There are many things you can do with lasers, from creating simple shapes to engraving graphics or creating 3D shapes and models, the possibilities are endless. However, there are some items you will require. Aside from the obvious (laser cutter and materials), one more thing you need is a laser cutting file. The file is what guides the laser machine into making the desired cut or engraving design.

So, what kind of file do you need for laser cutting? Well, several options are available. They include:

Vector files - Raster files

- CAD & 3D design files

In this article, we will take a deep look at each file type, various extensions available, and what you can use them for during laser processing.

Table of Contents

Common File Types for Laser Cutting

Vector files

Vector files are images that are made up of mathematical formulas and calculations. They are made up of lines and shapes that can either follow straight or curved paths.

Vector files are like a map that provides a distinct path with lines and coordinates that the laser machine should follow. They are not made up of pixels and thus are not affected by resolution. Therefore, the size of the images can be adjusted infinitely, and they will always appear clear and crisp.

Several vector file formats are available for use when it comes to laser cutting/engraving. They include:

- AI (Adobe Illustrator) – one of the most popular vector file formats used in laser cutting. It is common for cutting shapes and designs, or engraving graphics such as logos. It is used with Adobe Illustrator software.

- SVG (Scalable vector graphics) – it is used to create graphic images that can be size-adjusted while remaining smooth and clean. It can be used with SVG Edit.

- CDR (CorelDraw) – It is used with CorelDraw or other Corel programs.

Why vector files?

- They contain precise path information.

- They allow easy scaling without losing quality.

- They guide the laser exactly where to cut or engrave.

Tips When Using Vector Files for Laser Cutting

1. Use Thin or Hairline Stroke Widths

- Set cutting lines to hairline thickness (typically 0.001 inch or less).

- This signals the laser software to cut rather than engrave or rasterize.

2. Ensure All Shapes Are Closed Paths

- Closed paths are necessary for proper cutting.

- Open lines may cause incomplete cuts or unexpected movements.

3. Convert Text to Outlines or Paths

- Always convert fonts to curves/outlines before saving.

- This prevents font substitution issues if opened on a different system.

4. Color Code Your Layers

- Assign specific colors to different operations:

- Red = Cut

- Blue = Score

- Black = Engrave

- Follow your machine’s color settings for easy operation setup.

5. Simplify Complex Paths

- Clean up unnecessary nodes or anchor points.

- Simplified paths speed up cutting and reduce machine errors.

6. Check Your File Scale and Units

- Confirm that your file uses the correct units (mm or inches) depending on your laser software settings.

- Scale the design to the correct finished size before exporting.

7. Avoid Overlapping Lines

- Duplicate or overlapping lines cause the laser to cut the same area multiple times.

- This can burn edges or waste time—always check and remove duplicates.

8. Save in Compatible Formats

- Preferred file types include SVG, DXF, AI, or EPS.

- Save/export in the file format your laser cutter or software requires (and use older versions if needed for compatibility).

9. Test with a Scrap Cut

- Before doing a final cut on expensive material, run a test cut on scrap to check settings and path behavior.

10. Keep a Backup Copy

- Always save a master file separately in case you need to make adjustments later.

Final Tip:

When in doubt, import your file into the laser software and preview the job. It’s the fastest way to catch mistakes like open paths, wrong colors, or missing outlines!

Raster files

Raster files, also known as bitmap, are graphic images that are made up of pixels. The pixels contain tonal information and unique colors. Together, these pixels add up to create the image you see when displayed on a computer, paper, or other surfaces.

Since raster files are made up of pixels, their clarity is dependent on resolution. If you zoom in on a raster image, you will start seeing tiny squares (the pixels) as the image increases in size. This is the main difference between raster and vector files.

When it comes to raster or bitmap files, several formats are available. They include:

- BMP (Bitmap image file) – Most laser software—including LightBurn, EZCAD, RDWorks, and LaserGRBL—can easily import BMP files for raster engraving workflows.

- JPEG (Joint Photographic Expert Group) – one of the most popular raster image files. However, it tends to compress images, leading to pixel loss.

- GIF (Graphics Interchange Format) – a raster file format that only supports up to 256 colors. Mainly used for creating animation images.

- PNG (Portable Network Graphics) – was designed to replace GIF files in terms of color options (48-bit color options). PNG files also have the added advantage of lossless compression.

- TIFF (Tagged Image File Format) – popular with commercial printing since it supports Photoshop’s program features while creating lossless compression images.

These raster files can be created and edited using various software programs such as Photoshop, Painter, Photo-PAIN, GIMP, Corel Painter, and others just to mention a few.

Why raster files?

- Great for photo engraving or shaded images.

- The laser will engrave the different pixel shades to create depth.

Important Tips When Using BMP Files for Engraving

- Resolution Matters: Use high-resolution images (at least 300 DPI) for the best engraving quality. Low-res BMPs can look pixelated or blurry when engraved.

- Convert to Grayscale: If you’re doing a detailed photo engraving, convert your BMP to grayscale before importing it into your laser software for better tonal control.

- Adjust Image Contrast: Boost contrast and sharpness before engraving to make sure the final engraved image has strong highlights and dark shadows.

- No Vector Cutting: Because BMP files are pixel-based, they cannot be used for cutting paths. If you need to cut, you’ll need to convert it to a vector file like SVG, DXF, or AI. See below for step by step instructions.

Compound files

While vector and raster files are the most popular, some files can store both vector and raster graphics. These include:

- EPS (Encapsulated PostScript) – a graphic file image that can be found on the Adobe Illustrator software. It is mainly used to create 2D vector images, but can also store text and bitmap images.

- PDF (Portable Document Format) – It can either be vector or raster depending on the software program used. For example, Adobe Illustrator or CorelDraw will create vector PDF files. On the other hand, Photoshop and Corel Paintshop will create raster files

CAD & 3D Design files

Another classification of files used in laser cutting or engraving is the CAD (computer-aided design) files. These files are created using CAD software programs such as AutoCAD, FreeCAD, TinerCAD, Fusion 360, Solidworks, DraftSight, and others.

CAD files are vector in nature. However, they differ from other vector files in that they are more technical (as opposed to being graphics). Therefore, they are mainly used to create complex 2D or 3D designs for laser cutting.

Examples of CAD file formats used in laser cutting include:

- DXF (Drawing Exchange Format) – popularly known as AutoCAD DXF, it is a CAD file developed by Autodesk. DXF files are ideal if you are looking to create mechanical parts or metal fabrication projects (laser cut signs, etc.).

- DWG (DRAWING) is a CAD vector file for creating 2D or 3D designs. It is native to the AutoCAD program and thus supports all its features.

Tips When Using DXF Files for Laser Cutting

- Ensure all shapes are closed paths for proper cutting.

- Use hairline or very thin line weights for cutting paths.

- Check for duplicate lines (they can cause double cuts).

- Simplify complex designs if necessary—too many nodes or intricate paths can slow down or confuse the laser cutter.

How do you make a laser cutting file?

The above are the various types of files that you can use for your laser cutting projects. But how do you go about preparing a file that you will load into your laser cutter?

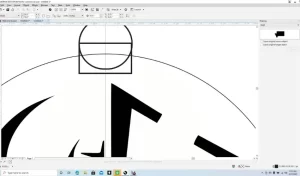

- Choose the file type you want to create and the program to do it. In this example, we will be creating a Vector AI file using Adobe Illustrator.

- Launch the program on your computer and create a new file (File > New).

- Name your document and enter its dimensions. For easier cutting/engraving, let the dimensions match those of the material you are cutting.

- Go to Illustrator’s sidebar and choose the tools you want to use and start drawing the design you want. The tools at your disposal include line, shape, or text tools.

- Next, you need to set the correct stroke width to set the laser path to be followed. For example, most laser cutting machines use a 0.001 stroke for cutting. Anything larger than that will be etched.

- If you want to etch or engrave, you need to set the color and fill for your design. Filling your shape will notify the laser cutter that it should engrave instead of cutting. The fill should be in greyscale (black for deepest engraving level)

- You can also create an etching file by increasing the stroke width of the shape (anything above 0.001pt)

- Once you are done, go through the design to correct any mistakes, then save your file (.ai format).

File Preparation Tips for Laser Cutting

- Outline Your Designs: Make sure all shapes are closed paths.

- Use Hairline or Thin Lines: Most machines recognize hairline-width (0.001 inch) paths for cutting.

- Set Correct Colors: Some lasers differentiate between cut, score, and engrave operations based on color codes (e.g., red = cut, blue = score, black = engrave).

- Convert Text to Curves/Outlines: Fonts can cause issues if not converted to paths.

- Clean Up the File: Remove hidden layers, extra points, and unnecessary elements to avoid unexpected cuts.

- Save in the Correct Version: Some machines require older versions of DXF or AI files for compatibility.

How do you prepare an image for laser engraving?

What if you want to engrave an image? How do you go about preparing it for your laser cutter? Below is a look at how to do it:

- Get the image you want to use – you can download, scan, sketch, or photograph an object.

- Load the image into the editing software you want to use (for example, Photoshop).

- Convert the image into the greyscale mode to remove the color information

- Next, set the greyscale level to determine the strength of the engraving. Dark will have the highest engraving strength, while pale grey will have the least. White color will lead to no engraving.

- If there are any texts in the image, convert them to outlines to create laser paths that can be read.

- Once the image is ready, save it to the desired format (BMP for the best results)

Popular Software for Preparing Laser Cutting Files

- Adobe Illustrator (AI, SVG, PDF, EPS)

- CorelDRAW (CDR, AI, PDF)

- Inkscape (Free; SVG, DXF)

- AutoCAD (DXF, DWG)

- LightBurn (supports a wide variety of vector formats)

Quick Summary

Purpose | Best File Type |

|---|---|

Cutting | Vector files (.SVG, .DXF, .AI, .EPS) |

Engraving (Photos/Images) | Raster files (.JPG, .PNG, .BMP) |

Always double-check the requirements of your laser cutter or service provider before finalizing your file!

How to Convert a Raster File to a Vector File (Step-by-Step)

If you want to laser cut or engrave an image, it usually needs to be converted from a raster file (like JPG or PNG) into a vector file (like SVG or DXF). Here’s how you can do it easily:

1. Choose the Right Software

You’ll need vector editing software. Popular options include:

- Adobe Illustrator (paid, industry standard)

- Inkscape (free and open-source)

- CorelDRAW (paid, popular for lasers)

- LightBurn (laser control software with vector tracing tools)

2. Import Your Image

- Open your chosen software.

- Import or open the raster image (JPG, PNG, BMP, etc.) you want to convert.

3. Trace the Image

You’ll use an auto-trace or image trace feature to create vector paths from the image.

- In Adobe Illustrator:

- Select the image → Click Window > Image Trace → Choose a preset (like “Black and White Logo”) → Click Expand to finalize paths.

- In Inkscape:

- Select the image → Click Path > Trace Bitmap → Adjust settings (like brightness cutoff or edge detection) → Click OK to create a vector version.

- In LightBurn:

- Import the image → Select it → Use Tools > Trace Image → Adjust the threshold → Click OK to create a vector outline.

4. Clean Up the Paths

After tracing:

- Delete unwanted background elements.

- Smooth out nodes if needed (reduce complexity).

- Adjust curves and lines to sharpen or simplify the design.

5. Save or Export the Vector File

Once cleaned up:

- Save or export your design in a laser-compatible vector format, such as:

- .SVG (Scalable Vector Graphics)

- .DXF (Drawing Exchange Format)

- .AI (Adobe Illustrator)

Make sure all text (if any) is converted to outlines/paths before saving.

Quick Tips:

- High-contrast images (like black-and-white logos) trace much better than complex color photos.

- Simplify the design—fewer details make for cleaner, faster laser cuts.

- Test your vector by zooming in — it should stay crisp, not pixelated!

Converting an image to a vector file opens up huge creative possibilities for laser cutting and engraving! It’s easier than you might think with the right tools—and a little practice will make you even faster.

Frequently Asked Questions

What file types are best for laser cutting?

For laser cutting, vector files are best. Common formats include.SVG, .DXF, .AI, .EPS, and properly prepared vector-based PDFs. These files contain precise path information that the laser follows to cut accurately.

Can I use a JPEG or PNG file for laser cutting?

No, JPEG and PNG files are raster (pixel-based) images. They are suitable for engraving (especially photo engraving), but not for cutting, because they don’t contain the vector path data that a laser needs to follow for cuts.

Is a DXF file good for laser cutting?

Yes! DXF files are one of the most widely accepted formats for laser cutting. They are vector-based, widely compatible with different laser software, and ideal for precise mechanical and artistic cutting projects.

What should I check before sending my file for laser cutting?

Make sure that:

All lines are vectors, not pixels.

Shapes are closed paths for cutting.

Text is converted to outlines to avoid font errors.

Layers and colors are properly assigned (e.g., red for cuts, blue for scores, black for engraves, depending on the machine’s setup).

Line thickness is set to hairline or very thin for cut paths.

Can I use a PDF file for laser cutting?

Yes, but only if it is a vector-based PDF. A vector PDF contains paths and curves, which lasers can follow. If the PDF only contains scanned images or embedded bitmaps, it can only be used for engraving, not cutting.

Final Thoughts

Do you have an interest in laser cutting and engraving? The above information can help you to get started. You can now choose the different types of files and programs to create and edit your laser cutting files/images. The several file options can be confusing, but you will be a pro at picking out the best in no time.