One of the advantages of owning a laser engraver is the wide array of materials that can be engraved. Traditionally, laser engravers were too expensive for the man in the street but the introduction of inexpensive ones has now made it possible for anyone to set up a laser engraving business. All you have to do is buy a good laser engraver, choose the best material and you are good to go!

But which are the best materials for laser engraving? A laser engraver can be used to engrave, laser-cut, and mark several materials including rubber, leather, plastics, textiles, wood, and metals.

However, if you are using a fiber laser engraver, then you may want to avoid working with organic materials like wood and leather because even though they are not transparent to the human eye, they appear transparent to the 1062nm wavelength of the fiber laser beam. It is, therefore, a good idea to ask the manufacturer of your laser for the list of permitted and disallowed materials before you start using it.

Table of Contents

Some of the commonly laser engraved materials

- Wood

- Glass

- Acrylic

- Metal

- Paper and Cardboard

- Fabric

- Leather

- Marble and Granite

Our Recommended Materials and Supplies:

Product | Check Price |

Baltic Birch Plywood, 3 mm 1/8 x 10 x 10 Inch Craft Wood | |

3mm MDF Sheets – 12″ x 12″ Sheets (20 Pieces) | |

18 Pack Wood Sheets 12″x8″x1/16″ for Crafts | |

Blank Wooden Chipboard Sheets for Crafts and Signs (9×12 Inches, 12 Pack) | |

SimbaLux Acrylic Sheet Clear Cast Plexiglass 12” x 12” Square Panel 1/8” Thick (3mm) Pack of 2 | |

12″ x 24″ – 1/8″ Clear Extruded Acrylic Plexiglass Sheet | |

120 Pieces Metal Business Cards Anodized 0.2mm Thick Multi-Color Aluminum Blanks Name Card 3.4 x 2.1 Inch | |

uxcell Blank Metal Card 88x53x0.4mm Brushed 201 Stainless Steel Plate | |

Greenstar TransferRite Ultra 582U Medium Tack Transfer Tape 12″ x 10 Yard Roll – Prevent Burn Marks On Wood | |

BLARYETI Felt Tipped Squeegee to apply transfer tape |

Let’s look at some of the best materials for laser engraving in more detail.

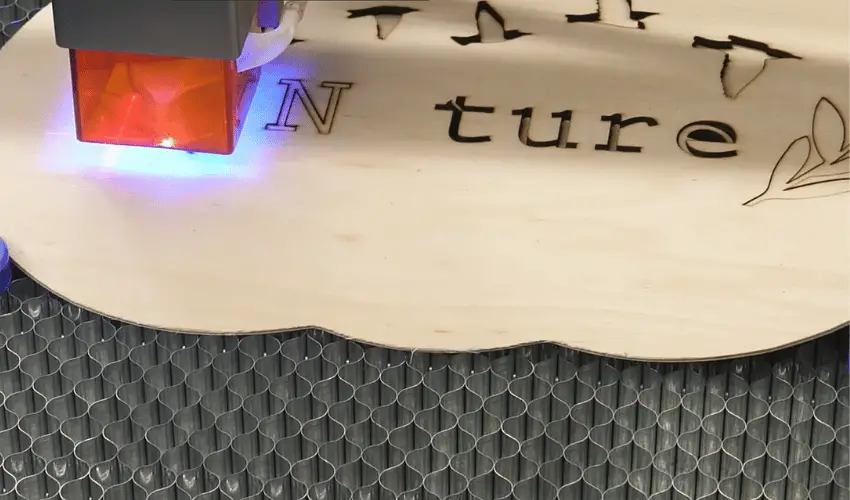

Laser Engraving On Wood

Wood is a popular material for engraving because you can use almost any type of wood and you can also use several laser cutting and laser engraving techniques to achieve different results. Here are some of the commonly engraved types of wood.

- Natural wood, real wood

- Solid wood, solid timber

- Plywood

- Chipboard

- Cork

- MDF

- HDF

- Veneers

- Precious woods

- Multiplex

Understanding the Basics:

1. Types of Wood Suitable for Laser Engraving:

- Hardwoods: Maple, cherry, walnut, and oak are popular choices for their density and fine grain.

- Softwoods: Pine, cedar, and birch engrave well, offering a contrasting appearance.

2. Preparing Wood for Laser Engraving:

- Surface Cleaning: Ensure the wood surface is clean and free from debris to achieve a precise and clean engraving.

3. Choosing the Right Settings:

- Power and Speed: Adjust the laser power and engraving speed based on the type of wood. Experiment with settings on a small test piece.

Advanced Techniques:

1. Photo Engraving on Wood:

- Use grayscale images for realistic photo engravings.

- Adjust the laser settings to achieve varying shades and depths.

2. Vector Graphic Designs:

- Create vector graphics for sharp and detailed designs.

- Experiment with line thickness and spacing for different effects.

3. Adding Texture:

- Vary the laser power to create textured effects on the wood.

- Mimic wood grain patterns or add a distressed look for artistic appeal.

4. Color Filling:

- Apply paint or specialized wood stains to engraved areas for vibrant and contrasting colors.

- Wipe off excess color to highlight engraved details.

Best Practices:

1. Test Engravings:

- Always conduct test engravings on scrap wood to fine-tune settings and ensure the desired outcome.

2. Ventilation and Safety:

- Ensure proper ventilation, especially when engraving treated or painted wood.

- Use appropriate safety gear, including protective eyewear and gloves.

Also Read: Top 5 Laser Engraver Exhaust Fan Options: Best Quality!

3. Focus and Alignment:

- Regularly check and calibrate the laser focus and alignment to maintain precision in engravings.

4. Choosing the Right Wood Thickness:

- Adjust the laser focus based on the thickness of the wood to achieve optimal results.

5. Post-Processing:

- Sand the engraved surface gently to remove any residue or imperfections.

- Apply a clear finish to enhance the appearance and protect the engraving.

Troubleshooting Tips:

1. Incomplete Engravings:

- Check and adjust laser power and speed settings.

- Ensure the wood surface is flat and level.

2. Burnt Edges:

- Reduce laser power or increase engraving speed.

- Consider masking the wood surface to protect edges.

3. Uneven Engravings:

- Check for variations in wood thickness.

- Calibrate the laser focus and alignment.

Laser Engraving On Glass

Laser engraving can be done on almost all kinds of glass items to produce stunning effects. Mugs, vases, wine bottles, and wine glasses are just some of the examples of items that can be engraved. Most established wineries and distillers use laser engraving to etch their logos on their bottles.

If you are a collector of wines, you might make your bottles unique by adding custom engravings with your laser marker. The advantage of laser engraving glass is that the laser will not cut the glass deeply. On the contrary, it will leave a frosted look. You must, however, be meticulous when laser engraving glass because you might end up with a rough surface thanks to the chipping that might be caused by the laser.

Understanding the Basics:

1. Types of Glass Suitable for Laser Engraving:

- Annealed Glass: Standard glass suitable for engraving.

- Tempered Glass: Requires specialized lasers and may produce subtle results.

- Coated Glass: Coatings can impact engraving quality; test different types.

2. Preparing Glass for Laser Engraving:

- Cleaning: Ensure the glass is clean and free from smudges or oils.

- Masking: Applying masking tape helps protect the glass surface and minimizes chipping.

3. Choosing the Right Settings:

- Power and Speed: Experiment with laser power and engraving speed for optimal results.

- DPI (Dots Per Inch): Higher DPI settings result in finer details but may require slower engraving.

Advanced Techniques:

1. 3D Engraving on Glass:

- Achieve a three-dimensional effect by varying the laser power and focus.

- Experiment with depth to create captivating designs.

2. Color Filling:

- Apply specialized glass paints or coatings to engraved areas.

- Wipe off excess color for a clean and vibrant appearance.

3. Photo Engraving on Glass:

- Use grayscale images for realistic photo engravings.

- Adjust laser settings to capture varying shades and depths.

Best Practices:

1. Test Engravings:

- Conduct test engravings on scrap glass to fine-tune settings and visualize outcomes.

2. Ventilation and Safety:

- Ensure proper ventilation when engraving coated or painted glass.

- Use protective eyewear and follow safety guidelines.

3. Focus and Alignment:

- Regularly check and calibrate the laser focus and alignment for precise engravings.

4. Masking Techniques:

- Experiment with different masking materials, such as transfer tape or adhesive paper.

- Remove masking carefully after engraving to reveal the design.

5. Post-Processing:

- Clean the engraved glass surface with a gentle glass cleaner.

- Consider applying a clear finish for added protection and a polished look.

Troubleshooting Tips:

1. Inconsistent Engravings:

- Check for variations in glass thickness.

- Ensure the glass surface is flat and level.

2. Chipping or Cracking:

- Use the right type of glass

Crystal glass will not work too well for laser engraving because it has too much lead content. Lead can retain a lot of the heat from the laser and this makes it impossible to achieve a uniform engraving. As a rule of thumb, test the type of glass you will be using before you engrave on the real item.

- Know the difference between flat and round glass

Flat glass has a consistent hardness, unlike curved glass which typically has hard and soft spots. If you are engraving a bottle, mug, or some other curved glass, go with the medium speed with a high power. It will help compensate for any inconsistencies.

- Masking

Masking is the process of placing a paper towel or a wet newspaper on the glass before laser engraving it. The idea is to help dissipate some heat. If you decide to mask, make sure your paper towel is spread evenly on the glass or you might just end up with a lot of chipping. If you are not able to make the paper truly flat, it is best to avoid masking altogether.

Some of the laser engravers come with software that makes laser engraving on glass just a breeze. That’s because they have an intuitive editor that you can use to see exactly where your engraving will go on your glass item before you start engraving.

3. Burn Marks:

- Adjust laser power and speed settings.

- Experiment with multiple passes for controlled engraving.

Laser Engraving On Acrylic

Acrylic sheets, sometimes known as polymethyl methacrylate (PMMA) are durable and lightweight and can serve as great alternatives to glass. PMMA can be manufactured in two ways – cast or extruded.

These two types of acrylic respond differently to laser engraving.

Understanding Acrylic:

1. Types of Acrylic:

- Cast Acrylic: Preferred for laser engraving due to its clarity and smooth surface.

- Extruded Acrylic: May produce less consistent results; test settings before engraving.

2. Preparing Acrylic for Engraving:

- Cleaning: Ensure the acrylic is free from dust and fingerprints.

- Masking: Apply masking tape to protect the surface and reduce scorching.

3. Choosing the Right Laser Settings:

- Power and Speed: Experiment with laser power and engraving speed for optimal results.

- DPI (Dots Per Inch): Higher DPI settings produce finer details but may require slower engraving.

Advanced Techniques:

1. 3D Engraving on Acrylic:

- Vary the laser power to achieve a three-dimensional effect.

- Experiment with depth to add visual interest to your engravings.

2. Color Filling:

- Apply acrylic paint or specialized fillers to engraved areas.

- Wipe off excess color for a clean and vibrant appearance.

3. Edge-Lit Designs:

- Engrave intricate patterns or text on acrylic sheets for edge-lit effects.

- Use LED lights to illuminate the engraved areas for a captivating look.

Best Practices:

1. Test Engravings:

- Conduct test engravings on scrap acrylic to fine-tune settings.

- Check for any residue left by masking tape and adjust settings accordingly.

2. Ventilation and Safety:

- Ensure proper ventilation, especially when engraving colored or coated acrylic.

- Use protective eyewear and follow safety guidelines.

3. Focus and Alignment:

- Regularly check and calibrate the laser focus and alignment for precise engravings.

4. Masking Techniques:

- Experiment with different masking materials to find the one that works best for you.

- Remove masking carefully after engraving to reveal the design.

5. Post-Processing:

- Clean the engraved acrylic with a mild cleaner to remove any residue.

- Consider adding a clear finish for added protection and a glossy finish.

Troubleshooting Tips:

1. Burn Marks:

- Adjust laser power and speed settings to prevent scorching.

- Ensure proper ventilation to remove any fumes generated during engraving.

2. Inconsistent Engravings:

- Check for variations in acrylic thickness.

- Ensure the acrylic sheet is flat and securely positioned.

3. Scorching on Masking Tape:

- Adjust laser power or try a different masking tape brand.

- Ensure the masking tape is applied smoothly to avoid residue.

Laser Engraving On Metal

Almost all types of metals can be laser engraved or laser marked but the following are some of the most commonly engraved and marked ones:

- Steel

- Copper

- Iron

- Stainless steel

- Aluminum

- Brass

- Silver

- Gold

- Paladium

- Titanium

- Platinum

- Carbides

- Coated metals

Metal is one the most commonly used materials in the world and laser engraving, as well as laser cutting, come in handy in all manner of scenarios.

Some examples include the creation of art pieces, alteration of aircraft wings for better aerodynamics, the manufacture of automotive parts, engraving of parts, etc. We can, therefore, categorize laser engraving of metals into two functional categories; industrial laser engraving and promotional laser engraving.

Understanding Metal Engraving:

1. Types of Metals:

- Stainless Steel: Ideal for laser engraving, provides high-contrast markings.

- Aluminum: Reacts well to laser engraving, producing clean and precise results.

- Brass and Copper: Offer a classic and elegant appearance when engraved.

2. Preparing Metal Surfaces:

- Cleaning: Ensure the metal surface is free from oils, dirt, and debris.

- Coating: Apply a coating or marking compound to enhance contrast.

3. Choosing the Right Laser Settings:

- Power and Speed: Adjust laser power and engraving speed based on metal type.

- Frequency: Experiment with different frequencies for varied engraving effects.

Advanced Techniques:

1. Deep Metal Engraving:

- Vary laser power and speed for deeper engravings.

- Consider multiple passes for intricate and pronounced designs.

2. Color Marking on Metal:

- Utilize specialized marking compounds for adding color to engravings.

- Experiment with different compounds for varied color results.

3. Annealing on Stainless Steel:

- Use lower power settings to create annealed (oxidized) markings on stainless steel.

- Achieve a permanent and corrosion-resistant engraving.

Best Practices:

1. Test Engravings:

- Conduct test engravings on a sample piece to determine optimal settings.

- Adjust focus and alignment for precise results.

2. Ventilation and Safety:

- Adequate ventilation is crucial, especially when engraving metals that may produce fumes.

- Wear appropriate personal protective equipment, including eyewear.

3. Surface Coating:

- Experiment with different coatings to enhance engraving visibility.

- Remove excess coating carefully after engraving.

4. Metal Marking Compounds:

- Choose marking compounds suitable for the type of metal you’re engraving.

- Follow manufacturer guidelines for application and removal.

5. Post-Processing:

- Clean engraved metal surfaces with a mild cleaner to remove residues.

- Consider applying a protective clear coat for long-lasting results.

Troubleshooting Tips:

1. Incomplete Engravings:

- Ensure adequate power settings for the metal type.

- Check for inconsistencies in metal thickness.

2. Fading or Discoloration:

- Adjust power and speed settings to avoid excessive heat.

- Experiment with different coatings to prevent discoloration.

3. Inconsistent Focus:

- Regularly check and calibrate the laser focus for consistent engravings.

- Ensure the metal surface is flat and properly aligned.

Laser Engraving On Paper and Cardboard

From decorated greeting cards to custom book covers, the possibilities of making breathtaking laser engraved cardboard and paper items are endless. Some of the types of paper that would be ideal for laser engraving include:

- Art paper

- Fine paper

- Cardboard

- Corrugated cardboard

- Handmade paper

One main advantage of paper and cardboard is that they are inexpensive as opposed to the other materials that can be laser engraved. Additionally, the applications for paper are endless.

Understanding Paper and Cardboard Engraving:

1. Types of Paper and Cardboard:

- Cardstock: Thick and sturdy, ideal for invitations and cards.

- Kraft Paper: Natural and rustic, suitable for packaging and labeling.

- Coated Paper: Provides a smooth surface for detailed engravings.

2. Preparing Materials:

- Surface Quality: Ensure the paper or cardboard is flat and free from wrinkles.

- Secure Placement: Use masking tape to secure materials and prevent movement.

3. Choosing the Right Laser Settings:

- Power and Speed: Adjust according to material thickness and desired engraving depth.

- DPI (Dots Per Inch): Higher DPI settings result in finer details but may extend engraving time.

Advanced Techniques:

1. Halftone Engraving:

- Utilize halftone techniques for creating shades and gradients.

- Adjust laser power and speed to control the intensity of engraving.

2. Vector Cutting:

- Combine engraving with vector cutting for intricate designs.

- Experiment with different cutting depths for varied effects.

3. Paper Coating for Contrast:

- Apply a thin coat of masking or engraving compound for enhanced visibility.

- Test different coatings for optimal contrast without affecting paper quality.

Best Practices:

1. Test Engravings:

- Conduct test engravings on a small section to determine ideal settings.

- Adjust focus and alignment for precise and consistent results.

2. Ventilation and Safety:

- Ensure adequate ventilation, especially when working with coated papers.

- Wear appropriate personal protective equipment, including eyewear.

3. Secure Placement:

- Use a honeycomb cutting grid or pins to secure paper or cardboard.

- Prevent material movement during the engraving process.

4. Material Thickness:

- Adjust focus and settings based on the thickness of the paper or cardboard.

- Experiment with different materials to find the ideal settings for each.

Troubleshooting Tips:

1. Burnt Edges:

- Reduce power settings or increase engraving speed to minimize burning.

- Experiment with different coatings to protect paper edges.

2. Inconsistent Engravings:

- Check for variations in material thickness across the surface.

- Ensure the laser is properly calibrated for even focus.

3. Excessive Charring:

- Experiment with lower power settings for light engravings.

- Consider using materials with lower lignin content to reduce charring.

Laser Engraving On Fabric

Both natural and synthetic fabrics are good candidates for laser engraving. Cotton and microfiber are however the most commonly laser engraved fabrics. Microfiber is made from polyamides (nylon), polyesters, and a mixture of polyamide and polyester.

Microfibers are very durable and this is precisely why they are commonly used for laser engraving. 100% cotton that has a tight weave can also result in breathtaking engraving. If you decided to engrave on cotton, make sure you go for fabric that has tightly fitting threads because lose threads will not give a good result.

Other fabrics that are good for laser engraving include denim, felt, twill and fleece. These fabrics are durable enough to withstand the heat of the laser. You can use them to come up with aesthetically appealing specialty merchandise.

When engraving on fabric, it is best to go with high speed and low power. This gives the laser beam a chance to quickly burn away the top part in order to yield the desired effect. Before you start your engraving, test with a couple of swatches until you have found the perfect settings. This will ensure that you do not burn your fabric when you start laser engraving it.

As a rule of thumb, avoid engraving any fabric that has loose knitting, like terry cloth, because they are not sturdy enough for the process.

Understanding Fabric Engraving:

1. Types of Fabrics:

- Cotton: Known for its natural fibers, cotton is a popular choice for engraving.

- Polyester: Synthetic fabrics like polyester can yield vibrant and durable engravings.

2. Preparing Fabrics:

- Surface Preparation: Ensure the fabric is clean, smooth, and free from wrinkles.

- Material Fixation: Secure the fabric in place using masking tape or specialized fabric holders.

3. Choosing the Right Laser Settings:

- Power and Speed: Adjust according to fabric type, thickness, and desired engraving depth.

- DPI (Dots Per Inch): Higher DPI settings result in finer details but may extend engraving time.

Advanced Techniques:

1. Halftone Engraving:

- Utilize halftone techniques for creating shades and gradients on fabric.

- Adjust laser power and speed to control the intensity of engraving.

2. Vector Cutting:

- Combine engraving with vector cutting for intricate designs on fabric.

- Experiment with different cutting depths for varied effects.

3. Masking for Protection:

- Apply masking tape or special fabric masking materials to protect surrounding areas.

- Remove the masking after engraving to reveal the finished design.

Best Practices:

1. Test Engravings:

- Conduct test engravings on a scrap piece of fabric to determine ideal settings.

- Adjust focus and alignment for precise and consistent results.

2. Ventilation and Safety:

- Ensure proper ventilation, especially when working with synthetic fabrics.

- Wear appropriate personal protective equipment, including eyewear.

3. Fabric Fixation:

- Use specialized fabric holders or frames to keep the material taut and prevent movement.

- Experiment with different fixation methods for optimal results.

4. Material Characteristics:

- Consider the composition of the fabric, as natural and synthetic fibers may react differently to engraving.

- Adjust settings based on the absorbency and heat resistance of the fabric.

Troubleshooting Tips:

1. Burn Marks:

- Reduce power settings or increase engraving speed to minimize burn marks.

- Test different fabrics to find the optimal settings for each.

2. Smoky Residue:

- Use fabric-specific cleaning methods to remove any smoky residue.

- Ensure proper ventilation to minimize residue buildup.

3. Inconsistent Engravings:

- Check for variations in fabric thickness and texture.

- Calibrate the laser for even focus across the entire engraving area.

Laser Engraving On Leather

Customized leather items are always in demand and there is just a no better way of customizing a leather item than laser engraving it. Almost all kinds of leather items can be laser engraved and yes- that includes nubuck and suede. Here is a list of the commonly engraved leather types.

- Suede leather

- Nubuck leather

- Synthetic leather

- Alcantra leather

- Napped leather

- Natural leather

Even the man-made leather, also known as synthetic leather, can be laser engraved. The most important consideration when laser engraving leather is the color. Generally speaking, dark and black leather should be avoided for engraving projects. Engraved patterns will be more visible on lighter leather.

Because of its wide use, there are all manner of leather items that you can engrave. Here are some examples:

- Purses

- Wallets

- Bracelets

- Belts

- Crafts

- Briefcases

- Office products

- Promotional materials

Laser engraving is perfect for leather items because leather is quite tough and it is hard to make aesthetically appealing marks using other tools.

Understanding Leather Engraving:

1. Types of Leather:

- Full-Grain Leather: Known for its durability, full-grain leather engraves beautifully, showcasing natural textures.

- Top-Grain Leather: Slightly processed, top-grain leather provides a smooth surface for detailed engravings.

- Vegetable-Tanned Leather: Ideal for intricate designs, this type of leather develops a rich patina over time.

2. Preparing Leather:

- Surface Cleaning: Ensure the leather surface is clean and free from dust, oils, or residues.

- Masking: Apply masking tape to protect areas not intended for engraving and prevent smoke residue.

3. Choosing the Right Laser Settings:

- Power and Speed: Adjust based on the type and thickness of the leather.

- DPI (Dots Per Inch): Higher DPI settings result in finer details but may increase engraving time.

Advanced Techniques:

1. Image Transfer:

- Utilize specialized software to transfer images or designs onto the leather surface.

- Experiment with different engraving depths for varying effects.

2. Coloring Engravings:

- Apply leather dyes or paints to engraved areas for added contrast and visual appeal.

- Ensure the dye is compatible with the type of leather used.

3. Vector Cutting:

- Combine engraving with vector cutting for creating intricate leather patterns.

- Adjust cutting settings for different leather thicknesses.

Best Practices:

1. Test Engravings:

- Conduct test engravings on a small piece of leather to determine optimal settings.

- Adjust focus and alignment for consistent results across the entire project.

2. Ventilation and Safety:

- Ensure proper ventilation in the workspace to manage smoke produced during engraving.

- Wear protective gear, including safety glasses, when working with lasers.

3. Leather Fixation:

- Use clamps or specialized fixtures to secure the leather in place during engraving.

- Avoid excessive movement to maintain precision.

4. Understanding Leather Characteristics:

- Recognize that different leather types may react differently to the laser.

- Adjust settings based on the absorbency and heat resistance of the specific leather.

Troubleshooting Tips:

1. Burn Marks:

- Reduce power settings or increase engraving speed to minimize burn marks.

- Experiment with different types of leather to find optimal settings.

2. Smoky Residue:

- Use a clean, dry cloth to wipe away any smoky residue after engraving.

- Adequate ventilation helps minimize residue buildup.

3. Inconsistent Engravings:

- Check for variations in leather thickness and texture.

- Calibrate the laser for even focus across the entire engraving area.

Laser Engraving On Marble and Granite

Marble and granite are great materials for engraving photos. This is mainly because granite and marble yield an awesome contrast when engraved. If you use dark-colored marble or granite, you will get a high contrast so there will be no need to add color. The resultant image should be white or dark grey as long as the engraving is done properly.

But how do you know which one to use between marble and granite?

The easiest way to know which one to go with between marble and granite is to start by finding out where the engraved item will be displayed, i.e., will it be a wall hanging in a house or will it be displayed outdoors? If the piece will be placed inside, then you can use either marble or granite.

However, it is best to with granite for any pieces that will be exposed to the elements. That’s because granite is a harder material than marble. To put that into perspective, the Moh scale places marble at a 3 while granite is placed at a 7 in terms of hardness. Granite is close to diamond because the Moh scale gives the diamond a 10.

Understanding Stone Engraving:

1. Types of Stone:

- Marble: Known for its timeless beauty and veined patterns, marble engraving results in contrasting and visually striking designs.

- Granite: Recognized for its durability and speckled appearance, granite offers a robust canvas for detailed engravings.

2. Preparing Stone:

- Surface Cleaning: Ensure the stone surface is clean and free from dust or debris.

- Masking: Apply masking tape or film to protect areas not intended for engraving and reduce residue.

3. Choosing the Right Laser Settings:

- Power and Speed: Adjust based on the hardness and color of the stone.

- DPI (Dots Per Inch): Higher DPI settings result in finer details but may increase engraving time.

Advanced Techniques:

1. Image Conversion:

- Convert images or designs into grayscale for optimal contrast on stone surfaces.

- Experiment with various engraving depths to achieve three-dimensional effects.

2. Adding Color:

- Apply specialized stone paint or infills to engraved areas for enhanced visibility.

- Test compatibility and durability of colorants with the stone type.

3. Depth Variation:

- Utilize variable engraving depths to create textured effects on the stone surface.

- Experiment with shading techniques for realistic and artistic outcomes.

Best Practices:

1. Testing on Sample Pieces:

- Conduct test engravings on small, similar stone pieces to determine optimal settings.

- Account for variations in stone hardness and composition.

2. Ventilation and Safety:

- Ensure proper ventilation to manage dust and potential fumes during the engraving process.

- Wear appropriate safety gear, including respiratory protection, to safeguard against particles.

3. Fixating Stone:

- Secure the stone in place using specialized fixtures or clamps to prevent movement.

- Consider using a rotary attachment for cylindrical or rounded stone surfaces.

4. Understanding Stone Characteristics:

- Recognize that different stones may react uniquely to laser engraving.

- Adjust settings based on the hardness, density, and color of the specific stone.

Troubleshooting Tips:

1. Surface Fractures:

- Reduce power settings or increase engraving speed to minimize the risk of surface fractures.

- Use stones with a smoother, less porous surface for intricate designs.

2. Inconsistent Engravings:

- Check for variations in stone hardness or density.

- Calibrate the laser for even focus across the entire engraving area.

3. Residue Management:

- Wipe away residual dust or debris using a clean, dry cloth after engraving.

- Implement efficient dust extraction systems to maintain a clean work environment.

Related Resources:

Final thoughts

So in summary, there isn’t one best material for laser engraving. The most ideal material will depend on the factors described above. Before you buy your laser engraver, first of all, determine what kind of material you intend to engrave on.

Some materials work best with cutting as opposed to engraving and will, therefore, work better with engravers that have been specially made for that. Other materials are harder than others and will, therefore, require a more powerful laser beam. Once you have settled on your preferred material, you can then purchase a laser engraver that would be most ideal for you.