If you’re in the market for a high-end, production-ready desktop CO₂ laser machine, the xTool P3 makes a serious case. With an 80 W CO₂ laser, a large work area, smart automation, and pro-level safety features, this machine is designed to bridge the gap between hobbyist equipment and industrial production.

In this article, we’ll discuss what the P3 offers, its standout features, what kinds of users will benefit most, its limitations, and whether it’s the right investment for you.

Table of Contents

xTool P3 Key Specifications

Core Specifications

Feature | xTool P3 Specification |

|---|---|

Laser Power | 80W CO₂ Laser Tube |

Wavelength | 10.6 μm (10600 nm) |

Laser Tube Lifespan | ~10,000 hours |

Power Consumption | Max 1400W (100–240V AC) |

Laser Class | Class 1 (Class 4 with Conveyor Feeder) |

Noise Level | ≤ 65 dB (≤ 68 dB with purifier) |

Air Assist | 30 L/min airflow, 200 kPa pressure |

Processing Area | 915 × 458 mm (36 × 18 in) |

Max Work Height | 220 mm (manual) / 180 mm (auto) |

Max Cutting Thickness | 20 mm wood, 25 mm clear acrylic |

Max Speed | 400 mm/s (vector), 1200 mm/s (bitmap) |

Precision | ±0.01 mm |

Machine Weight | 105 kg (device), 152 kg (packaged) |

Compatible Materials

The xTool P3 can cut and engrave a wide variety of materials, including:

- Wood, acrylic, leather, MDF, ABS, paper, and fabric.

- Works with most materials supported by xTool P2/P2S.

Camera & Auto Features

Camera | Function |

|---|---|

Distant-View Camera | Material alignment, live monitoring |

Close-View Camera | Precision positioning |

Upper & Lower Corner Cameras | Real-time flame detection |

Accuracy | Up to 0.2 mm in center area |

The Auto Mode handles auto-focusing, material recognition, and height measurement for effortless setup.

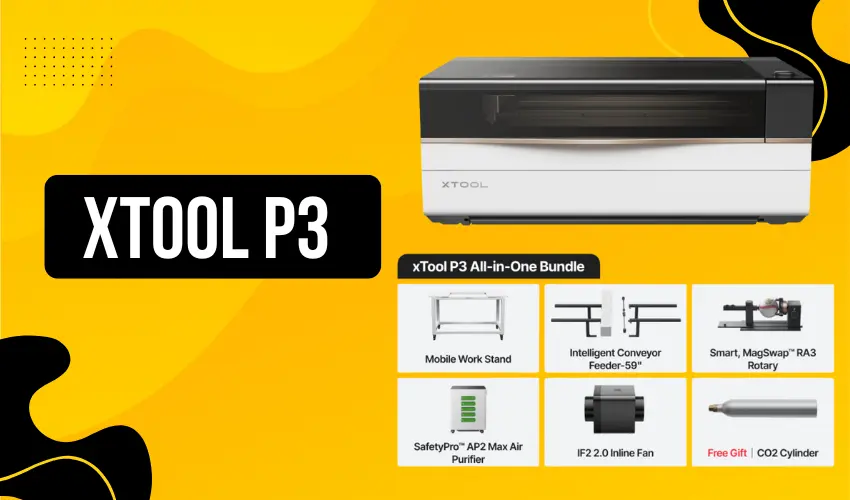

xTool P3 Accessories & Extensions: Must-Have Add-Ons for Maximum Performance

The xTool P3 is powerful on its own — but to unlock its full potential, a few key accessories can make all the difference. These aren’t just “nice-to-have” add-ons; many of them are essential for productivity, versatility, and safety. Below is a breakdown of the most useful xTool P3 accessories and what they bring to your workflow.

Infrared (IR) Laser Module for xTool P3

The optional infrared module gives your P3 the ability to engrave on metals and sensitive plastics that standard CO₂ lasers can’t handle. It’s perfect for marking stainless steel, aluminum, coated metals, and ABS plastic with stunning precision.

While it’s not yet widely available, xTool has confirmed an official release is coming soon. This upgrade is ideal for creators who want to expand into metal jewelry, electronics, or industrial part marking.

Best For: Metal engraving, coated plastics, and high-precision marking.

RA3 Smart Rotary Attachment

Take your creativity 360° with the xTool RA3 rotary module. This advanced rotary tool allows you to engrave round and cylindrical objects — like mugs, bottles, glasses, or tumblers — with automatic height adjustment and LiDAR mapping for perfect precision.

It’s a game-changer for small businesses, Etsy sellers, and gift shops looking to customize curved products in batches.

Best For: Cylindrical engraving and personalized products.

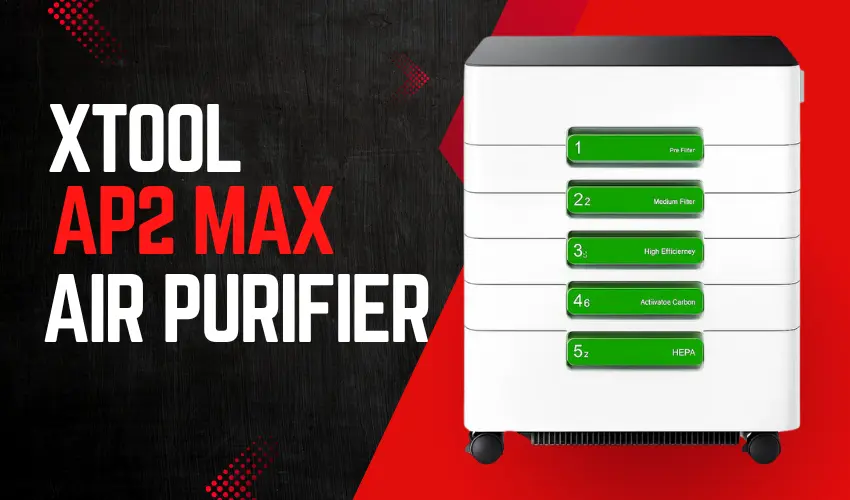

xTool SafetyPro Air Purifier

When working with an 80W CO₂ laser, air filtration is essential. The xTool SafetyPro Air Purifier eliminates smoke, odors, and fine particles, keeping your workspace clean and safe.

Available in multiple versions (including the AP2 and AP2 Max), it’s designed to match the P3’s power output. This makes it ideal for home studios, classrooms, and shared makerspaces without dedicated ventilation systems.

Best For: Clean air, odor control, and safe indoor operation.

Smart Conveyor Feeder

Turn your xTool P3 into a continuous-feed laser cutter with the Smart Conveyor Feeder. This powerful accessory automatically advances materials, enabling you to work on extra-long designs or batch jobs hands-free.

It’s a must-have for small manufacturers and production workshops looking to scale up productivity and reduce setup time.

Best For: Batch production, long workpieces, and automation.

Dedicated Work Table for the xTool P3

Designed specifically for the P3, this custom xTool table provides a stable, ergonomic, and perfectly sized workspace. It supports additional accessories like the conveyor feeder for seamless integration.

Best For: Stability, ergonomics, and integrated setups.

Cooling & Maintenance

- Uses propylene glycol antifreeze mixed with distilled water (varies by temperature).

- Operating Temp: 10°C–30°C

- Humidity: < 90%

- Laser Tube Replacement: ~10,000 hours lifespan.

- Weekly Cleaning: Baseplate, mirror, and lens.

- Monthly Check: Fans and cooling system.

Software & Connectivity

Software | Connection Options |

|---|---|

xTool Studio (PC only) | USB or Wi-Fi (2.4G / 5G) |

Bluetooth | BLE 5.1 |

Lenses & Focus Options

Lens Size | Focal Length | Best For |

|---|---|---|

S (38.1 mm) | 0.18 mm spot | Fine engraving |

M (50.8 mm) | 0.2 mm spot | General use |

L (63.5 mm) | 0.23 mm spot | Deep cutting |

Common FAQs

1. Does xTool P3 need calibration after unboxing?

No. It’s pre-calibrated but check optics after shipping.

2. Can P3 use CO₂ gas cylinders?

Yes. Supports 0.6L bottles with M18×1.5 threads (min. 400g CO₂).

3. Can it detect different material heights automatically?

Not multiple at once—auto mode focuses on the highest point.

4. Does it come with an air purifier or honeycomb panel?

The purifier and honeycomb panel are sold separately.

5. What maintenance is required?

Weekly cleaning, monthly checks, and using purified water for cooling ensure longevity.

What Makes the xTool P3 Stand Out

Industrial-Level Power & Productivity

Compared to many desktop lasers, the P3’s 80W CO₂ laser offers much greater cutting depth and speed. For example, it can cut thick wood panels or heavy acrylic slabs in one pass, which many lower-powered machines struggle to do.

Combine that with a large workbed and a high feed rate (1200 mm/s), and you have a machine suited for batch production or larger custom work rather than only small craft items.

Large Format, Big Flexibility

The 36″ × 18″ bed means you can handle big signage, large panel work, or multiple smaller pieces in one run. That dramatically expands what you can create in a single job versus smaller lasers. It also means less setup time for multiple pieces.

Smart Automation & Workflow Enhancements

xTool’s new ACST Intelligent Workflow System introduces true “place your material and go” automation.

It combines:

- Auto-Positioning: Dual cameras, including a 16MP panoramic view, give real-time workspace visibility for perfect design alignment.

- Autofocus: Built-in LiDAR Ranging automatically measures material height and adjusts the laser focal point with precision.

- AutoLift Base: Automatically sets the correct Z-height, eliminating manual calibration.

- AI Optimization: Smart algorithms auto-nest designs for material efficiency and stitch together large projects seamlessly with the optional conveyor feeder.

This intelligent automation saves setup time and enhances accuracy—ideal for busy makers and production environments.

Versatile Material Capability

While CO₂ lasers are traditionally suited to non-metals (wood, acrylic, leather, fabric, etc.), the P3’s optional 5-W IR (1064 nm) module opens the door to metal engraving and plastics. This “expandability” adds future-proofing.

Rotary Engraving, Reinvented

The optional Smart RA3 Rotary Attachment introduces 360° LiDAR mapping for accurate 3D previews and batch engraving capabilities. Unlike the P2S’s manual rotary, this system is faster, more precise, and completely automated—perfect for cylindrical products like tumblers, mugs, or glassware.

Pro-Level Safety & Build

With a Class 1 enclosure, flame/overheat detection, automatic shut-off, and a robust build, the P3 is more safety-ready than many craft lasers.

It features:

- Multi-layer safety sensors with an advanced Perception System for real-time hazard monitoring.

- A built-in CO₂ Active Fire Suppression System, which detects and extinguishes fires automatically—no need for the optional fire safety add-on used with the P2S.

This makes the P3 especially suited for schools, studios, and shared makerspaces where safety and compliance are critical.

Who Is The xTool P3 Laser Machine For?

- Small businesses or production studios that need higher throughput and larger formats rather than just occasional hobby use.

- Custom signage, large-format engraving/cutting, batch jobs where speed, area, and efficiency matter.

- Makers who plan to scale their operations, diversify materials (including metals), or offer premium services.

- Users who value automation and workflow efficiency, not just raw specs.

xTool P3 Limitations & What to Consider

- Footprint & cost: With its large size and industrial power, you’ll need adequate space, ventilation, and power supply. It’s more than a typical craft-room machine.

- Extraction / exhaust requirements: High-power cutting generates more smoke, debris and heat—so you’ll need proper air extraction and ventilation.

- Pricing vs need: If your workflow is modest (small items, occasional use), a lower-power laser may be more cost-efficient.

- Learning curve & maintenance: With automation features comes more complexity—calibration, maintenance, training may matter.

- Optional IR module: If you need metal engraving, check whether the IR module is available, as it has not yet been released.

Recommended Use Cases & Material Examples

- Wood signage/panels: Engrave and cut large plywood or hardwood signage in one pass.

- Acrylic fabrication: Large sheets of cast acrylic can be cut or engraved with crisp edges.

- Leather/fabric goods: Batch cut or engrave wallets, bags, patches in one go.

- Metal/plastic engravings (with IR module): Engrave stainless steel, aluminum nameplates, coated metals, plastics.

- Curved/cylindrical work: With accessories like a rotary attachment, the P3 can handle larger curved items (e.g., vases, tumblers) thanks to its automation features.

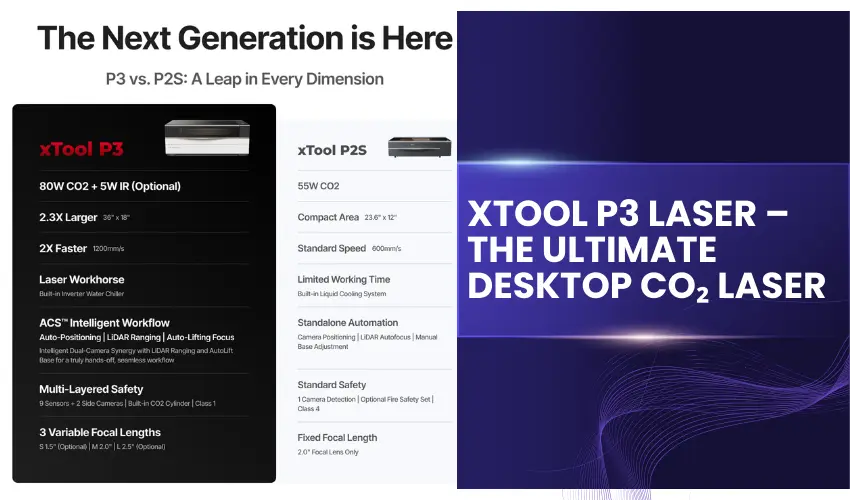

Comparison Table: xTool P3 vs P2S vs S1

Feature | xTool P3 (80W CO₂) | xTool P2S (55W CO₂) | xTool S1 40W Diode |

|---|---|---|---|

Laser Type | Sealed CO₂ Laser Tube | Sealed CO₂ Laser Tube | Diode Laser Array |

Laser Power | 80 W CO₂ (optional IR 5 W module for metal engraving) | 55 W CO₂ (optional IR module) | 40 W Diode Laser |

Work Area | 36 × 18 in (915 × 458 mm) | 26 × 14 in (680 × 360 mm) | 19 × 12 in (498 × 319 mm) |

Engraving Speed | Up to 1,200 mm/s | Up to 600 mm/s | Up to 600 mm/s |

Z-Height / Object Thickness | Up to 8.6 in (220 mm) AutoLift Base | 2.5 in (65 mm) Adjustable Tray | 2 in (50 mm) Adjustable Tray |

Supported Materials | Wood, Acrylic, Leather, Glass, Paper, Rubber, Fabric, Coated Metals (with IR) | Wood, Acrylic, Leather, Fabric, Glass | Wood, Leather, Acrylic (opaque only), Fabric (light) |

Connectivity | Wi-Fi, USB, Bluetooth, LAN | Wi-Fi, USB, LAN | Wi-Fi, USB |

Smart Features | Dual Cameras + LiDAR Autofocus + AutoLift Bed + Material Recognition | Dual Cameras + Autofocus | Camera Positioning + Safety Sensors |

Compatible Software | xTool Creative Space (XCS), LightBurn | xTool Creative Space (XCS), LightBurn | xTool Creative Space (XCS), LightBurn |

Air Assist & Filtration | Fully Integrated Air Assist & xTool SafetyPro AP2/AP2 Max Recommended | External Air Assist & Purifier Recommended | External Air Assist Optional |

Safety Certifications | Class 1 Laser Enclosure, Fire Sensors, Auto Shut-off | Class 1 Enclosure, Fire Sensors | Class 1 Safety Enclosure |

Price (USD) | $6,999 – $10,459 Check Latest Price Here | $3,799 – $6,939 Check Latest Price Here | $1,999 – $3,349 Check Latest Price Here |

Best For | Professionals / Small Manufacturers / High-Volume Production | Advanced Hobbyists / Small Businesses | Beginners / Crafters / Light Production |

Quick Takeaway

- Choose xTool P3 if you need industrial-grade power + automation for large-format jobs.

- Choose P2S for balanced power and affordability in professional hobby use.

- Choose S1 40W for budget-friendly precision and lighter materials.

Frequently Asked Questions

What materials can the xTool P3 Laser cut and engrave?

The xTool P3 is a powerful 80W CO₂ laser capable of cutting and engraving a wide range of materials. It can cut wood, acrylic, leather, paper, fabric, and rubber with precision, and engrave coated metal, glass, and ceramics using its high-accuracy laser head. When paired with the optional IR module, it can even mark stainless steel and aluminum, making it ideal for both creative and industrial projects.

How does the xTool P3 compare to the xTool P2S or xTool S1?

Compared to the xTool P2S and S1, the xTool P3 offers greater power, a larger workspace, faster speed, and advanced automation. The P3 features an 80W CO₂ laser, dual cameras, LiDAR autofocus, and an AutoLift bed, making it suitable for thicker materials. It’s designed for professional makers, small manufacturers, and design studios, while the P2S suits advanced hobbyists, and the S1 is better for beginners.

Is the xTool P3 safe to use indoors?

Yes, the xTool P3 is a Class 1 laser with a fully enclosed design, built-in fire detection, and automatic shutoff for safety. When paired with the xTool SafetyPro AP2 Max Air Purifier, it effectively removes smoke, VOCs, and fine dust, making it safe for indoor workshops, schools, and studios.

How much does the xTool P3 Laser cost, and is it worth it?

The xTool P3 starts around $6,999 USD and can go up to $10,459 USD depending on configuration (e.g., with RA3 rotary, intelligent conveyor feeder, or mobile work stand). Considering its industrial-grade performance, smart automation, and material versatility, it’s one of the best-value professional CO₂ lasers for creators, small businesses, and production workshops.

Do I need to buy a water chiller and air assist pump for the xTool P3?

No — both systems are fully integrated into the xTool P3. The machine features a built-in inverter water chiller that maintains consistent cooling for the powerful 80W CO₂ laser, ensuring stable and reliable performance during long runs. It also includes a professional-grade air assist and smoke extraction system, eliminating the need for external units. This all-in-one design is a major upgrade over previous xTool models, offering a cleaner setup and improved efficiency.

Is the xTool P3 compatible with LightBurn?

The xTool P3 is built to integrate perfectly with xTool’s own software, xTool Creative Space (XCS), offering full control over its intelligent features—including dual-camera alignment and LiDAR-powered autofocus. While it’s technically compatible with LightBurn, users should note that some of the P3’s smart automation features may not function due to xTool’s closed API. This means tasks like manual focusing and positioning may be required when using third-party software.

How does the xTool P3 auto-focusing system work?

The xTool P3 features an advanced LiDAR Ranging System that accurately measures the distance to your material’s surface in real time. Using this data, the motorized AutoLift Base automatically adjusts the height for optimal focus, ensuring perfect precision. This intelligent system completely removes the need for manual focusing tools or calibration steps.

Final Verdict

The xTool P3 is one of the most advanced desktop CO₂ laser cutters currently available. It offers high power, large format, smart automation, and pro-grade safety — making it ideal for makers who are serious about production, scaling their workflow, or offering premium custom work.

If you’re using a lower-power machine now and hitting limitations in size, speed or material flexibility, the P3 is a worthy upgrade. On the other hand, if your needs are modest or occasional, it may be more machine than necessary.

In short: If you need “ultimate” for the desktop CO₂ category, the xTool P3 delivers. Just make sure your workflow, budget and space match its capabilities.