Laser marking on anodized aluminum has become a game-changer for industries and small businesses that demand durable, high-contrast identification.

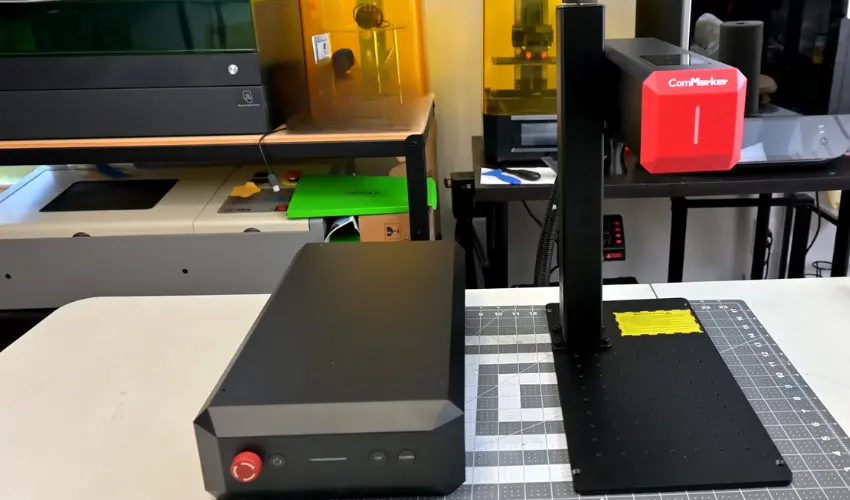

While anodized aluminum has long been the go-to material for marking, MOPA fiber lasers, like the ComMarker B6 60W, take things to the next level by allowing for deep black, high-contrast markings.

Black marking on anodized aluminum can only be achieved with an MOPA laser. Its short-pulse technology allows deep color change, whereas standard fiber lasers are limited to producing white and grey markings.

Table of Contents

In this guide, we’ll break down how black marking works, why the ComMarker B6 is the right tool for the job, and the step-by-step process to achieve perfect results.

What is Black Marking on Anodized Aluminum?

Black marking is a surface-level oxidation process created by a MOPA fiber laser. Instead of engraving deep grooves, the laser manipulates the aluminum’s oxide layer, generating a permanent black color with excellent contrast.

This method is ideal for industries requiring readable, permanent marks that can withstand wear, cleaning, and environmental stress, such as:

- Serial numbers & barcodes

- QR codes for traceability

- Logos & branding

- Compliance marks (CE, FCC, etc.)

- High-end consumer products (electronics, tools, luxury items)

Why Use the ComMarker B6 60W MOPA Laser for Black Marking On Anodized Aluminum?

The ComMarker B6 60W is specifically designed for professional-grade marking on metals like anodized aluminum. Here’s why it stands out:

- MOPA Technology – Unlike standard fiber lasers, MOPA allows fine-tuning of pulse duration and frequency, making it possible to create deep black markings on anodized aluminum.

- High Power (60W) – Ensures faster processing speeds and more consistent results, even for detailed markings like micro text or QR codes.

- Durability of Marks – The black marks created resist abrasion, chemicals, and UV exposure.

- Industrial-Grade Performance – Perfect for continuous use in manufacturing, while also versatile enough for small businesses and custom projects.

- Precision – Capable of marking with resolutions up to 8K, ensuring sharp, clear black contrast on anodized aluminum surfaces.

Step-by-Step: How to Achieve Black Marking on Anodized Aluminum

Step 1: Prepare the Surface

- Clean the anodized aluminum thoroughly with alcohol to remove dirt, oil, or oxidation.

- Ensure the surface is smooth and clean.

Step 2: Set Up Your ComMarker B6

- Position your anodized aluminum piece securely on the worktable.

- Adjust the focus using the auto-focus or manual focusing system for accurate results.

Step 3: Choose the Correct Parameters

The magic of black marking lies in pulse duration and frequency control. Suggested starting settings for the B6 60W:

Setting | Value |

|---|---|

Power | 80 – 100% |

Speed | 500 - 1200mm/s |

Frequency | 30 – 300 kHz |

Q‑Pulse Width | 4 – 10 ns |

Line Interval | 0.001 – 0.015 mm |

Tip: Run a test grid first to fine-tune your parameters based on your specific anodized aluminum

Step 4: Apply Your Design

- Import your design into the laser software (EZCAD is commonly used).

- Vector files (SVG, AI, DXF) are best for logos and text.

- Raster images can also be used but may require adjustments for clarity.

Step 5: Begin Marking

- Start the laser marking process.

- Observe to ensure the beam is consistent and that black contrast is forming evenly.

Step 6: Post-Processing

- Wipe down the surface with a clean cloth to remove residue.

- No sealing is required—the black marking is already permanent and scratch-resistant.

Quick Troubleshooting Guide: Black Marking on Anodized Aluminum with MOPA Laser

Mark Looks Gray Instead of Black

- Fix: Lower the speed or increase the power slightly to allow more oxidation.

- Fix: Adjust frequency upward (200–300 kHz) and use shorter pulse widths (4 – 10 ns).

- Cause: Insufficient oxidation or too shallow surface interaction.

Mark Appears Brownish or Faded

- Fix: Reduce power or frequency slightly.

- Fix: Ensure surface is clean (wipe with isopropyl alcohol before marking).

- Cause: Overheating of the anodized aluminum surface causing discoloration instead of controlled oxidation.

Marking is Uneven or Blotchy

- Fix: Increase the overlap of scan lines by lowering speed or increasing line spacing precision.

- Fix: Check lens focus—make sure material is at the correct focal distance.

- Cause: Poor beam focus or inconsistent passes across the surface.

Mark Rubs Off Easily

- Fix: Use slightly higher power and lower speed to deepen oxide layer bonding.

- Fix: Run a second pass with reduced power to stabilize the black effect.

- Cause: The oxide layer is too thin or superficial.

Reflection Issues (Laser Not Absorbing Properly)

- Fix: Apply a light spray of laser marking solution.

- Fix: Slightly angle the part to reduce direct reflection back into the lens.

- Cause: Poor quality anodized aluminum coating reduces energy absorption.

Pro Tip: Always start with a test matrix (varying speed, power, and frequency) on a scrap piece of the same anodized aluminum. This saves time and ensures perfect results before production

Advantages of Black Marking on Anodized Aluminum

- High Contrast: Deep black finish that’s easy to read.

- Durability: Resistant to fading, scratching, and harsh chemicals.

- Non-Destructive: Surface is altered without removing large amounts of material.

- Traceability: Perfect for industrial serial numbers and compliance requirements.

- Aesthetic Appeal: Clean, professional look for consumer goods.

Applications of Black Marking On Anodized Aluminum with the ComMarker B6 MOPA Laser

The 60W MOPA Fiber Laser excels in industries such as:

- Electronics: Marking housings, connectors, and PC components.

- Aerospace & Automotive: Serial numbers, safety labels, and compliance marks.

- Medical Devices: Surgical tools, implants, and instruments.

- Promotional Items: Custom logos on metal pens, bottles, and accessories.

Frequently Asked Questions

What is black marking on anodized aluminum with a MOPA laser?

Black marking is a process where a MOPA fiber laser alters the aluminum’s surface oxide layer to create a deep black, high-contrast mark without removing significant material. Unlike engraving, which cuts into the metal, black marking is a surface-level modification that produces durable, permanent markings ideal for barcodes, serial numbers, and logos.

Why is a MOPA laser better for black marking anodized aluminum than a standard fiber laser?

A standard fiber laser lacks the ability to finely adjust pulse duration and frequency, which are critical for achieving deep black marks. A MOPA laser (Master Oscillator Power Amplifier), like the ComMarker B6 60W, allows you to control pulse width and frequency precisely. This makes it possible to oxidize the surface evenly, resulting in a consistent, high-contrast black finish on anodized aluminum.

How durable is black marking on anodized aluminum compared to engraving?

Black marking with a MOPA laser is extremely durable because it alters the aluminum oxide layer rather than applying a superficial coating. The markings are resistant to scratches, abrasion, chemicals, and UV exposure. However, deep engraving might still be preferred in applications where physical wear is extreme (such as tools that undergo constant impact).

What industries benefit most from black marking anodized aluminum with a MOPA laser?

Black marking is widely used across industries that require permanent, readable, and high-contrast identification, including:

Medical devices (surgical tools, implants, compliance marks)

Electronics (QR codes, logos on housings, connectors)

Aerospace & Automotive (serial numbers, safety labels)

Luxury goods & branding (engraving logos on consumer products like watches, golf clubs, and pens)

Industrial manufacturing (traceability codes, barcodes, and compliance markings)

Final Thoughts

The ComMarker B6 60W MOPA Fiber Laser is one of the best tools available for black marking on anodized aluminum. Its powerful laser, MOPA pulse control, and precision software enable professionals and small businesses alike to create permanent, high-contrast, and professional-grade results.

If you want durability, readability, and speed in your anodized aluminum marking projects, the ComMarker B6 is the laser engraver we recommend.