Wood is one of the popular materials for laser engraving projects. It exudes a natural feel that fits perfectly with timeless uses and applications. However, the type of wood you use has a huge impact on the outcome of your project. Here’s a guide to help you pick out only the best wood for your laser projects.

Table of Contents

Which is the best wood for laser engraving?

Any wood that is lightweight and has minimal streaking will produce high-quality and attractive engravings.

Some of the best woods for laser engraving include Basswood, Birch, Cherry, Maple, Alder, and Walnut. The wood’s resin content determines whether your engraving will become light or dark.

- Basswood – Soft, smooth, and produces high-contrast engravings.

- Birch – Affordable, fine-grained, and ideal for detailed designs.

- Cherry – Offers rich, dark engravings with a smooth surface.

- Maple – Provides crisp details but requires higher laser power due to its density.

- Alder – Lightweight, engraves well, and produces good contrast.

- Walnut – Darker wood with excellent contrast when engraved.

Woods to Avoid:

- Oak – Has a coarse grain, leading to uneven engravings.

- Pine – Contains resin, which can cause inconsistent burns and charring.

- MDF (Medium-Density Fiberboard) – Can produce excessive fumes due to its glue content.

Factors to consider when choosing the best wood for laser engraving

Wood is revered for being natural and authentic. Whether it is used in furniture, a painting, or a key holder, it carries a feeling of originality. Unfortunately, as a natural material, wood has a ton of inconsistencies that can easily throw your laser projects off. It will take time to master the craft of working with wood but if you stick with it, you will soon get the hang of things.

There are important factors to put into consideration when choosing the best wood for laser engraving:

- Resin content

- Streaking

- Grain and Density

- Color and Contrast

- Pre-Finished or Unfinished Wood

Resin content

Resin is a highly viscous or solid substance that trees give off as a way of protecting themselves from disease and bugs. Resinous wood types typically produce more resin than non-resinous trees. These are primarily softwood species including pine, cedar, and fir. Non-resinous trees are associated with hardwoods such as apple, alder, aspen, ash, elm, birch, madrone, walnut, oak, and locust.

The resin content is important in laser engraving because wood burns light or dark depending on the amount of resin contained in it. When you use wood with high resin content, expect a dark burn. This is because the laser beam will first burn the resin and in turn drive this into the wood.

In the case of low resin content, the laser will vaporize the material causing a minimal burn. If you are looking for a darker burn, choose wood high in resin content. The most common ones include Cherry and Alder. Else, if you desire lighter engravings, go for wood with low resin content.

How do you know if your wood has high or low resin content?

The easiest and most practical way to know the resin content is to do a quick burn test on your wood plaque. Simply engrave the logo of your brand at the back of your material (or anywhere that won’t affect the customization of the wood).

In doing so, you can tell first-hand if the engraving will be dark or light. This process will also help you push your brand further. Talk about killing two birds with one stone!

Another trick to know if the wood plaque has high or low resin content is to eyeball it and compare it with the actual color of the wood species. If it is lighter, it shows the wood has low resin content.

If it is darker, it indicated high resin content. This technique can only be accurate if you’ve been in the industry for quite some time. If you are a beginner, stick to option 1.

Lighter wood creates better contrast

To be honest, lighter wood guarantees clearer and appealing engravings. With wood, the base of the laser engraved product doesn’t change as is the case with other materials like paper. This means you cannot really manipulate it to suit your needs. The base color of the engraved product will have the same color as the original color of the wood.

With this in mind, darker wood obscures your laser marks making it hard to read the text or designs of the product. Lighter wood, on the other hand, produces a deep dark burn that contrasts perfectly with the surrounding material. But eventually, your preferences and needs will determine the choice of wood to use.

Note: sometimes you may end up with varied engravings despite using the same wood and laser engraving settings. This could mean that the tree was harvested during fall or winter. Biologically, trees drop their resins towards the bottom of their trunks in preparation for cold weather ahead. Once the cold is passed, the resin goes back up.

Streaking

Wood has natural lines that refer to the way the wood-cell fibers are oriented. These can be straight, interlocked, diagonal, irregular, wavy, or twisted. Regardless of the shape of the lines, go for wood that has some form of consistency. This masks the streaks to a greater extent.

Streaks are a no-no when it comes to laser engraving. This is because of the simple reason that they steal the attention of the engraving. When you look at engraved wood, your eyes will be drawn to the streaks rather than the actual engraving. Apart from the resin content, you want to use wood that has minimal streaking and a smooth consistent grain.

Wood Grain and Density

The grain pattern and density of wood affect the engraving process. Woods with a uniform, fine grain (such as maple and basswood) produce cleaner and more precise engravings, while woods with a heavy grain pattern (like oak) can make designs appear inconsistent.

Wood’s Color and Contrast

The natural color of the wood determines how well the engraving stands out. Lighter woods like maple, alder, and basswood create high-contrast engravings, while darker woods like walnut may require additional finishing techniques to enhance visibility.

Pre-Finished or Unfinished Wood

Unfinished wood is typically better for laser engraving because it allows for a more natural burn. However, if you choose pre-finished wood, ensure it does not have a thick coating, as some finishes can produce toxic fumes when burned.

The Best Wood for Laser Engraving

Several wood types tick all the boxes when it comes to laser engraving. However, if you are starting out, we suggest using any of the wood from this list:

Alder

As a softwood, alder has a supple texture and minimal streaking. It also features a nice light color that produces a pleasant dark burn. It has a few knots but these won’t affect the clarity of your engravings one bit. This is a good choice for the best wood for laser engraving.

Pros of Using Alder Wood for Laser Engraving and Cutting

- High Contrast Engraving – Engraves to a deep, dark brown, providing excellent visibility and readability.

- Fine and Even Grain – Produces smooth and detailed engravings without excessive grain interference.

- Minimal Scorching – Burns cleanly, reducing the chances of charred edges and excessive smoke marks.

- Lightweight and Soft – Easy to cut and engrave with a laser, requiring less power compared to denser hardwoods.

- Smooth Surface – Provides a polished, professional finish without the need for excessive sanding.

- Affordable and Readily Available – Cost-effective compared to premium hardwoods like walnut or maple.

- Consistent Results – Due to its uniform texture and predictable burning characteristics.

- Sustainable Choice – Grows quickly and is often sourced from responsibly managed forests.

Alder is an excellent choice for laser engraving and cutting, making it popular for signage, personalized gifts, and decorative wood projects.

This wood selection features top-quality A1-grade veneers on both sides, except for naturally knotty species like Knotty Alder and Aromatic Cedar. The 12×19-inch, 1/8-inch thick MDF-core sheets are ideal for laser engraving and cutting with Glowforge and other machines, offering consistent density without voids.

Various wood species are available, including Walnut, Cherry, Maple, Birch, Mahogany, and Bamboo. Birch boards have one natural and one white side for versatility. Available in six-packs of single species or a nine-wood sample pack.

Cherry

Cherry is popular for making cabinets and furniture across the planet. It also works well for laser engraving as it has low resin content. It has a light color and creates breathtaking engravings despite having high levels of streaking. Another great choice for the best wood for laser engraving.

Pros of Using Cherry Wood for Laser Engraving and Cutting

- High Contrast Engraving – Engraves to a rich, dark brown, making designs stand out clearly.

- Smooth and Fine Grain – Produces detailed engravings with minimal grain interference.

- Minimal Resin Content – Reduces scorching and excessive smoke compared to resin-heavy woods.

- Beautiful Natural Color – Reddish-brown tones give projects a warm, premium look.

- Durable and Strong – Offers a balance between hardness and workability, making it long-lasting.

- Polishes Well – Achieves a smooth, professional finish with minimal post-processing.

- Consistent Cutting Performance – Laser cuts cleanly with minimal burning on the edges.

- Ages Gracefully – Darkens over time, enhancing the natural beauty of engraved pieces.

Cherry wood is a top choice for high-end laser-engraved projects, including personalized gifts, plaques, and decorative items.

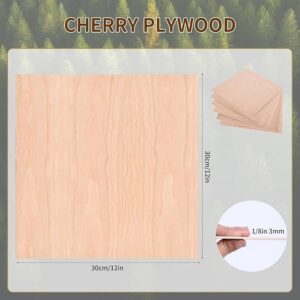

This set includes 24 pieces of 1/8″ x 12″ x 12″ cherry plywood, ideal for laser cutting, engraving, and DIY crafts. The smooth, unfinished wood is easy to cut, paint, and customize, making it perfect for modeling, decoration, and wood carving.

The durable, high-quality cherry wood resists warping and cracking, ensuring long-lasting projects. Great for making airplane models, houses, and other creative designs, these wood sheets also make thoughtful gifts for laser engraving enthusiasts.

Maple

Like cherry and alder, maple features a light color and burns dark for the most part. It has light streaking that makes it an excellent material for photo laser engraving. You wont go wrong with this choice for the best wood for laser engraving.

Pros of Using Maple Wood for Laser Engraving and Cutting

- High Contrast Engraving – Engraves to a dark brown, creating excellent visibility on the light-colored surface.

- Fine and Smooth Grain – Allows for sharp, detailed engravings with minimal grain interference.

- Hard and Durable – Strong enough to withstand laser engraving without chipping or splintering.

- Minimal Resin Content – Reduces excessive burning, smoke, and residue buildup.

- Consistent Cutting Performance – Cuts cleanly with smooth edges and minimal scorching.

- Versatile for Various Projects – Ideal for personalized gifts, signs, awards, and decorative items.

- Polishes and Finishes Well – Accepts stains and finishes beautifully for a professional look.

- Readily Available – Widely accessible and affordable compared to other hardwoods.

Maple is a top choice for laser engraving due to its smooth texture, durability, and ability to produce highly detailed designs.

These 100% pure hardwood maple planks are ideal for laser cutting, engraving, and crafting. With a high-density, straight grain and bright white color, they engrave and cut easily. Unlike plywood, these are solid maple with no veneer.

Each board measures 1/8″ x 4.5″ x 18″ and is compatible with most DIY tools. Perfect for personalized laser-engraved gifts, signs, and ornaments. The Hardwood Edge ensures kiln-dried, precision-cut, and chemical-free wood for high-quality results.

Basswood

Basswood is great for both laser engraving and cutting because it cuts well and is easy to work with. It can be easily stained, painted, and finished.

Pros of Using Basswood for Laser Engraving and Cutting

- Soft and Lightweight – Easy to cut with minimal power, reducing wear on laser components.

- Fine, Even Grain – Provides a smooth surface for detailed engravings with minimal grain interference.

- Low Resin Content – Reduces excess smoke and scorching, leading to cleaner engravings.

- Easy to Work With – Cuts cleanly with sharp edges, making it ideal for intricate designs.

- Light Natural Color – Engraves with good contrast, making designs stand out.

- Minimal Warping – Stays relatively stable, even in thin sheets, making it ideal for precision work.

- Affordable and Readily Available – Cost-effective option for laser cutting and engraving projects.

- Great for Staining and Painting – Easily takes stains, paints, and finishes for a polished look.

Basswood is an excellent choice for laser engraving and cutting due to its smooth texture, ease of use, and affordability, making it perfect for beginners and professionals alike.

This set includes 42 pieces of 12″ x 12″ x 1/8″ basswood sheets, ideal for laser cutting and engraving. Made from high-quality, environmentally friendly wood, they feature a smooth, durable surface with no warping or burrs.

Versatile and easy to machine, they are perfect for laser engraving and cutting, model making, painting, and crafting. Great for creating personalized gifts, these sheets offer strong stability for various woodworking projects. Quality control ensures customer satisfaction with reliable service and support.

Baltic Birch

Baltic birch is an excellent choice for laser engraving, especially for crafts and signage, due to the high contrast it produces. The light-colored wood darkens to a rich brown when engraved, making designs stand out clearly and enhancing visibility.

Pros of Using Baltic Birch for Laser Engraving and Cutting

- Durable and Strong – Baltic Birch is a high-quality plywood with excellent structural integrity, making it resistant to warping and cracking.

- Smooth, Even Surface – Provides a consistent engraving surface with minimal grain variation for detailed designs.

- High Contrast Engraving – The light-colored wood darkens beautifully when engraved, creating sharp, high-contrast results.

- Minimal Resin Content – Produces less smoke and residue, resulting in cleaner cuts and engravings.

- Multi-Layered Core – Offers stability and strength while allowing for precise cuts without splintering.

- Affordable and Readily Available – Cost-effective compared to solid hardwoods, making it ideal for bulk projects.

- Works Well with Stains and Finishes – Easily takes paint, stain, or sealants for enhanced visual appeal.

- Versatile for Various Applications – Suitable for signage, decorative items, puzzles, model making, and more.

Baltic Birch is a top choice for laser engraving and cutting due to its durability, smooth finish, and affordability, making it perfect for both professionals and hobbyists.

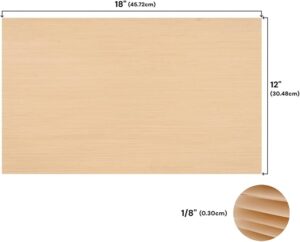

Premium Baltic Birch plywood is ideal for laser engraving, cutting, and various DIY projects. It features a smooth, uniform grain with a light color and durable B-BB grade quality, ensuring a clean surface without splices or patches.

Sized at 1/8″ x 12″ x 18″ (±0.19mm tolerance), it holds glue and screws well, making it perfect for arts, crafts, woodworking, and CNC laser cutting.

Walnut

Walnut has a rich, dark brown color that contrasts well with the lighter engravings, creating a striking effect. However, because walnut is a dense hardwood, it may require higher laser power settings for deep engraving. It is ideal for detailed designs, custom gifts, and high-end woodworking projects.

Pros of Using Walnut for Laser Engraving and Cutting

- Rich, Dark Aesthetic – Walnut has a deep brown color with varying tones, making engraved designs stand out beautifully without the need for additional staining.

- Fine and Consistent Grain – Provides a smooth engraving surface with minimal irregularities, ensuring detailed and precise results.

- Durable and Strong – Walnut is a hardwood with excellent structural integrity, making it resistant to warping and cracking.

- Engraves with High Contrast – The wood’s natural darkness contrasts well with lighter engraving marks, enhancing visibility.

- Premium Look and Feel – Often used in high-end woodworking projects, custom signage, and luxury items due to its elegant appearance.

- Works Well with Finishes – Takes oil, stain, and sealants beautifully, allowing for a polished final product.

- Good for Deep Engraving – Handles deep engraving well, making it suitable for intricate 3D designs and logos.

- Ideal for a Variety of Projects – Commonly used in custom gifts, furniture, plaques, awards, and decorative pieces.

Walnut is a top choice for premium laser-engraved products, offering a luxurious finish, strong contrast, and lasting durability.

This craft wood consists of 100% pure, thin-sawn walnut hardwood planks designed for laser engraving and cutting. Walnut has a medium density with a variable grain and color range from pale to dark brown, making it easy to engrave.

Unlike veneered plywood, these solid walnut boards are available in 1/8 or 1/4-inch thicknesses and work well with DIY tools. Ideal for crafts, gifts, personalized signs, and industrial arts projects, the wood is kiln-dried, precision-sliced, and sanded smooth without chemical treatments.

Comparison Table: The Best Wood For Laser Engraving

Here’s a comparison table of the best wood types for laser engraving, highlighting their characteristics, pros, and cons.

Wood Type | Engraving Quality | Burn Contrast | Hardness | Best For | Pros | Cons |

|---|---|---|---|---|---|---|

Basswood | Excellent | High | Soft | Detailed engraving, crafting | Smooth texture, minimal grain, easy to engrave | Can burn easily, may dent or scratch |

Baltic Birch | Very Good | Medium | Medium | Signs, decorations | Affordable, readily available, smooth surface | Can have inconsistent grain, slight charring |

Cherry | Excellent | High | Medium | Decorative projects, gifts | Beautiful natural color, strong contrast | Expensive, can darken more than expected |

Maple | Excellent | High | Medium | High-detail engraving, artwork | Fine grain, great for precise engraving | Can char slightly, color variation between batches |

Walnut | Very Good | Medium-High | Hard | Premium engraving projects | Rich dark color, deep engraving contrast | More expensive, hard surface requires higher power |

Alder | Excellent | High | Soft | Personalized gifts, signage | Soft, engraves easily, high contrast | Can be inconsistent in grain, prone to burning |

MDF | Good | Medium | Medium | Budget-friendly projects | Smooth, uniform surface, cheap | Releases fumes, not as durable as solid wood |

Oak | Good | Low-Medium | Hard | Rustic designs, furniture | Strong, durable, classic wood look | Deep grain can make engraving inconsistent |

Frequently Asked Questions

What type of wood is best for laser engraving?

The best types of wood for laser engraving are basswood, birch plywood, maple, cherry, and walnut. These woods have smooth surfaces and light colors, which produce clear and detailed engravings. Avoid woods with high resin content as they may scorch easily.

Should you wet wood before laser engraving?

No, you should not wet wood before laser engraving. Wetting the wood can cause uneven engraving results and may damage the laser engraver. It’s best to use clean, dry wood for optimal engraving quality.

Should I paint wood before laser engraving?

It’s generally better to paint wood after laser engraving. This avoids damaging the paint during engraving and allows for cleaner, more precise designs. However, if you need a specific background color, use masking tape to protect the painted surface during engraving.

Final Thoughts

Choosing the right wood for laser engraving can significantly impact the quality of your projects. By considering factors such as wood type, grain density, resin content, and color contrast, you can select materials that suit your design needs.

Softer woods like Birch and basswood are ideal for beginners, offering ease of engraving, while hardwoods like cherry or maple provide durability and a polished finish for professional results. Ultimately, the best wood for laser engraving depends on the intricacy of your design, your engraving equipment, and the desired final appearance. Experimenting with different woods can help you find the perfect match for your projects.