Fiber Laser Engraving is used to create permanent marks on metals and some industrial plastics. In the engraving process with a Fiber Laser Engraver, a focussed beam of light is supplied through a fiber optic cable and utilized to engrave the surface of the material.

So exactly how does fiber laser engraving work? Well, if you have ever used a lens to start a fire, you probably know that the lens focuses light from the sun and turns it into heat that can cause combustion. Similarly, a fiber laser engraver pumps intense light at the end of the fiber optic cables which then gives a powerful laser beam. This light beam is then used to engrave patterns on different materials.

Read on to find out what a fiber laser engraver can do, what materials are compatible, and how to choose between a Fiber Laser Engraver and a CO2 Laser Engraver.

Table of Contents

What Can A Fiber Laser Engraver Do?

Fiber laser engravers are well-known for their ability to mark a variety of materials, from metals to industrial plastics, fast and easily. With high-grade industrial fiber laser markers, you may create serial numbers, bar codes, 2D Data Matrix, artwork, and personalization.

A fiber laser has a variety of applications. In fact, most people who buy fiber laser engravers buy them with one use in mind but then eventually branch out into different applications.

Applications of Fiber Laser Engraving

- Manufacturing: Used for marking parts with serial numbers, barcodes, and logos for traceability and branding.

- Jewelry: Engraving intricate designs, names, and dates on rings, bracelets, and other jewelry items.

- Electronics: Marking circuit boards, electronic components, and devices with identification codes and branding.

- Medical Devices: Creating precise markings on surgical instruments and medical implants.

- Automotive: Marking parts and components with detailed information for identification and quality control.

- Gifts and Personalization: Customizing items like trophies, plaques, and personalized gifts with unique engravings.

Let’s have a look at some of the most popular applications in more detail:

- Serializing and barcoding

Engraving barcodes and serial numbers directly onto tools and parts is one of the common uses for fiber lasers. Fiber lasers provide high-quality marks which can be read by a barcode scanner. You can use a variety of code structures for serializing including UPC codes, one-dimensional codes, and data matrix codes.

When serializing several parts, you can use the laser engraver with a jig for holding the various parts on the laser bed and then simultaneously serializing them. This eliminates the need for a dedicated operator for switching out of parts.

- Placing logos on products

If you have a company that is producing high-end products, etching your company logo can help ensure your brand will always be visible to the customer. Laser-engraved logos are better than printed labels because the labels can be removed voluntarily and involuntarily by the customer.

- Making custom products

Customizing products is another popular use for fiber laser engravers. You can run a very successful business as a laser engraver specializing in custom items. On the industrial level, you can help companies and startups to engrave their logos on their products. Alternatively, you can offer to engrave custom products like wall hangings, jewelry, watches, etc.

You can also cut some thin metals with a 50W Fiber Laser, more information can be found on this link.

How Does A Fiber Laser Engraver Work?

Fiber laser engravers are advanced tools used to etch precise, high-quality designs onto various materials, including metals, plastics, and ceramics. Their speed, precision, and versatility make them popular in industries such as manufacturing, jewelry, and electronics. We’ll explore how fiber laser engravers work, including their components, operation, and applications.

Components of a Fiber Laser Engraver

- Laser Source: The heart of the fiber laser engraver is the laser source, which generates the laser beam. This source typically uses a fiber optic cable doped with rare earth elements like ytterbium.

- Pump Diode: This component supplies the energy needed to excite the rare earth elements in the fiber, causing them to emit photons and create the laser beam.

- Optical Fiber: A flexible, thin fiber that guides the laser beam from the source to the focusing lens. It provides high beam quality and energy efficiency.

- Focusing Lens: This lens concentrates the laser beam to a fine point, allowing for precise engraving.

- Galvanometer Scanner: A system of mirrors controlled by a computer that directs the laser beam over the material’s surface according to the design.

- Cooling System: Keeps the laser engraver at optimal operating temperature, preventing overheating and maintaining performance.

- Control System: A computer or dedicated controller that manages the operation of the engraver, including the design input, laser power, speed, and other parameters.

How Fiber Laser Engraving Works

- Design Input: The process begins with a digital design created using graphic design software such as Adobe Illustrator, CorelDRAW, or CAD programs. The design is then converted into a format that the laser engraver can interpret, typically a vector file or a raster image.

- Beam Generation: When the engraver is activated, the pump diode energizes the rare earth elements in the optical fiber. This excitation causes the elements to emit photons, which are then amplified as they travel through the fiber, creating a coherent laser beam.

- Beam Delivery: The laser beam travels through the optical fiber to the focusing lens. The flexibility and precision of the fiber allow for efficient and accurate delivery of the beam to the work area.

- Focusing: The focusing lens concentrates the laser beam to a very fine point, typically a few micrometers in diameter. This focused beam has high energy density, which is crucial for engraving.

- Engraving: The galvanometer scanner, controlled by the computer, directs the focused laser beam across the surface of the material according to the design. The high energy of the laser beam interacts with the material, vaporizing or ablating it to create the engraved pattern.

- Cooling and Monitoring: Throughout the process, the cooling system ensures that the laser engraver maintains a stable temperature, preventing damage to the components and ensuring consistent performance. The control system monitors the process, making real-time adjustments as necessary to achieve the desired result.

Key Features of Fiber Laser Engravers

- High Precision: The fine focus of the laser beam allows for extremely detailed and precise engravings, suitable for intricate designs and small text.

- Speed: Fiber lasers can engrave at high speeds, making them efficient for both single-piece and mass production.

- Durability: The components, especially the optical fiber, are robust and have a long lifespan, requiring minimal maintenance.

- Versatility: Fiber laser engravers can work with a wide range of materials, including metals (steel, aluminum, gold), plastics, ceramics, and more.

- Energy Efficiency: They convert a high percentage of electrical energy into laser light, making them more energy-efficient compared to other types of lasers.

Advantages of Fiber Laser Engraving

- Non-Contact Process: The laser beam doesn’t physically touch the material, reducing wear and tear on the engraver and avoiding damage to the material.

- High-Quality Results: Produces clean, permanent engravings with high contrast and detail.

- Minimal Waste: Laser engraving is precise and efficient, producing minimal waste material.

- Automation: Easily integrated into automated systems for high-volume production with consistent quality.

Which materials are compatible with fiber laser engraving?

Not every material is a good match for fiber laser engraving. For instance, most transparent materials will not work with fiber laser engraving techniques. Instead of engraving them, the beam passes through and engraves the table. You can still work with plastics but must look for ones with some pigmentation and not transparent ones.

Additionally, organic materials are not well suited for fiber laser engraving. Wood, clear glass, leather, clear acrylic, and other fabrics are also transparent to the 1064nm wavelength and would therefore not be ideal for fiber laser engraving. But they can still be engraved – you just need to find the right engraver.

The following is a list of materials that are commonly used with fiber laser engravers:

- Aluminum

- Brass

- Carbide

- Carbon fiber

- Carbon Steel

- Chrome

- Coated Metals

- Copper

- Fiberglass

- Gold

- Inconel Metals

- Metal Plated Ceramics

- Magnesium

- Molybdenum

- Nickel

- Non-Semiconductor Ceramics

- Nylon

- Plastics & Polymers: Such as ABS, Nylon, Delrin, Polypropylene and Polyethylene

- Rubber

- Silver

- Stainless Steel

- Synthetic Leather

- Titanium

- Tungsten

How to use a Fiber Laser Engraver on Non-Compatible Materials

Even though not every material is ideal for fiber laser engraving, you can still pull it off with a couple of hacks. Here are some hacks worth trying.

- To enhance a mark, use oxidizers, foils and paint fills.

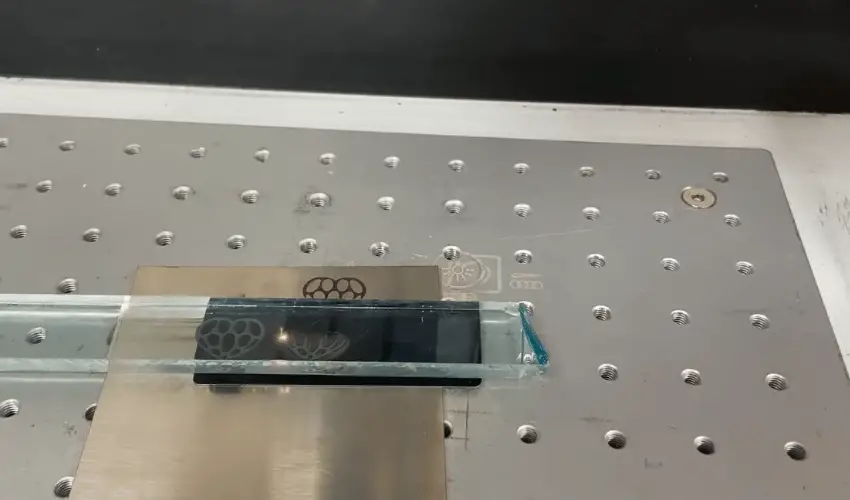

- If you place a metal plate under a transparent material, you will get a mark on it. This is because the fiber wavelength passes through the material and marks the metal plate and then reflects the beam right back to the bottom side of the transparent material.

- Use a marker to temporarily color a transparent polymer and then do the engraving. You can then use a cleaning agent to remove the coloring and you should have your nicely engraved transparent material.

- Alternatively, just use an alternative material that is compatible with fiber laser engravers

Types of marks that can be made on a surface with a fiber laser engraver

Fiber laser engravers are versatile tools capable of creating a variety of marks on different materials. Depending on the application and desired outcome, you can achieve different types of marks by adjusting the laser settings and techniques. Here are the main types of marks that can be made with a fiber laser engraver:

1. Engraving

Description: Engraving involves removing material to create a deep, permanent mark. This method is commonly used for detailed designs, text, and logos.

Applications:

- Jewelry: Engraving names, dates, and intricate designs.

- Tools and Equipment: Marking serial numbers, barcodes, and branding.

- Trophies and Awards: Creating personalized messages and designs.

Process:

- Laser Settings: High power and low speed to ensure deep penetration.

- Material Removal: The laser beam vaporizes or ablates the material to create a recessed mark.

2. Etching

Description: Etching creates a shallow mark on the surface without significant material removal. It’s ideal for adding fine details and surface-level designs.

Applications:

- Electronics: Marking circuit boards and electronic components.

- Automotive Parts: Adding identification marks and logos.

- Promotional Items: Customizing pens, keychains, and other items.

Process:

- Laser Settings: Medium power and medium speed to control depth.

- Surface Interaction: The laser slightly alters the material’s surface to produce a subtle, visible mark.

3. Annealing

Description: Annealing is a process that heats the material to create an oxidation layer on the surface without removing any material. This method is often used on metals to produce high-contrast, smooth marks.

Applications:

- Medical Instruments: Marking surgical tools with high-contrast, corrosion-resistant marks.

- Metal Products: Adding logos and branding to stainless steel and titanium items.

Process:

- Laser Settings: Low power and slow speed to generate enough heat.

- Color Change: The heat causes oxidation, changing the color of the surface to create the mark.

4. Foaming

Description: Foaming is a technique where the laser creates small gas bubbles within the material, raising the surface slightly and producing a frosted appearance.

Applications:

- Plastics: Marking items like buttons, covers, and housings.

- Consumer Goods: Adding decorative elements to plastic products.

Process:

- Laser Settings: Adjust power and speed to control bubble formation.

- Surface Reaction: The laser heats the material, creating gas bubbles that cause a frosted, raised mark.

5. Color Marking

Description: Color marking is possible on some metals and plastics, where the laser alters the surface to produce different colors. This technique is often used for decorative purposes and detailed designs.

Applications:

- Decorative Items: Adding multicolored designs to metal jewelry and accessories.

- Consumer Electronics: Marking logos and graphics on devices.

Process:

- Laser Settings: Fine-tuned power and speed settings, along with specific wavelengths, to achieve color changes.

- Material Interaction: The laser affects the material’s surface structure or oxide layer to produce colors.

6. Surface Ablation

Description: Surface ablation involves removing a thin layer of material to expose a different underlying layer or to clean the surface.

Applications:

- Painted Metals: Removing paint to reveal bare metal beneath for contrast.

- Anodized Aluminum: Removing the anodized layer to create high-contrast marks.

Process:

- Laser Settings: High power with controlled speed to precisely remove the top layer.

- Layer Removal: The laser ablates the top layer, exposing the underlying material or cleaning the surface.

7. Deep Engraving

Description: Deep engraving is a more intense form of engraving, where a significant amount of material is removed to create a deep, pronounced mark. This method is used for applications requiring durable, long-lasting marks.

Applications:

- Molds and Dies: Creating detailed, deep engravings for industrial use.

- Heavy-Duty Equipment: Marking parts and components that undergo heavy wear.

Process:

- Laser Settings: Very high power and low speed, possibly multiple passes.

- Material Removal: The laser makes deep cuts into the material, creating a substantial recess.

How to engrave with a Fiber Laser Engraving Machine

Fiber laser engraving machines are powerful tools that can create precise and detailed designs on various materials, such as metals, plastics, and ceramics. Whether you’re new to laser engraving or looking to improve your technique, this guide will walk you through the process step-by-step to help you achieve the best results.

Step 1: Choose the Right Machine

Before starting, ensure you have the right fiber laser engraving machine for your needs. Key factors to consider include:

- Power Output: Higher wattage machines can engrave deeper and faster but may be overkill for lighter tasks.

- Work Area Size: Ensure the machine’s work area is large enough for your projects.

- Software Compatibility: Check that the machine is compatible with your design software.

Step 2: Prepare Your Design

Creating a high-quality design is crucial for successful engraving. Here’s how to prepare your design:

- Select Design Software: Use graphic design software like Adobe Illustrator, CorelDRAW, or AutoCAD for creating vector designs. For bitmap images, software like Photoshop or GIMP can be used.

- Create or Import Design: Start from scratch or import an existing design. Ensure your design is high-resolution for the best engraving results.

- Convert to Compatible Format: Save your design in a format compatible with your laser engraver, such as SVG, DXF, or AI for vector images, and PNG or BMP for bitmap images.

Step 3: Set Up the Engraving Machine

Proper setup of the machine is essential for accurate engraving. Follow these steps:

- Turn on the Machine: Power up your fiber laser engraver and allow it to initialize.

- Load the Design: Transfer your design file to the machine using a USB drive, direct connection, or network transfer.

- Position the Material: Place the material you want to engrave onto the work area. Ensure it is securely positioned to prevent movement during engraving.

Step 4: Configure Machine Settings

Adjust the machine settings according to your material and design requirements:

- Select Material Type: Choose the appropriate material setting on your laser engraver. This will adjust the default power and speed settings.

- Adjust Laser Power and Speed: Fine-tune the power (laser intensity) and speed (movement of the laser head) settings to suit your material and desired depth of engraving. For example, metals typically require higher power and slower speeds than plastics.

- Set Focus: Ensure the laser is properly focused on the material. This may involve adjusting the height of the laser head or using an auto-focus feature if available.

- Test Run: Perform a test run on a scrap piece of the same material to ensure settings are correct and make any necessary adjustments.

Step 5: Start Engraving

With everything set up and tested, you’re ready to start engraving:

- Initiate Engraving: Start the engraving process through the machine’s control panel or connected computer.

- Monitor the Process: Keep an eye on the engraving process to ensure everything is running smoothly. Be ready to pause or stop the machine if any issues arise, such as material shifting or unexpected laser behavior.

- Safety Precautions: Always wear appropriate safety gear, including safety goggles, and ensure good ventilation to avoid inhaling any fumes generated during engraving.

Our Buying Guides Can Be Found Here:

1. Top 5 Laser Engraver Exhaust Fan Options: Best Quality!

2. Best Fume Extractors for Laser Engravers: 5 Quality Options!

3. Laser Engraver Enclosure Options: You Need The Best Quality

4. Laser Engraving Eye Protection – Most Important Information

Step 6: Post-Engraving Steps

After the engraving is complete, follow these steps to finalize your project:

- Inspect the Engraving: Check the quality of the engraving to ensure it meets your expectations. Look for any areas that might need touch-ups or additional passes.

- Clean the Material: Remove any residue or debris from the engraved area. Use a soft brush or cloth, and if necessary, a mild cleaning solution that won’t damage the material.

- Make Adjustments if Needed: If the engraving is not as deep or clear as desired, adjust the settings and run another pass. Alternatively, make adjustments to the design or machine settings based on the initial results.

Tips for Successful Engraving

- Material Compatibility: Ensure the material you are engraving is suitable for fiber laser engraving. Metals, certain plastics, and ceramics are generally compatible, while materials like PVC can release harmful fumes and should be avoided.

- Maintain Your Machine: Regular maintenance of your fiber laser engraver, such as cleaning the lens, can improve performance and longevity.

- Experiment with Settings: Different materials and designs may require different settings. Experiment with power, speed, and focus to find the optimal combination for each project.

- Software Proficiency: Becoming proficient in your design software can help you create more detailed and intricate designs, enhancing the quality of your engravings.

How to Choose Between A Fiber Laser Engraver and A CO2 Laser Engraver?

Laser engraving and cutting technologies have revolutionized various industries, from manufacturing to art and design. Among the most commonly used types are fiber lasers and CO2 lasers. While both have their strengths, they differ significantly in terms of technology, applications, and performance. This guide provides a detailed comparison between fiber lasers and CO2 lasers to help you understand which might be best suited for your needs.

Technology and Operation

Fiber Lasers

Fiber lasers use a solid-state technology where the laser beam is generated by a series of diodes and amplified in a specialized optical fiber doped with rare-earth elements like ytterbium. The beam is delivered through a flexible fiber optic cable to the cutting or engraving head.

Key Features:

- Wavelength: Typically around 1064 nm.

- Efficiency: High electrical-to-optical efficiency, often exceeding 30%.

- Beam Quality: Excellent beam quality with high intensity and focusability.

CO2 Lasers

CO2 lasers use a gas mixture primarily composed of carbon dioxide, nitrogen, and helium to produce the laser beam. The beam is generated in a gas-filled tube and then directed to the cutting or engraving head using mirrors.

Key Features:

- Wavelength: Typically around 10.6 µm.

- Efficiency: Lower than fiber lasers, usually around 10-20%.

- Beam Quality: Good beam quality but less focusable than fiber lasers.

Applications

Fiber Lasers

Fiber lasers are highly effective for:

- Metal Engraving and Cutting: Ideal for steel, aluminum, brass, and other metals.

- Marking: Perfect for high-contrast, permanent marks on metals and some plastics.

- Electronics and Automotive: Widely used for precision marking and micro-machining components.

CO2 Lasers

CO2 lasers excel in:

- Non-Metal Materials: Excellent for cutting and engraving wood, acrylic, leather, and textiles.

- Organic Materials: Suitable for materials like paper, cardboard, and rubber.

- Large-Scale Applications: Often used in large-format cutting for signs and architectural models.

Performance and Precision

Fiber Lasers

- Speed: Generally faster than CO2 lasers, especially on metals.

- Precision: Higher precision due to a smaller focal diameter and better beam quality.

- Depth of Engraving: Capable of deeper engraving on metals.

CO2 Lasers

- Speed: Effective on non-metals but generally slower than fiber lasers on metals.

- Precision: Good for detailed work on non-metals but less precise on metals compared to fiber lasers.

- Versatility: More versatile in handling a wide variety of non-metal materials.

Cost and Maintenance

Fiber Lasers

- Initial Cost: Higher upfront cost due to advanced technology.

- Maintenance: Low maintenance with longer operational life and fewer consumables.

- Operating Cost: Lower operating costs due to higher efficiency and less frequent need for replacement parts.

CO2 Lasers

- Initial Cost: Generally lower upfront cost.

- Maintenance: Higher maintenance requirements, including regular mirror and lens cleaning, and laser tube refills or replacement.

- Operating Cost: Higher due to lower efficiency and more frequent maintenance needs.

Advantages and Disadvantages

Fiber Lasers

Advantages:

- High efficiency and lower operating costs.

- Superior performance on metals.

- Low maintenance and longer lifespan.

Disadvantages:

- Higher initial investment.

- Limited effectiveness on certain non-metal materials like wood and glass.

CO2 Lasers

Advantages:

- Excellent for a wide range of non-metal materials.

- Lower initial cost.

- Versatile for various applications, including cutting and engraving.

Disadvantages:

- Lower efficiency and higher operating costs.

- More maintenance required.

- Less effective on metals compared to fiber lasers.

Choosing the Right Laser

Consider Your Material:

- For metal-focused applications, fiber lasers are the clear choice due to their efficiency and precision.

- For a variety of non-metal materials, CO2 lasers offer more versatility and lower initial costs.

Consider Your Budget:

- If initial budget constraints are a major factor, CO2 lasers may be more accessible.

- For long-term efficiency and lower operational costs, fiber lasers are more economical.

Consider Your Application:

- For industrial applications requiring high-speed, high-precision metal work, fiber lasers are ideal.

- For arts, crafts, signage, and other non-metal applications, CO2 lasers are highly effective.

Both fiber and CO2 lasers have unique strengths and are suited to different applications. Understanding the specific needs of your projects and materials is crucial in choosing the right laser technology. Fiber lasers offer superior performance for metalwork with higher efficiency and lower maintenance, while CO2 lasers provide versatility and affordability for non-metal materials. By carefully considering your requirements, you can select the laser engraver that best fits your needs and budget.

Frequently Asked Questions

How much does a Fiber Laser Engraving Machine Cost?

The cost of fiber laser engraving machines varies substantially depending on the fiber laser source. We recommend the following Fiber Laser Sources:

- Raycus

- JPT

- Max

Many high-end systems are in the 4000 – 8000 thousand dollars range. While it is feasible to purchase inexpensive fiber laser machines, they are frequently of poor quality and will either not operate well or will not last long. For detailed information on our recommendations it would be helpful to read our fiber laser engraver buying guide here.

Can a Fiber Laser Marker Engrave Glass?

You can engrave on glass surfaces by laying the glass on top of a stainless steel or aluminum plate and marking it with a fiber laser. The fiber laser beam engraves the stainless steel or aluminum plate as it passes through the transparent glass. The engraving from the steel plate leaves an engraved mark on the glass surface. Mirror glass can also be engraved using a fiber laser system by removing only the reflective coating on the back.

Can a Fiber Laser Marker Engrave Wood?

A fiber laser is not recommended to engrave or mark wood. Because of its shorter wavelength, a fiber laser’s 1064nm wavelength only travels partially through the wood which will result in a poor quality mark as well as a high risk of fire. This reaction is induced by variations in the wood substance and as heat builds up the wood will eventually catch fire.

Final Thoughts

Fiber Laser Engravers employ a laser beam to permanently mark or engrave various types of materials. Because they can mark small objects and engrave brand identities, fiber lasers are utilized in a variety of industries, including the jewelry and electronics sectors.

They can be applied to a variety of materials, including industrial plastics, carbon fiber, and metals (steel, aluminum, copper, etc.). Fiber laser marking machines provide some difficulties because they are not the ideal choice for transparent materials and engraving on non-metals like wood and acrylic.

Related Posts: How Deep can a 20W Fiber Laser Engrave Best Fiber Laser Engraver for You: Top 5 What can a 50W Fiber Laser Cut? Important Information Laser Engraving Machine for Metal – Which Is The Best? Maintenance and Care Tips for Your Fiber Laser Engraver