Titanium is a remarkable material—lightweight, incredibly strong, and highly resistant to corrosion. These properties make it a favorite in industries like aerospace, medical, jewelry, and consumer goods.

But when it comes to customization, identification, and decorative finishes, laser etching titanium is the most efficient, precise, and permanent method available.

Table of Contents

In this guide, we’ll cover everything you need to know about laser etching titanium, from the process itself to the best machines, applications, and tips for success.

What is Laser Etching on Titanium?

Laser etching is the process of using a focused laser beam to create permanent marks on the surface of titanium. Unlike engraving, which removes material, or annealing, which alters the oxide layer to create color, etching creates shallow, high-contrast marks by heating and slightly oxidizing the surface.

This makes it ideal for barcodes, serial numbers, logos, and text, as well as decorative or artistic designs.

Why Titanium is Ideal for Laser Etching

Titanium reacts extremely well to laser energy due to its material properties:

- High Strength & Durability – Marks last for the life of the part.

- Corrosion Resistance – Etched areas do not compromise titanium’s integrity.

- Color-Changing Capability – By adjusting laser settings, titanium can display a wide range of colors due to oxide layer thickness variations.

- Biocompatibility – Perfect for medical implants and surgical tools where identification is essential.

Best Machines To Laser Etch Titanium

Not every laser is capable of effectively marking titanium. Here are the best options:

Fiber Lasers (20W–60W)

- Best for deep etching, serial numbers, barcodes, and permanent industrial marking.

- Produces crisp, durable results.

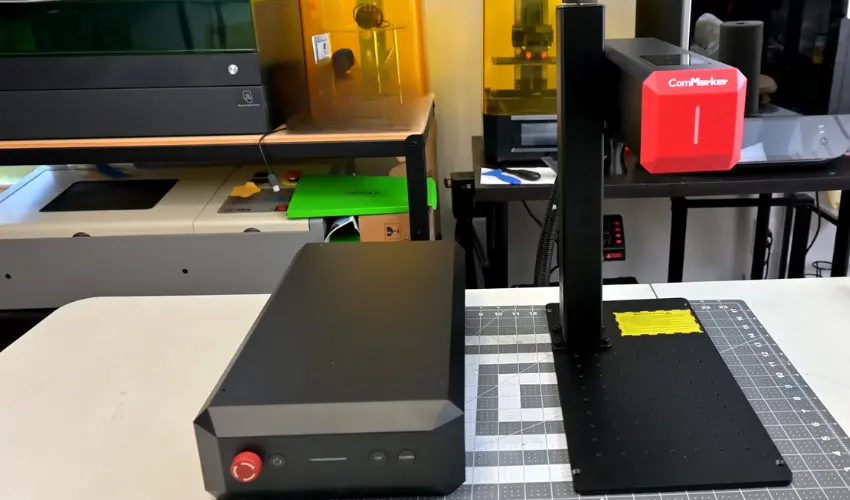

ComMarker B4 20W Fiber Laser Engraver

Best Budget Fiber Laser for Titanium

Why the ComMarker B4 20W Fiber Laser Is a Great Budget Option to Laser Etch Titanium (Under $1,500)

- High Value at an Affordable Price

Priced competitively under $1,500, the ComMarker B4 offers industrial-grade fiber laser performance without the premium cost typically associated with such capability. - Efficient Power for Titanium Marking

The 20W fiber laser delivers sufficient energy density to create crisp, permanent surface markings on titanium through oxidation without needing deep engraving. - Ideal for Small Business & Hobbyists

Its compact footprint and plug-and-play design make it accessible for startups, home shops, and small businesses aiming to produce durable product markings such as serial numbers, logos, or QR codes. - Superior Mark Quality

Capable of producing clean, high-contrast marks directly on bare titanium—no need for special coatings or sprays—this laser achieves professional end results on a budget. - Minimal Ongoing Costs

Unlike mechanical etching tools with consumables, the B4 requires no replacement parts beyond routine lens maintenance and power usage, keeping long-term costs low. - Expandable for Future Use

Should your business grow, the B4 can be integrated into automation setups or paired with software upgrades, making it a sustainable entry investment into laser marking workflows.

MOPA Fiber Lasers

- Allow color marking on titanium by controlling pulse width.

- Best for logos, decorative finishes, or branding.

ComMarker B6 60W MOPA Laser

Best Budget MOPA Laser for Titanium

Why the ComMarker B6 60W MOPA Is a Smart Choice To Laser Etch Titanium (Budget-Friendly Option Under $3,100)

- Exceptional Value

At under $3,100, the B6 delivers MOPA-level capabilities—like color marking and fine oxide-layer control—that typically cost much more in industrial systems. - Powerful & Efficient Performance

The 60W fiber laser provides ample power for precise titanium etching with quicker processing speeds and excellent depth control, making it ideal for both small-batch and moderate production workloads. - Versatile Marking Options

With its MOPA technology, the B6 can produce not only deep gray/black marks but also vivid colored engraving by manipulating pulse duration—perfect for decorative or branded titanium products. - Professional-Grade Results

Produces clean, sharp, high-contrast marks that are durable, corrosion-resistant, and suitable for serial numbers, medical instruments, aerospace parts, or luxury goods—without costly consumables. - Compact & User-Friendly

Designed for small workshops, the B6 is easy to set up, operate, and maintain. Its software interface is intuitive, lowering the learning curve for newcomers to laser marking. - Low Maintenance & Long-Term Reliability

Fiber lasers are known for their low upkeep. With minimal consumable parts—typically only the lens and protective glass—to replace over time, total ownership costs remain low. - Room for Growth

The B6’s capabilities allow creatives, jewelers, or small manufacturers to start with entry-level production and scale up into more advanced applications like color marking or higher-volume parts as their needs evolve.

How to laser etch titanium with a Fiber Laser

Here are some of the things you’ll need:

- A fiber laser machine: as is the case with other laser etching projects, you need a quality laser machine. Since the markings don’t run deep, a low-power laser will get the job done. As a rule of thumb, choose a Fiber Laser with a power rating of at least 20W or an MOPA Laser with a power rating of 60W. Anything less than that may leave an unpleasant shadow on your result.

- Editing software: to create your image, you’ll need editing software of some sort. This can be something as simple as Adobe Photoshop or CorelDraw as well as EzCad which is a specialized fiber laser marking software.

- Physical supplies: the job won’t be complete without a few supplies such as rubbing alcohol, goggles, gloves, and a cloth.

The laser engraving process

Before you roll up your sleeves, be sure once you start engraving that you wear your laser safety goggles. You don’t want the beam to cause any eye damage.

- The design phase

First and foremost, you need to create the image to be etched on your titanium. This can be a vector image or photo. It should be grayscale or black and white depending on your laser. The editing software should give you an idea of how the outcome will be. Make any changes as desired on the software. When satisfied, proceed to save the work on using software that is friendly to your laser.

The results of engraving are guaranteed to be exact and faultless when using fiber laser marking software like EzCad. Using EzCad to engrave intricate, high-resolution designs will guarantee perfect precision.

One of the most widely used professional marking programs is called EzCad, and it’s ideal for fiber laser marking business, laser enthusiasts, and craftspeople. It satisfies all user requests because of its robust image processing features, compatibility, and text processing.

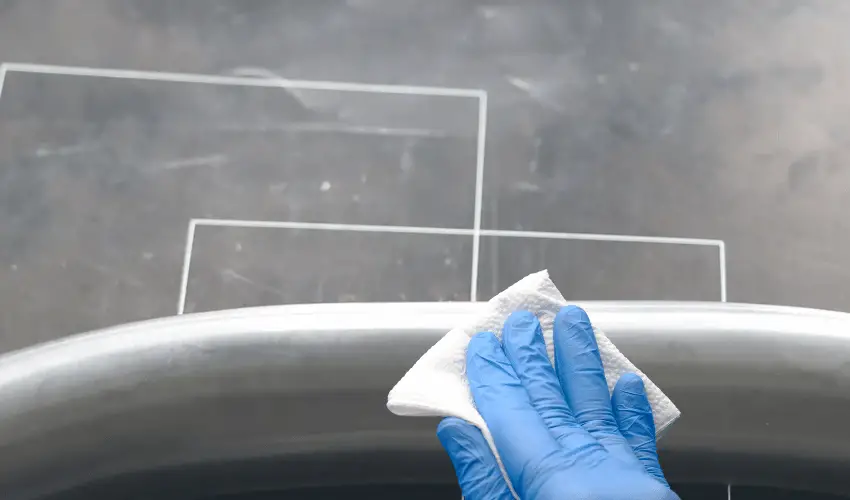

- Metal preparation

The next step is the preparation of the titanium for etching. First, put on your gloves and clean the material using rubbing alcohol and a cloth. This step will help you to get rid of any grease and dirt from the surface which could greatly reduce the quality of your work.

- Laser etching titanium

Power your laser in preparation for etching. Wear your safety goggles for this step. Refer to this article to see why this is important. Once you have turned the laser on, place your titanium material, and adjust the laser’s height and focus as needed.

If you are working with a curved material, it is going to be a little tricky but doable. All you have to do is find both the highest and lowest points and adjust the laser in the middle.

After adjusting the focus of the laser comes the exciting part of the process – etching. Begin by loading your image to the laser’s software. Set the speed and the power. Best to do some tests first to make sure sure the settings are correct

These are the starting settings for a 20W Fiber Laser Marker:

- Use the Titanium General Setting in EzCad

- Speed: 1300mm/s

- Power: 70%

- Frequency: 25 Khz

- Use the anneal setting for one pass to give an excellent gold finish

- Cleaning

With the laser etching phase done, remove your titanium from the laser and clean it using a soft dry cloth.

Comparison of Annealing vs. Color Marking on Titanium with a Laser

Feature | Annealing (Black/Gold Marking) | Color Marking |

|---|---|---|

Laser Type | Standard fiber laser or MOPA fiber laser | MOPA fiber laser required |

Pulse Settings | Longer pulses, lower frequency, lower power | Shorter pulses, high frequency with fine control |

Process | Heats the surface to change oxide layer thickness, no material removal | Precisely varies oxide layer thickness to create light interference colors |

Appearance | Deep black, Gold, high-contrast marks | Multiple colors (blue, gold, purple, green, etc.) |

Durability | Extremely durable, smooth surface, wear-resistant | Durable but colors may fade with heavy wear or abrasion |

Applications | Serial numbers, barcodes, industrial parts, medical tools | Logos, jewelry, personalization, decorative designs |

Surface Texture | Smooth, no engraving depth | Smooth, no engraving depth |

Best For | Functional, permanent identification | Aesthetic, branding, artistic projects |

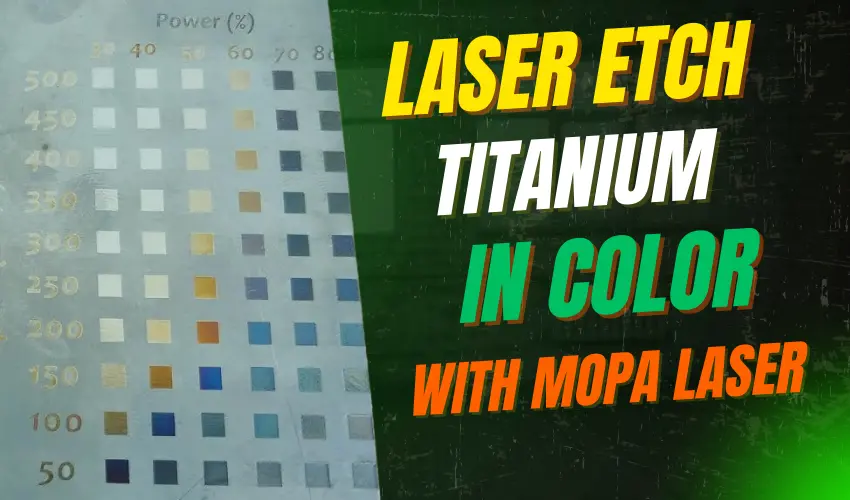

Laser Etch Titanium In Color With MOPA Laser

MOPA (Master Oscillator Power Amplifier) fiber lasers are the only laser type capable of producing stable color markings on titanium. By adjusting pulse width, frequency, and power, you can create vibrant and permanent color designs ranging from blue and purple to gold and green.

Step 1: Choose the Right MOPA Laser

- Recommended: 60W MOPA fiber laser (e.g., ComMarker B6 60W MOPA).

- A higher wattage laser allows faster marking speeds and richer color variation.

Check ComMarker B6 60W MOPA Laser Price Here

Step 2: Prepare the Titanium Surface

- Clean with isopropyl alcohol to remove oils, fingerprints, and oxidation.

- Smooth, polished surfaces yield more vibrant and even colors.

Step 3: Import Your Design

- Use EZCAD or compatible software.

- Convert your design into vector format for clean edges.

- Position and resize it according to your titanium piece.

Step 4: Set Your MOPA Laser Parameters

Color marking is achieved by controlling oxide layer thickness through specific combinations of:

- Power → Controls depth & heating.

- Frequency (200–400 kHz) → Higher frequency allows finer color control.

- Pulse Width (150–350 ns) → Determines heat transfer and oxide thickness.

- Speed → Slower speeds allow more color buildup.

Example Starting Settings for Colors (may vary by machine):

- Blue → 25% power, 250 mm/s, 250 kHz, 200 ns

- Gold → 30% power, 200 mm/s, 300 kHz, 200 ns

- Purple → 20% power, 150 mm/s, 300 kHz, 250 ns

- Green → 25% power, 100 mm/s, 350 kHz, 300 ns

Note: Always run a small color test grid on scrap titanium to dial in exact colors for your setup.

Step 5: Focus and Preview

- Use autofocus or manually set the correct focal length.

- Run a preview frame to confirm alignment before engraving.

Step 6: Laser Etch in Color

- Start the marking process and observe the color formation.

- Some colors may require multiple passes or slight parameter tweaks.

- Avoid excessive power, which can burn or distort colors.

Step 7: Clean and Finish

- After marking, wipe with alcohol to remove surface debris.

- The color is permanent and corrosion-resistant, embedded in the oxide layer.

Tips for Best Results

- Use lower power with higher frequency for vibrant colors.

- Polished titanium produces stronger colors than matte finishes.

- For consistent results, keep your workspace dust-free and maintain clean optics.

Frequently Asked Questions

Can titanium be laser etched?

Yes. Titanium is one of the best metals for laser etching because of its ability to form a stable oxide layer when exposed to a focused laser beam. This allows you to create permanent, high-contrast marks such as text, logos, barcodes, or even colored patterns without damaging the structural integrity of the metal.

Is laser etching titanium permanent?

Yes. Laser etching titanium creates marks that are permanent, heat-resistant, and corrosion-proof. Unlike surface printing, the etching process modifies the oxide layer or removes material directly, ensuring the design or code won’t fade, chip, or wear off over time—even in extreme conditions.

What watt laser to engrave titanium?

A 20W–30W fiber laser is sufficient for engraving titanium with black marks, while a 50W–60W MOPA fiber laser is ideal if you want faster processing or colored engravings.

Final Thoughts

Laser etching titanium is one of the most effective ways to customize and identify this strong, versatile material. Whether for industrial applications like aerospace and medical tools, or for creative projects like jewelry and branding, a fiber or MOPA laser engraver is your best choice.

By using the right machine, fine-tuning your settings, and following best practices, you can achieve stunning, permanent results on titanium every time.