratch the surface. Peel the tape back slowly and close to horizontal to prevent tearing or leaving residue.

If any adhesive remains, use a microfiber cloth with rubbing alcohol or a mild adhesive remover to wipe it away. Be gentle—abrasive cleaning can damage the engraving or the material.

2. Cleaning After Tape Removal

Once the tape is off, inspect the surface for any leftover residue. Use a microfiber cloth dampened with isopropyl alcohol or a gentle adhesive remover to clean stubborn spots. Rub in small circular motions to lift residue without harming the material.

After cleaning, wipe the area with a damp cloth (just water) to remove any remaining chemicals, then dry thoroughly with a soft, lint-free cloth to leave a clean, polished surface.

3. Troubleshooting Tape Removal Issues

If the tape tears easily or leaves sticky residue, the problem may be poor-quality tape or removing it while the surface is still warm. Always use laser-safe masking tape designed for clean removal under heat.

For stubborn residue:

- Try a stronger adhesive remover, but test it on a hidden area first.

- Use a hair dryer on low heat to soften tough adhesive before peeling.

- For delicate engravings, remove tape slowly and carefully, especially around detailed or thin lines.

By using the right tape and removal techniques, you’ll keep your projects looking sharp and professional without damage.

Frequently Asked Questions

What’s the main difference between masking tape and transfer tape for laser projects?

Masking tape is typically used to protect surfaces from smoke stains, charring, or residue during laser cutting or engraving. It’s great for general coverage and budget-friendly jobs. Transfer tape, on the other hand, is specifically designed to lift and apply detailed vinyl or laser-cut designs without stretching or distortion. It’s ideal for intricate work requiring precision.

Can I use masking tape for detailed laser engraving work?

Masking tape works best for basic designs or surface protection. However, for intricate or fine-detail projects, it may not provide the cleanest results due to lower adhesive quality and lack of heat resistance. Transfer tape is better suited for this because it holds detailed designs firmly and removes cleanly without tearing.

Is transfer tape more heat-resistant than masking tape during laser cutting?

Yes. Transfer tape is generally more heat-resistant and less likely to curl or degrade under the intense heat of a laser beam. Masking tape, unless it’s high-temp rated, can scorch or leave residue, especially during longer or more powerful engraving jobs.

Which is more cost-effective for bulk or beginner laser projects?

Masking tape is usually more affordable and works well for bulk production of simple designs or for protecting large surface areas. It’s a great option for beginners or basic masking needs. Transfer tape, while more expensive, is worth the investment for high-quality, detailed, or client-ready projects.

Conclusion: Which Tape Should You Use?

- Use masking tape for simple designs, wood engraving, and affordable coverage.

- Use transfer tape for sharp details, multi-layer projects, or when high-precision is essential.

Still unsure? Keep both in your laser toolkit. The right tape at the right time can be the difference between a good project and a great one.