Laser engraving is a popular technique used to create detailed and permanent marks on a wide variety of materials, including metals, plastics, wood, and glass.

So how deep can laser engraving go?

The depth of laser engraving can vary significantly based on several factors, including the type of laser used, the material being engraved, and the specific settings and techniques applied. This article explores how deep laser engraving can go and what influences this depth.

Table of Contents

What Is Laser Engraving Depth?

Laser engraving depth refers to how much material is removed or vaporized during the engraving process. The deeper the engraving, the more pronounced and permanent your design will be.

Most laser engravings range between:

- 0.02 mm to 0.3 mm: Light surface engraving (logos, barcodes, serial numbers)

- 0.3 mm to 1.0 mm: Deep engraving (industrial plates, name tags, jewelry)

- 1.0 mm and above: Specialized deep engraving (dies, molds, embossing tools)

How Deep Can Laser Engraving Go with Different Types of Lasers?

CO₂ Laser Engravers

- Engraving Depth: 0.02 – 0.5 mm

- Best For: Wood, leather, acrylic, rubber, glass

- Details: CO₂ lasers are ideal for non-metal materials. With multiple passes, you can achieve engravings up to 1 mm deep, especially on wood and acrylic.

Fiber Laser Engravers

- Engraving Depth: 0.02 – 1.5 mm (up to 2 mm industrially)

- Best For: Metals such as stainless steel, aluminum, brass, copper, and titanium

- Details: Fiber lasers deliver high precision and deep penetration into metal. They’re perfect for industrial applications where durability and readability matter.

Diode Laser Engravers

- Engraving Depth: 0.01 – 0.3 mm

- Best For: Wood, coated metals, plastic, leather

- Details: Great for hobby and small business use. Diode lasers offer affordability and accuracy but are limited in depth compared to CO₂ or fiber models.

MOPA Laser Engravers

- Engraving Depth: 0.02 – 2 mm

- Best For: Metals such as stainless steel, aluminum, brass, copper, and titanium

- Details: Great for professional use. Applications include metal jewelry, tools, molds, and branding.

Typical Laser Engraving Depths by Material

Material | Typical Depth Range | Recommended Laser | Notes |

|---|---|---|---|

Wood | 0.5 – 1.5 mm | CO₂ / Diode | Fast engraving with high contrast |

Acrylic / Plastic | 0.2 – 0.8 mm | CO₂ / Diode | Adjust speed to avoid melting |

Stainless Steel | 0.02 – 1.0 mm | Fiber / 60W MOPA (2mm) | Durable and corrosion-resistant |

Aluminum | 0.02 – 0.8 mm | Fiber / 60W MOPA (1mm) | Ideal for ID plates and tools |

Leather | 0.1 – 0.5 mm | CO₂ / Diode | Deep enough for visible texture |

Glass / Crystal | 0.01 – 0.05 mm | CO₂ / UV | Produces frosted effect |

Rubber / Silicone | 0.1 – 0.3 mm | CO₂ | Great for stamps and molds |

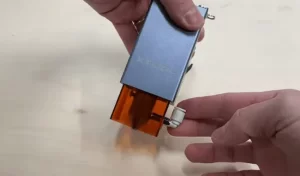

The Best Laser for Deep Engraving — The xTool F2 Ultra

If you’re looking for the most advanced deep laser engraving machine, the xTool F2 Ultra is an excellent option. Designed with professionals and small businesses in mind, it combines dual-laser technology — a 60W MOPA fiber laser and a 40W diode laser — to deliver unparalleled engraving depth, precision, and versatility.

Unlike traditional fiber lasers, the MOPA (Master Oscillator Power Amplifier) design provides a broader pulse and frequency range, unlocking color engraving, deep metal etching, and ultra-fine detail control — all in one compact powerhouse.

Why MOPA Is the Professional’s Choice for Metal Work

Stunning Color Engraving

The xTool F2 Ultra’s MOPA laser allows you to engrave over 100 vibrant colors on metals like stainless steel and titanium.

By precisely controlling pulse width and frequency, it delivers rich gradients and holographic effects, turning ordinary metal into art.

Perfect for jewelry, luxury branding, and custom metal gifts, this color-engraving capability adds significant value to your creations.

True Black Marking — No Sprays Needed

Say goodbye to messy marking sprays. The F2 Ultra produces deep, permanent black engravings with fewer passes, thanks to precise pulse modulation.

Whether you’re marking logos on stainless steel or serial numbers on tools, you’ll achieve crisp, professional results every time.

Faster 3D and Deep Engraving

With 60W of MOPA laser power, this engraver is five times faster than standard 20W fiber lasers when creating 3D textures or deep cuts.

It effortlessly engraves metal coins, nameplates, and relief patterns, making it ideal for businesses focused on precision metalwork or industrial marking.

Precision Metal Cutting

The F2 Ultra doesn’t stop at engraving — it also cuts thicker metal cleanly and efficiently.

For example, a 1 mm stainless steel name necklace can be cut in just six minutes, opening new revenue opportunities in jewelry, accessories, and custom branding.

Dual-Laser System: The Ultimate Creative Flexibility

The xTool F2 Ultra is the world’s first desktop machine to feature:

- 60W MOPA Laser — for deep metal engraving, color marking, and cutting

- 40W Diode Laser — for wood, leather, acrylic, plastic, and other non-metals

This combination makes it possible to engrave on virtually any material, from titanium and gold to wood and acrylic — all in one device.

AI-Powered Precision

Equipped with dual 48MP Hawk-Eye cameras, the F2 Ultra improves engraving accuracy by 60% compared to single-camera systems.

Its AI-driven software handles:

- Auto focus and color recognition

- AI image design generation (70+ styles)

- 3D object modeling for curved or irregular items

That means faster setup, smarter engraving, and consistent results — even for complex designs.

Professional ROI: Fast Payback and High Profitability

With its speed and flexibility, the xTool F2 Ultra isn’t just a tool — it’s a business asset.

For example:

- Brass Coins: $20 sale price, $5 cost, 20 sold monthly

- Name Necklaces: $50 sale price, $5 cost, 10 sold monthly

That’s an estimated 6.7-month payback period and an annual profit of around $9,000 (based on standard assumptions).

It’s a genuine ROI machine for creators, jewelers, and engraving entrepreneurs.

Key Specifications

Feature | xTool F2 Ultra |

|---|---|

Laser Power | 60W MOPA + 40W Diode |

Work Area | 220 × 220 mm (expandable to 220 × 500 mm) |

Max Speed | 15,000 mm/s |

Engraving Depth | Up to 2 mm (metals) |

Max Metal Cutting | Up to 2 mm |

Focus | Autofocus |

Cameras | Dual 48MP Hawk-Eye |

Software | xTool Creative Space (XCS), LightBurn compatible |

Material Support | Metals, wood, glass, acrylic, leather, plastic |

Connectivity | USB / Wi-Fi / IP |

Weight | 21.6 kg |

Safety & Air Filtration

Laser engraving metal produces fine dust and fumes — but xTool has that covered.

The xTool SafetyPro™ AP2 purification system uses a 6-layer cyclone filter, eliminating harmful gases and odors for a safer, cleaner workspace.

It even auto-activates when smoke is detected, ensuring worry-free operation.

Pros & Cons

Pros

- Deep and precise engraving on all metals

- 100+ color engraving options with MOPA technology

- Dual-laser system for both metal and non-metal materials

- Fast, AI-assisted workflow and autofocus

- Excellent ROI potential for businesses

Cons

- Premium price (professional-grade investment)

- Slight learning curve for dual-laser setup

- Requires proper ventilation and workspace

Final Verdict: The Ultimate Deep Engraving Machine

The xTool F2 Ultra is more than just an engraver — it’s a professional metalworking powerhouse that transforms creativity into profit.

With its MOPA-powered depth, color versatility, and cutting precision, it easily ranks as the best laser for deep engraving.

If your goal is speed, accuracy, and stunning results, the F2 Ultra is the machine that will take your engraving business to the next level.

Key Factors That Affect Engraving Depth

Laser Power

The wattage of your laser plays the biggest role. Higher wattage means deeper engravings:

- 10–20W → Light markings

- 30–50W → Moderate depth

- 60W+ → Deep engraving or cutting

Material Density

Dense materials like metal or stone require higher power and slower speeds compared to softer materials like wood or rubber.

Engraving Speed

Slower speeds allow the laser to stay longer on each spot, increasing depth — but be careful not to burn or warp your material.

Focus & Frequency

Perfect focus ensures the laser beam hits with maximum intensity. Adjusting pulse frequency allows for finer control over smoothness and depth.

Number of Passes

Performing multiple lower-power passes is often better than one high-power pass. It provides better control and prevents overheating or melting.

Deep vs. Shallow Engraving: Which Should You Choose?

Shallow Engraving

- Great for fine detail and surface marking

- Fast and clean

- Less durable for heavy-use items

Deep Engraving

- Long-lasting, tactile finish

- Resistant to abrasion and chemicals

- Requires higher power and time

If you’re engraving industrial tags or jewelry, deep engraving is the best choice. For decorative logos or personalized gifts, shallow engraving looks cleaner and faster to produce.

How to Increase the Depth of Laser Engraving

Laser engraving is a versatile technique used to create detailed and permanent marks on various materials. Sometimes, specific applications require deeper engravings for enhanced durability, visibility, or functionality.

Increasing the depth of laser engraving involves adjusting several factors related to the laser engraver’s settings, the material being engraved, and the engraving process itself. Here’s a guide on how to achieve deeper laser engravings.

Adjust Laser Power

Increase Laser Power:

- Higher Power Output: The most direct way to achieve deeper engravings is by increasing the laser power. Higher power increases the energy delivered to the material, allowing the laser to remove more material in each pass.

- Machine Specifications: Ensure your laser engraver supports the power level needed for deeper engraving. Some machines might have a maximum power limit that restricts how deep they can engrave.

Reduce Engraving Speed

Slower Speed for Deeper Cuts:

- Lower Speed Setting: Reducing the engraving speed allows the laser to spend more time on each point, which increases the amount of material removed.

- Balancing Speed and Power: A combination of higher power and slower speed can significantly increase the engraving depth but requires careful calibration to avoid damaging the material.

Increase the Number of Passes

Multiple Passes Technique:

- Repeated Engraving: Running multiple passes over the same area can gradually increase the depth of the engraving. Each pass removes a thin layer of material, allowing for controlled and precise deepening of the engraving.

- Cooling Periods: Allow the material to cool between passes to prevent overheating, which can affect the quality and consistency of the engraving.

Optimize Focus and Lens

Adjust Focus for Maximum Precision:

- Proper Focus: Ensuring the laser beam is properly focused on the material surface is crucial. The focal point should be as small as possible to concentrate the laser’s energy effectively.

- Adjustable Lenses: Some laser engravers come with adjustable lenses. Experiment with different focal lengths to find the optimal setting for deeper engraving.

Use Appropriate Materials

Material Selection:

- Material Properties: Different materials respond differently to laser engraving. Softer metals like aluminum or materials like acrylic will allow for deeper engravings more easily than harder metals like stainless steel.

- Pre-Treatment: Some materials can be treated or coated to enhance their engravability, making it easier to achieve deeper marks.

Utilize Pulse Settings

Pulse Frequency and Duration:

- Pulse Settings: Adjusting the pulse frequency and duration can influence the depth of engraving. Shorter, more intense pulses can create deeper engravings, especially on metals.

- Pulse Mode: Some laser engravers allow you to switch between continuous wave (CW) and pulsed modes. Pulsed modes are often better for deeper engravings as they concentrate more energy into each pulse.

Consider Assisted Gas

Gas Assistance:

- Air Assist: Using an air assist system can help blow away debris from the engraving area, allowing the laser to maintain its focus and efficiency.

- Inert Gases: For certain materials, using inert gases like nitrogen or argon can help achieve cleaner and deeper engravings by reducing oxidation and assisting in material removal.

Software Settings

Optimize Software Parameters:

- Engraving Parameters: Many laser engraving machines come with software that allows for detailed control over engraving parameters. Adjust settings like laser intensity, pass count, and line spacing for deeper engraving.

- Advanced Features: Some advanced software offers features like 3D engraving, where the software automatically adjusts power and speed to create deeper cuts at specific points in the design.

Cooling and Cleaning

Maintain Temperature and Cleanliness:

- Cooling System: Ensure your laser engraver has an adequate cooling system to prevent overheating, which can affect the depth and quality of the engraving.

- Clean Workspace: Regularly clean the lens and mirrors of your laser engraver to ensure maximum efficiency and power delivery.

Experimentation and Testing

Trial and Error:

- Test Runs: Perform test engravings on scrap material to fine-tune your settings without risking the final product.

- Documentation: Keep a log of successful settings for different materials and depths, which can serve as a reference for future projects.

Increasing the depth of laser engraving involves a combination of adjusting machine settings, selecting appropriate materials, and using proper techniques. By optimizing laser power, speed, focus, and other parameters, you can achieve deeper and more precise engravings.

Regular experimentation and careful documentation of your settings will help you refine your process and produce consistent, high-quality results. Whether you’re engraving for industrial applications, artistic projects, or personal use, these tips will enhance your ability to create deep and durable engravings.

Frequently Asked Questions

How deep can a laser engrave into different materials?

The maximum engraving depth depends on both the laser type and the material being engraved.

Wood: Up to 3–5 mm with a CO₂ laser using multiple passes.

Acrylic: Around 1–2 mm before melting or distortion occurs.

Metal: 0.02–2 mm using the xTool 60W MOPA laser.

Leather: Typically 0.1–0.5 mm for best texture and color contrast.

Glass: 0.05–0.2 mm — deeper engraving risks cracking or chipping.

Always start with a test engraving to find your material’s ideal depth.

What settings control engraving depth?

Engraving depth is mainly influenced by laser power, speed, and number of passes.

Higher power = deeper engraving.

Slower speed = longer laser exposure, resulting in more depth.

Multiple passes = allows deeper engraving without overheating the surface.

Other important factors include focus distance, line interval, and material density.

Why is my engraving too shallow or inconsistent?

Common causes include:

Low laser power output (check tube or diode health)

Incorrect focus height

High engraving speed

Dirty lens or mirrors reducing beam strength

Pro Tip: Clean your optics regularly and recalibrate focus for every new material thickness.

How can I achieve a deeper engraving without burning the material?

Instead of using excessive power in one pass, use multiple lighter passes at moderate power.

This approach gradually removes layers, keeps heat under control, and prevents burning or melting — especially on wood, leather, and acrylic.

You can also enable air assist to blow away debris and reduce surface temperature during engraving.

Does engraving depth affect durability or appearance?

Yes — engraving depth directly affects both longevity and visual contrast.

Deeper engravings are more durable and ideal for items exposed to wear, like metal tools or ID tags.

Shallower engravings preserve fine details and work best for decorative or delicate materials like glass or acrylic.

Tip: Match your engraving depth to your end use — deep for durability, shallow for detail.

Conclusion

The depth of laser engraving depends on various factors, including the type of laser, the material, and the settings used. Fiber and MOPA lasers are typically more effective for deeper engravings on metals, while CO2 lasers excel with non-metal materials.

By adjusting laser power, speed, focus, and the number of passes, you can achieve the desired engraving depth for your specific application. Whether you need shallow markings or deep engravings, understanding these variables will help you maximize the capabilities of your laser engraving machine.