Laser engraving is a popular technique for personalizing or highlighting the aesthetic qualities of many materials. This practice has advanced over the years, and now you can make complex designs with the help of an engraving machine without worrying about errors.

Laser engraving works on various materials, but can you laser engrave gold? Gold is a popular material for jewelry, decorations, and other luxury goods because of its inherent visual appeal, durability, and conductivity. It has a highly reflective surface and melts at a much lower temperature than most metals used to produce jewelry. A high-quality fiber laser is suitable for engraving gold items.

Let’s see how you can laser engrave gold.

Jewelry Engraving

Engraving creates patterns by cutting into a hard, usually flat surface. This process creates designs or adds initials to various metals, wood, and stones. It emerged from the Rhine Valley in Germany and northern Italy in the 15th century.

Early engravings were carried out on coins or decorative items such as spoons and plates. Some examples of engraving on mammoth tusks from over 13,000 years ago were also discovered.

Ancient Egyptians were the first to adopt engraving practices on decorative jewelry. They have examples of nicely carved gemstones made using simple tools to create shallow grooves. The idea was passed on to the following generations and is still adopted today.

Also Read: A Complete Guide on Learning How to Engrave Jewelry

In the modern age, many people look forward to engraving their jewelry with the designs and initials of their choice. Some people add memorable dates to their rings or bracelets, while others may prefer quotes. The options are endless.

Engraving can add charm to your jewelry and increase its value or importance. Every piece of jewelry has its own significance. Most people engrave their engagement or wedding dates on their jewelry. It’s important to understand that engraving techniques, tools, and types vary from material to material. Not every object will respond the same way to a particular kind of engraving.

As the jewelry is available in a wide range of material qualities, every type has the engraving method that suits it best. Some metals respond better to laser engraving, while others may be sensitive to it.

The engraving techniques have advanced over the years, from mechanical to laser engraving. Gold is highly in demand because of its value and visual appeal when it comes to jewelry. Engraving your gold jewelry may sound like a great idea to you, but can you laser engrave gold?

Understanding Laser Engraving

Back in the day, engraving was an art practiced by many and was limited to being carried out manually. Early engravers used tools such as chisels to carve out the material and create the desired design. Manual engraving is very limited today. Even if you find a manual engraver, it’s very expensive. Advancements in manual engraving and mechanical techniques have now led to contactless laser engraving.

Laser engraving works on the principle of vaporization. It creates a high-powered laser in a controlled environment. This laser provides an adequate amount of heat that vaporizes the material into fumes and leaves deeply engraved marks. This laser beam acts as a chisel, removing the layer from the material’s surface and incising permanent patterns.

The laser engraving service might be cheaper than manual engraving, but the cost of the laser engraver itself is high. The price of a laser engraver depends on its size, power, and brand. Entry-level engravers start at around $150 and can go up to tens of thousands of dollars.

The idea of customizing various items around you with engraving probably sounds appealing to you, but you may be wondering if you can laser engrave anything.

Almost any material can be personalized using a laser engraver. The only restriction is the size of the item to be engraved. If it’s too little, the laser beam won’t be able to focus on its narrow portions and engrave it properly.

Can You Laser Engrave Gold?

Gold is one of the densest metals, which might not be suitable for engraving by a normal laser engraving system. If you want to engrave gold, the fiber laser system is your best option to carry out the job with high precision without damaging it.

Gold is a metal that does not corrode or tarnish, making it a very appealing material to use. It’s visually pleasing, workable, and has been widely used for making jewelry for thousands of years. Thanks to its unique characteristics and value, gold is a material that holds economic value and is accepted universally as an exchange for goods and services globally.

“But gold shines like fire blazing in the night, supreme of lordly wealth.” – Pindar, Olympian Odes. Gold has been known as a symbol of wealth, mostly used for ornaments and jewelry.

It is molded into various shapes and is available as earrings, necklaces, watches, rings, and every other fashion accessory. Some wealthy people around the world have even wrapped their automobiles in gold as a symbol of their wealth.

When it comes to customization, people prefer to design gold items tailored to their choice. It can be molded into ornaments of various designs. The most common types of customizations used for gold are etching and engraving.

Etching is a process where strong acids are used for printmaking and creating designs on the surface of a metal plate. The acid reacts with the metal’s surface and leaves a permanent mark. Engraving works without using any extra chemicals. It cuts into the material and creates patterns. People are moving more toward engraving due to its ability to create complex designs with minimal room for errors.

Customization can give you a personalized item with your initials on it. Who doesn’t want to surprise their significant other with their initials engraved on a special piece of jewelry, making them feel even more special? Initially, engraving was carried out by hand, but now you can use a laser to engrave your gold items.

It’s important to note that not every type of laser is suitable for engraving gold. As it has a highly reflective surface, one needs a laser with a higher density to work on it.

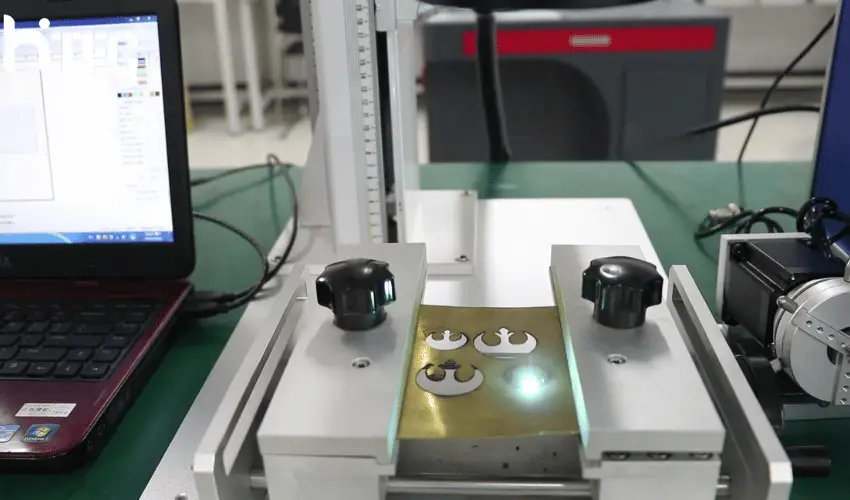

A pulsed fiber laser is a preferred technology to engrave items made of gold. It has a high-density laser, allowing the material to absorb heat quickly. Its parameters allow it to work in a controlled environment and carry out the engraving on delicate surfaces.

Benefits of Engraving Gold With a Laser

There are several advantages to using fiber lasers on your gold items that make it the best method for engraving.

Easy to Use

Back in the day when mechanical engraving was practiced, it required exquisite craftsmanship to carry out delicate tasks, which was not everyone’s cup of tea. They had to go through extensive training and years of practice to master engraving.

Laser engraving has made the task a lot easier. You just need to buy a laser engraver and install it. In addition, you need to understand the engraving software, and you are all set. Some of the already-developed templates are also available online, which you can download and adjust according to your needs.

Quick Processing

Unlike traditional engraving, laser engraving does not require a great deal of attention or focus. You just need to submit the design to engraving software, which will swiftly interpret the design and push the engraver along the guided pattern.

Higher Precision

Machine-guided engraving has a smaller room for error, and the narrow laser of the engraver adds to the ability to engrave with high precision, even in narrow areas.

Minimal Maintenance

Laser engraving is a non-contact process that does not have any risks of wear and tear. You just need to clean the focus lens periodically to keep up with its performance. In addition to that, you should refrain from using it for longer periods to avoid overheating.

Fiber Laser

If you tried experiments in school and came across the idea of using a lens and sunlight to start a fire, fiber lasers almost work the same. The lens intensifies the power of sunlight and narrows it down, making it so powerful that it can turn into heat and start a fire.

Fiber lasers use an optical fiber cable made of silica glass that guides the laser more intensely and precisely. This narrowed-down laser beam provides more accuracy, allowing it to work more efficiently in sensitive and small spaces.

The initial cost of a fiber laser machine is high, but it makes up for its price with high performance and ease of access. It has low operating costs that require little or no maintenance and uses up a small amount of electricity to work.

We would recommend a 50 Watt Fiber Laser Engraver for engraving gold. For detailed information on the best options then check out our buying guide: Best Fiber Laser Engraver for You

The fiber laser was invented by Elias Snitzer in 1961, and a demonstration of it was displayed to the public in 1963. It wasn’t until the late 1990s that fiber lasers were applied in commercial applications.

You can also check out a detailed article explaining how fiber laser engraving works

Types of Fiber Laser

Fiber lasers can be categorized based on four factors.

Source of Laser

The source of the laser can affect its wavelength. These lasers are doped with different rare-earth materials like:

- Erbium

- Ytterbium

- Neodymium

- Dysprosium

- Praseodymium

- Thulium

- Holmium

The doping of fiber lasers with these materials increases their optical gain and makes them extremely powerful. All these doped fiber lasers have different wavelengths used for different applications.

Operation Mode

You can customize how your laser is released to best suit your needs. There are two operation methods: pulsed fiber lasers and continuous-wave fiber lasers.

Pulsed fiber lasers operate in predetermined repetitions to achieve maximum power and accuracy. It works best on items such as gold, where the substance is highly reflective and requires more density for better precision.

This works best in situations where you have highly customized tasks and different power settings are required at different positions. On the other hand, continuous-wave fiber lasers will send the laser with the same amount of energy without any intervals. Operation is straightforward with a power switch.

Power of Laser

The power of the laser is calculated in watts. These can be at different levels, and higher wattages will have more power. You can select the power of your laser according to the nature of your task and the type of material you want to engrave.

Size of Laser

The thickness of a laser is a significant factor. It varies according to the size of the core. The “core” of a fiber laser refers to the medium through which this laser travels. These are available in two types: single-mode fiber lasers and multi-mode fiber lasers.

Single-mode fiber lasers have a core diameter of eight to nine micrometers, providing a narrowed light that allows them to work more efficiently and with better precision. It is best suited to work on narrow areas with microdetails.

On the other hand, multi-mode fiber lasers have a core diameter of fifty to one hundred micrometers and are suitable for a few less complex tasks.

Final Thoughts

Engraving something can be a great idea to personalize your items and make them more unique. When it comes to engraving expensive things like gold, be cautious and think twice before making a move.

Before engraving your gold items, you have probably asked yourself, “Can you laser engrave gold?” As laser engraving is the most successful and error-free method, it’s a great method to use as long as it’s a fiber laser. It’s recommended that you do your research before engraving your gold items.