UV laser engraving is revolutionizing the way we mark and personalize products across a wide range of industries. Unlike CO₂ or fiber lasers, UV lasers use short-wavelength ultraviolet light to achieve ultra-fine, non-contact, low-heat marking. This precision and versatility make UV lasers ideal for delicate materials and highly detailed engravings.

In this complete guide, we’ll break down how UV laser engraving works, what materials it’s best for, key benefits, and what to look for when buying a UV laser machine.

Table of Contents

What Is UV Laser Engraving?

UV (ultraviolet) laser engraving uses a 355nm wavelength laser—a much shorter wavelength than fiber (1064nm) or CO₂ lasers (10.6μm). This shorter wavelength produces what’s known as “cold light,” which minimizes heat-affected zones and allows for high-precision marking without damaging or melting the material.

UV lasers are a form of solid-state laser that use frequency tripling (3X) to convert infrared light to ultraviolet. This makes them ideal for intricate, high-contrast, and ultra-fine engraving on a broad range of materials.

Why UV Lasers Are Unique

UV lasers operate using a process called “cold marking,” which produces minimal heat-affected zones (HAZ). This ensures:

- No burning or melting

- No structural damage

- High-resolution, high-contrast marks

This makes UV lasers ideal for micro-engraving, plastics, and heat-sensitive materials.

What Materials Can UV Lasers Engrave?

Plastics

UV lasers are particularly well-suited for marking most types of plastic because they won’t warp, melt, or burn the surface like fiber or CO₂ lasers.

Common plastic types UV lasers can engrave:

- ABS – for electronics, housings

- Polycarbonate (PC) – used in firearm components, lenses

- Polyamide (PA or Nylon) – durable, used in automotive and tools

- PET / PETG – common in packaging and ID cards

- POM (Delrin®) – engineering-grade thermoplastic

- Polypropylene (PP) – used in medical and food containers

- PE (Polyethylene) – including foam PE and HDPE

- PVC – UV lasers can engrave it safely (unlike CO₂)

- PES film – transparent film used in electronics and overlays

- Polyimide (PI) – great for circuit boards and flexible electronics

Applications:

Barcodes, logos, product labels, medical instruments, and consumer electronics.

Metals

Although fiber lasers are the industry standard for metal, UV lasers can mark many metals, especially coated or sensitive parts.

Metals UV lasers can mark:

- Aluminum (especially anodized)

- Stainless steel

- Brass

- Titanium

- Gold, Silver, Platinum (for fine jewelry)

- Nickel & Chrome-plated materials

Important: UV lasers are better for surface-level marking, not deep engraving. They are ideal for high-precision text, serials, and decorative logos.

Glass and Crystal

One of the biggest strengths of UV lasers is their ability to engrave glass without cracking.

Applications:

- Custom drinkware (wine glasses, tumblers)

- Awards and trophies

- Smartphone screens

- Optical components

Why UV lasers are best for glass:

They produce no thermal stress—so no chipping or spider cracking, and no need for coating or masking.

Ceramics and Stone

UV lasers can engrave some light ceramic surfaces and delicate stones like marble or tiles.

Applications:

- Electrical insulators

- Ceramic knives and tools

- Decorative tiles

Note: The engraving is often surface-level and not as deep as with CO₂ or fiber lasers.

PCBs and Electronic Components

UV lasers can precisely engrave printed circuit boards (PCBs) and other electronics.

Benefits:

- Doesn’t damage internal circuitry

- Perfect for micro-text, QR codes, and UID marking

- Can mark flexible PCBs and polyimide tapes

Cardboard and Paperboard

UV lasers can lightly engrave or cut thin paper-based products without burning.

Applications:

- Security labels

- Packaging prototypes

- Custom stationery and cards

What UV Lasers Should NOT Engrave

While UV lasers are versatile, there are limitations:

- Thick wood or acrylic: Use a CO₂ laser instead

- Uncoated, raw metals (for deep engraving): Use a fiber laser

- Thick foams or fabrics: Can discolor or fray

Quick Reference Table

Material | Engraving Type | Precision | Notes |

|---|---|---|---|

ABS / Plastic Housing | High-contrast surface marking | ⭐⭐⭐⭐⭐ | No melting or discoloration |

Polycarbonate (PC) | Text, logos, micro text | ⭐⭐⭐⭐ | UV is safer than CO₂ for PC |

Anodized Aluminum | Clean marking | ⭐⭐⭐⭐⭐ | Crisp white-on-black contrast |

Stainless Steel | Light surface marking | ⭐⭐⭐ | Best with blackening effect, not deep |

Glass | Frosted look, no cracks | ⭐⭐⭐⭐⭐ | Perfect for awards and custom gifts |

PCB / Polyimide | Precision UID / QR codes | ⭐⭐⭐⭐⭐ | Electronics safe, no heat damage |

PET / PP / PE | Labeling | ⭐⭐⭐⭐ | Used in bottles, packaging |

Brass / Gold / Silver | Logos, jewelry customization | ⭐⭐⭐⭐ | Fine detail without scratching |

Ceramic | Surface logos and text | ⭐⭐⭐ | Smooth finishes only |

Advantages of UV Laser Engraving

Cold Marking Process

- Prevents material deformation, burns, or melting

- Essential for plastics, glass, and sensitive electronics

High Precision & Detail

- Excellent for QR codes, micro text, and fine graphics

- Achieves resolutions up to 2400+ DPI

Versatility

- Works on a broader range of materials than CO₂ or fiber alone

- Perfect for niche markets like jewelry, medical tools, and PCB manufacturing

Minimal Post-Processing

- Clean marks reduce the need for wiping, sanding, or cleaning

Limitations of UV Lasers

- Higher cost than CO₂ or fiber lasers

- Lower wattage (3W–10W) means it’s not ideal for deep engraving or cutting

- Slower engraving speeds for some materials

- Requires eye protection due to the UV wavelength

Applications of UV Laser Engraving

UV lasers are used in:

- Medical tools & devices (permanent, sterile marking)

- Electronics and circuit boards (non-invasive labeling)

- Cosmetic and personal care packaging (on soft plastics)

- Jewelry and watchmaking (ultra-fine detailing)

- Custom gifts & promotional products (glassware, pens, etc.)

- Firearms and tactical gear (polymer frame engraving)

What To Look For in a UV Laser Engraving Machine

When shopping for a UV laser engraver, consider:

Feature | Importance |

|---|---|

Laser Power | 3W for marking, 5 – 10W for broader capability |

Focusing System | Electric Z-axis/lifting column is ideal |

Software Compatibility | EZCAD and LightBurn preferred |

Rotary Option | For engraving on cylindrical items |

Cooling Method | Air-cooled is best for low-maintenance use |

Precision Level | Look for engraving accuracy around 0.0019mm |

Recommended Budget UV Laser Engraver

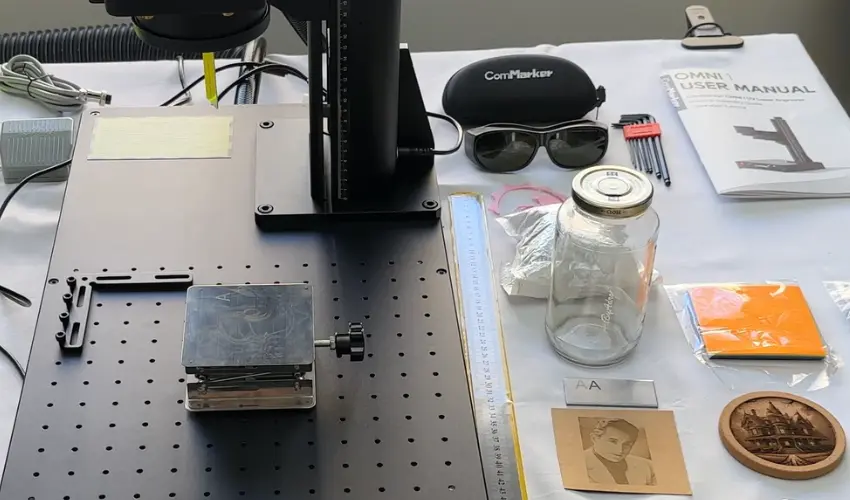

ComMarker 5W or 10W Omni 1 UV Laser Engraver

If you’re looking for an affordable UV laser engraver that delivers industrial-level precision and versatility without the industrial-level price tag, the Omni1 5W UV Laser Engraving Machine is your best bet. Designed by ComMarker, this compact yet powerful device blends ease of use with high-end capabilities—making it a great fit for both small businesses and advanced hobbyists.

Why It’s the Best Budget UV Laser Engraver

UV laser engravers are often expensive, but ComMarker’s Omni1 5W breaks that trend by offering excellent features at a budget-friendly price point. You get exceptional engraving accuracy (0.0019mm), support for both EZCAD and LightBurn software, and the ability to work on virtually any material—from plastics and metals to glass and leather.

Key Features

- Laser Wavelength: 355nm UV cold light laser

- Power Output: 5W (with 10W option available)

- Marking Speed: 0–10,000 mm/s

- Engraving Accuracy: 0.0019mm

- Motherboard: BJJCZ with EZCAD 2 & LightBurn compatibility

- Auto-Focus: Electric lifting column with one-touch operation

- Positioning System: Dual red-light for high-precision targeting

- Weight: Only 23.5 kg – lightweight and portable

- Cooling System: Air-cooled (no need for water chillers)

Pros

- Exceptional Material Compatibility

Engraves plastics (ABS, PET, PC, PVC), metals (aluminum, brass, stainless steel), wood, cloth, leather, glass, ceramics, and even cardboard—making it more versatile than fiber or CO₂ lasers alone. - Electric Lifting + Dual Lenses

Comes with both 70mm x 70mm and 150mm x 150mm lenses for flexible working areas. The motorized Z-axis simplifies focusing for beginners. - Plug-and-Play with LightBurn & EZCAD

Rare for UV engravers at this price to support both industry-standard software platforms. - Cold Light Technology = Minimal Heat Damage

Perfect for engraving sensitive materials with crisp, burn-free details—ideal for electronics, jewelry, and medical components. - Compact Design

Small footprint and 23.5kg weight make it easy to fit into most workshops or home studios. - Batch Marking & QR/Barcode Auto-Generation

A powerful feature for small business owners who need repeatable results on product lines or serial numbers.

Cons

- 5W May Not Be Enough for Deep Engraving

While perfect for surface marking, the 5W version is less suitable for heavy-duty deep engraving. You may consider the 10W version if you need more power. - No Built-In Fume Extraction

Like many budget models, you’ll need an external fume extractor for safe indoor use. - Learning Curve for Software

Though it supports LightBurn and EZCAD, beginners may need some time to become familiar with these programs—especially EZCAD.

What’s in the Box?

- Omni1 5W UV Laser Engraving Machine

- 70mm x 70mm lens and 150mm x 150mm lens

- Rotary axis for cylindrical engraving

- Foot switch, goggles, ruler, lifting platform

- Preview & placing helpers

- USB driver with EZCAD software

- Power adapter, data cable, Allen wrench, screws

Final Verdict

The Omni1 5W UV Laser Engraving Machine hits the sweet spot between professional-level performance and affordability. Whether you’re engraving plastics, sensitive materials like glass, or need crisp logos on metal or leather, this UV laser does it all with incredible precision.

For under $4,000 (depending on sales and configurations), it offers more versatility and precision than many CO₂ and diode laser engravers in the same price range.

Rating: 4.8/5

Best For: Makers, small businesses, tech hobbyists, and professionals needing a low-heat, high-precision laser engraver that’s ready to grow with them.

UV Laser vs. Fiber vs. CO₂: Quick Comparison

Feature | UV Laser | Fiber Laser | CO₂ Laser |

|---|---|---|---|

Wavelength | 355 nm | 1064 nm | 10,600 nm |

Best For | Plastics, glass, electronics | Metals | Wood, acrylic, leather |

Heat Impact | Low (cold light) | Medium | High |

Precision | Very High | High | Medium |

Cutting Ability | Low | High (on metals) | High (on non-metals) |

Price | Higher | Medium–High | Low–Medium |

What is the difference between IR and UV Laser Engravers

The main difference between infrared (IR) and ultraviolet (UV) lasers comes down to wavelength—and that affects what materials they work best with and how they’re used.

In simple terms:

- Infrared lasers have longer wavelengths and are great for engraving metals and hard plastics.

- UV lasers have shorter wavelengths and are better for fine, detailed work on lots of different materials—with almost no heat involved.

Why UV Lasers Are So Precise

UV lasers send out small, highly focused bursts of energy. This lets them remove tiny amounts of material very accurately, almost at the molecular level, without heating or damaging the area around it. That’s a big deal when you’re working on heat-sensitive materials like leather, plastic, or microchips.

Frequently Asked Questions

What is a UV laser engraver, and how is it different from CO₂ or fiber lasers?

A UV laser engraver uses a short-wavelength ultraviolet laser (typically 355nm) to mark or engrave materials using a “cold marking” process, which minimizes heat damage. This sets it apart from CO₂ (10.6μm) and fiber lasers (1064nm), which generate more heat. UV lasers are ideal for heat-sensitive materials like plastics, glass, and electronics, whereas CO₂ is best for organics (wood, acrylic) and fiber for metals.

What materials can UV lasers engrave or mark?

UV lasers can engrave an incredibly wide range of materials with high precision. Common materials include:

Plastics: ABS, PET, PC, POM, PVC, PP, Nylon

Metals: Aluminum, stainless steel, titanium, gold, silver (light surface marking)

Non-metals: Glass, ceramic, paper, wood, leather, fabric

Electronics: Polyimide (PI), circuit boards, microchips

Their ability to engrave with almost no thermal distortion makes them ideal for medical devices, ID cards, and electronics.

Is a UV laser safe to use indoors?

Yes, UV lasers are safe to use indoors when proper safety measures are followed. Always:

Use protective laser safety goggles rated for 355nm UV light.

Keep the laser in a shielded enclosure if possible.

Ensure proper ventilation or fume extraction, especially when engraving plastics that may release fumes.

Follow your machine’s user manual and safety certifications (like FDA or CE).

Can a UV laser engrave metal deeply like a fiber laser?

No, UV lasers are generally not used for deep engraving on metal. They are excellent for high-precision surface marking on metals like aluminum, stainless steel, and brass, especially for:

Serial numbers

QR codes

Logos

Fine decorative detail

For deep metal engraving or cutting, a fiber laser (especially MOPA) is more suitable.

Who should consider buying a UV laser engraver?

UV laser engravers are perfect for:

Small business owners who engrave jewelry, electronics, or ID cards

Industrial users needing precise, non-damaging marks on sensitive parts

Makers & hobbyists looking to mark diverse materials with a compact machine

Tactical/custom firearm engravers needing to mark polymer or coated components

If you work with a variety of materials—especially heat-sensitive ones—and need extreme precision, a UV laser is a smart investment.

Final Thoughts: Is a UV Laser Engraver Right for You?

If you need high-precision, low-impact engraving on plastics, glass, coated metals, or electronics, a UV laser is an excellent investment. While the initial cost may be higher than fiber or CO₂ systems, the versatility, detail, and clean results more than justify the price—especially for professionals in medical, electronics, or product branding industries.

Whether you’re a hobbyist upgrading your shop or a business looking for scalable marking solutions, UV laser engraving opens up a world of possibilities.