When you want to make intricate designs on wood, nothing does it better than a laser cutter. From everyday items like coasters and clocks to art pieces and decor items, cutting wood with a laser cutter will result in jaw-dropping designs. But there’s a caveat – a laser engraver is limited to the depth it can cut in wood. So you have to choose the right wood thickness as well as the right laser cutter before you get started on your project.

How thick of wood can a laser cutter cut?

Laser cutters can cut wood with a thickness of up to 30 mm. However, most laser cutters are more effective when the material thickness ranges from 0.5 mm to 12 mm. Additionally, the thickness of wood that can be cut with a laser cutter largely depends on the wattage of the laser machine. A higher wattage machine can cut through thicker wood faster than a lower wattage one. For best results, go for laser cutters with a wattage of 60-100.

This guide covers everything you need to know to choose the right laser cutter for various wood thicknesses as well as the best wood for laser cutting:

Table of Contents

What Determines How Thick Wood a Laser Cutter Can Cut?

1. Laser Power (Wattage)

The wattage of your laser cutter is the most important factor. More power equals deeper and faster cuts.

Note: Multiple passes may be required at lower wattages for thicker materials.

2. Wood Type

Softwoods (like pine, cedar, balsa) are easier to cut than hardwoods (like oak, maple, walnut). Hardwoods are denser and require more power to achieve the same cut depth.

3. Grain & Resin Content

Woods with high resin or inconsistent grain may burn unevenly. Plywood, for example, varies in quality and sometimes includes glue layers that resist cutting.

4. Air Assist & Focus

Using air assist improves cut quality by blowing away smoke and debris. Proper focus ensures the laser beam stays sharp for deeper penetration.

What are the common types of laser cutters for wood?

In addition to wood thickness, you must also select the right laser cutter for your project because laser cutting machines are not equal. Different laser machines are designed for different materials and some are better suited for engraving as opposed to cutting. The following are the two broad categories of laser machines that are best suited for wood cutting projects.

Semiconductor Diode Lasers

These machines are generally small and are therefore meant for smaller laser cutting projects. While they are often used for cutting cardboard and paper, they may also come in handy for creating images on some wood materials as well.

However, for this to work, you will need a couple of passes and the wood needs to be soft too. Semiconductor diode lasers pack a wattage ranging from 5 – 40W.

Semiconductor Diode Laser Wood Cutting Thickness Guide

Laser Power | Max Cutting Thickness (Softwood) | Max Cutting Thickness (Hardwood) | Notes |

|---|---|---|---|

5W | Up to 3mm (1/8″) | 1.5–2mm | Best for engraving or very thin materials; multiple passes required |

10W | 3–6mm (1/8″–1/4″) | 2–3mm | Good for hobby cutting and crafting with light woods |

20W | 6–10mm (1/4″–3/8″) | 3–5mm | Cuts faster, suitable for thicker plywood and denser woods |

40W (Diode) | 10–15mm (3/8″–5/8″) | 6–8mm | High-performance diode lasers, close to CO₂ capability on softwood |

Important Notes:

- Values are approximate and depend on material type, air assist, focus, and number of passes.

- Always run test cuts to determine best speed/power settings.

- Hardwoods and plywoods may require slower speeds or more passes, even at higher wattages.

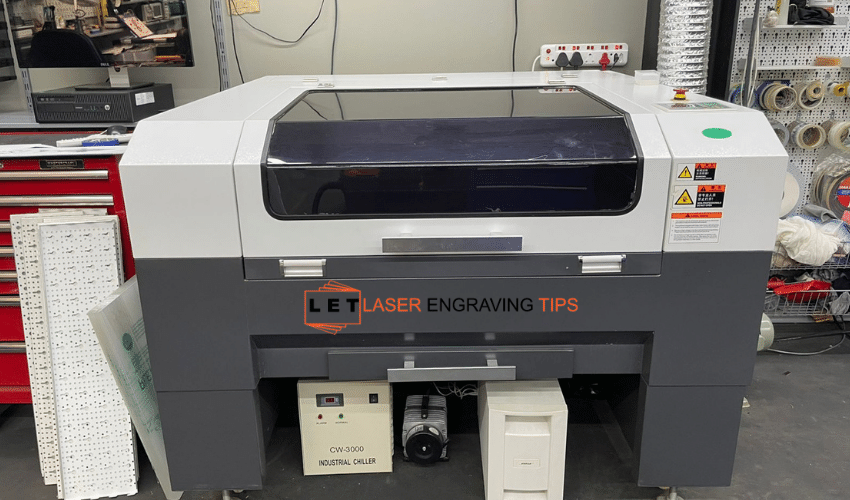

CO2 Laser Cutters

Co2 laser cutters are the most ideal for wood cutting and engraving projects. If you are looking to cut a couple of designs for the sheer fun of it, then then a semiconductor diode laser could suffice but if you are looking to set up a serious laser cutting/engraving business, then you want to go with a CO2 laser cutter.

Co2 laser cutters have a wattage of between 30 watts all the way to 300 watts which makes them perfect for most wood cutting projects.

CO₂ Laser Cutter Wood Cutting Thickness Guide

Laser Power | Max Cutting Thickness (Softwood) | Max Cutting Thickness (Hardwood) | Typical Use & Notes |

|---|---|---|---|

40W | 3–6mm (1/8″–1/4″) | 2–3mm | Great for thin materials, hobby projects, multiple passes needed |

55W | 6–8mm (1/4″–5/16″) | 3–4mm | More cutting power for small production use |

60W | 8–10mm (5/16″–3/8″) | 4–5mm | Balanced for general-purpose use |

80W | 10–12mm (3/8″–1/2″) | 6–8mm | Ideal for medium-thickness wood and plywood |

100W | 12–15mm (1/2″–5/8″) | 8–10mm | Popular in workshops and small businesses |

120W | 15–18mm (5/8″–11/16″) | 10–12mm | High performance for commercial projects |

150W | 18–20mm (11/16″–3/4″) | 12–15mm | Great for thicker hardwood and high-volume cutting |

300W | 25–30mm (1″–1 1/8″) | 18–20mm | Industrial-grade cutting; handles thick hardwoods and large-scale production |

Important Notes:

- Results vary depending on wood type, resin content, grain, and quality.

- Softwoods cut more easily than hardwoods due to lower density.

- Use air assist and proper focus for cleaner cuts and reduced charring.

- Multiple passes may be needed for hardwoods or precision edges.

- Always test settings before full production runs.

Which wood should not be laser cut?

Not every wood you come across is ideal for your laser cutting project. The following are some types of woods that you shouldn’t use.

- Plywood: plywood has glue, which when in rich quantity tends to inhibit laser cutting resulting in uneven cuts/engraving.

- Exotic Hardwoods: Since this wood type is tremendously compact, the process of engraving is extremely difficult.

- Oleander: This wood will release toxic fumes when laser cut or laser engraved.

- Fiberboard: The wood fibers have glue which constrains the cutting and produces deadly fumes and poor outcomes.

- Bamboo and Oak: These woods are richly fibrous, which yields uneven depth.

Also Read: Are Laser Engraving Fumes Toxic?

Which is the best wood for laser cutting?

Most laser cutters work great with softwoods that have no grain patterns. For that reason, some of the best wood types for laser cutting include white pine, oak, cedar, balsa and basswood.

PRO TIP: When working with softwoods (Redwood, Cedar, etc.), the laser power required is less while for hardwoods (Cherry, Oak, Mahogany, etc.) more laser power is required.

Best Softwoods to Cut:

- Basswood – Very easy to cut and engrave

- Balsa – Lightweight, ideal for models

- Pine – Affordable and common

Best Hardwoods to Cut:

- Maple (Thin sheets) – Dense, clean cuts with high power

- Cherry – Rich finish when engraved

- Birch Plywood – Popular for crafts, varies in glue type

Tips for Laser Cutting Thicker Wood

- Use Slower Speeds: Let the laser linger longer to penetrate deeper.

- Increase Passes: Make multiple passes to gradually cut through thicker pieces.

- Raise the Material: Elevate your wood for better airflow and smoke dissipation.

- Use Air Assist: This helps reduce charring and keeps your lens clean.

- Always Test First: Every batch of wood is different—run test cuts!

What If My Laser Can’t Cut Through My Wood?

If your laser isn’t cutting all the way through, check the following:

- Lens is clean and properly focused

- Laser mirrors are aligned

- Power and speed settings are optimized

- Air assist is functioning

- Material is flat and not warped

Is MDF Safe to Laser Cut?

MDF (medium-density fiberboard) is made of wood wastage fibers that are compressed and bonded using glue and resin. So in the strict sense of the word, medium-density fiberboard is not really a type of wood.

Even though it is possible to laser cut MDF, it comes with some risk. For starters, laser cutting MDF releases excessive dust particles and that can result in health issues. MDF could also release volatile organic compounds which can be a health hazard. You should therefore only laser cut MDF in a well-ventilated room. You may also want to use a fume extractor in addition to other protective gear.

To improve the ventilation in your workspace it would be advisable to install a suitable exhaust fan. On the below link you will find more information on the top 5 laser engraver exhaust fan options.

Is Laser Cutting Wood Dangerous?

Laser cutting wood may pose health and safety risks, especially when done on an industrial scale or setting. When a laser is cutting wood, there is the production of and exposure to particulate matter, chemicals, and gases. The particulate matter produced can cause irritation of the nose, eyes, skin, and respiratory tract. Also, lasers can blind or burn you, and hence using personal protective equipment is a necessity.

Caution: Wood materials are highly flammable. You should, therefore, keep a close eye during the cutting process to avoid accidents. Always a good idea to keep a fire extinguisher handy for any sudden flare-ups. We use the First Alert Professional Fire Extinguisher in our workshop. More information can be found here.

Frequently Asked Questions

How thick of wood can a laser cutter cut?

It depends on the laser’s wattage and the type of wood. A 40W CO₂ laser can typically cut up to 1/4″ (6mm) softwood, while a 100W CO₂ laser can cut up to 1/2″ (12mm) or more. Diode lasers (5W–20W) usually max out around 1/4″ with multiple passes.

What type of wood is easiest to cut with a laser cutter?

Softwoods like balsa, pine, and basswood are the easiest to cut because they are less dense. They require less power and produce cleaner results compared to hardwoods like oak or maple.

Can I cut hardwood with a low-powered laser like 40W or 5W?

Yes, but with limitations. A 40W CO₂ laser can cut very thin hardwood (1/8″ or less) with slower speeds and multiple passes. A 5W diode laser is better suited for engraving or cutting thin softwood; hardwood is often too dense for full cuts.

What helps improve wood cutting performance with a laser?

Key factors include correct focus, clean lenses, aligned mirrors, using air assist, and flat, well-supported material. Slowing down the speed or making multiple passes can also help with thicker cuts.

Why won’t my laser cutter cut through thicker wood?

Common reasons include incorrect focus, insufficient power, dirty optics, poor material quality, or lack of air assist. Also, the wood may be too thick or dense for your machine’s wattage. Always test with recommended speed/power settings and ensure your machine is properly maintained.

Final Thoughts

It is a good idea to test out some waste wood and keep fine-tuning the settings on the laser cutter until you have the perfect setup. You can then move to the real material after you are sure of the results. In addition to testing, get the right laser cutter and the appropriate wood, and your project will be a success.