Wood is a great material for your laser engraving projects. But one huge demerit with wood is the residue that the engraving machine leaves behind. In some cases, you might even have to deal with some burn marks on your material.

So, how do you clean laser engraved wood? There are three main methods of cleaning laser engraved wood:

- using hand soap

- light sanding

- using white vinegar

Table of Contents

Why Cleaning Laser Engraved Wood Matters

- Improves contrast – removing smoke stains makes your engraving stand out.

- Professional finish – eliminates scorch marks for cleaner results.

- Preserves durability – removing soot prevents buildup that can weaken finishes or sealants.

Common Issues After Engraving Wood

- Soot & smoke stains around engravings.

- Sticky residue from burning resin in softwoods.

- Uneven coloration where wood fibers absorb smoke.

Best Methods to Clean Laser Engraved Wood

Method 1: Using hand cleaner

- You will need an orange hand cleaner that is waterless and has no toxic chemicals or ammonia. A soft brush and paper towels will also come in handy.

- Place some of the hand clean on a soft brush and then use it to gently clean the surface.

- Check to ensure the wood is residue-free and then use a paper towel to give it one last polish with a little dab of the orange cleaner.

Method 2: Using light sanding

For this method, you will need smooth sandpaper to gently sand the engraved wood. Inspect the engraved area and use your discretion to sand off unwanted marks and burns but remember to be gentle to avoid ruining the intricate laser-engraved patterns.

- Use fine-grit sandpaper (220–400 grit on Amazon) to remove deep stains.

- Sand lightly to avoid flattening engraved details.

- Excellent for unfinished wood but not recommended on pre-finished surfaces.

Caution: Don’t use the sanding method on painted wood as it might scrape the paint and leave you with an ugly surface instead of the masterpiece you were aiming for.

Method 3: Using white vinegar

For this method, you will need a paper towel and white vinegar. To clean your laser-engraved wood, dab your paper towel in vinegar (you can also use a soft piece of cloth) and then use it to wipe off the residue on your wood. Repeat the process until you are satisfied with the result.

Comparison Table: Cleaning Methods for Laser Engraved Wood

Cleaning Method | How It Works | Pros | Cons | Best For |

|---|---|---|---|---|

Waterless Hand Cleaner (e.g., Fast Orange) | Apply a small amount of cleaner on a soft cloth and gently rub over the engraved surface to lift smoke stains and residue. | Safe for most wood types Effective at removing light smoke stains Quick and easy | May leave a slight oily residue Not as effective on deep burns | Everyday cleaning and light smoke stains |

Light Sanding | Use fine-grit sandpaper (220–400 grit) to gently remove the top layer of wood and any stains. | Very effective for tough stains Restores fresh wood surface Works on deeper burns | Risk of sanding away engraved details Time-consuming Dusty process | Deep cleaning or when other methods fail |

White Vinegar | Apply white vinegar with a cloth to break down smoke stains and disinfect the surface. | Natural and eco-friendly Inexpensive and widely available Removes odors as well as stains | Can slightly raise the grain Requires drying time Not ideal for all wood finishes | Budget-friendly cleaning and deodorizing |

Top Tips on how to clean laser engraved wood

- Avoid using any corrosive agents or coarse cleaning products as they could easily ruin your wood.

Test a small piece of wood first before you clean your engraved material. This will help you judge whether or not the cleaning supplies will actually work without leaving behind a mess. - Remember to clean your laser machine as well. Over time, the laser engraver will get lots of dust which combine with the resins to form a sticky mess that can cause your machine to malfunction.

How to reduce cleaning of laser engraved wood?

In general, cleaning time can be shortened in half by reducing the amount of smoke and residue produced during the engraving or cutting process.

The type of wood you use, as well as the thickness of the particular piece, can have a big impact on the final result. Speed, power, wattage, and your surroundings are all important considerations. As a result, we recommend conducting a materials test on an off-cut before you begin.

To improve the engraving outcome and reduce the cleaning work, consider the following points.

Don’t Engrave Too Deep

Only engrave as deep as is required for the desired outcome. This results in a brighter, more detailed engraving image as well as a significant reduction in smoke residue.

Correct Power & Speed Settings

When laser engraving wood, the first thing you can do is adjust the power and speed settings on the laser engraving machine. If the laser emits too much power, it will undoubtedly leave burn marks. High power begins to burn the wood and particles at the edge of the engraving. As a result, you must reduce the power as much as possible.

Speed is also vital in avoiding burn marks. When the speed is too slow, the laser beam spends a long time on the area, leaving burn marks as a result. The speed should be high enough to minimize burn marks.

Reduce the laser power and/or increase the laser speed settings as needed to get the best results. You can experiment with different settings to avoid scorching. Once you’ve found the setting that works best for each type of wood, make a note of it to speed up the procedure in the future.

Engrave from the bottom up

Engrave from the bottom up so the smoke is drawn away from rather than over the etched region. The amount of residue that can settle on the (hot) engraved area is reduced as a result.

Use a Honeycomb Table

Excessive heat is produced when a laser beam hits your material. It is critical to evacuate the heat otherwise, the temperature of the wood will rise. This will undoubtedly result in burn marks if the heat dissipation is inadequate. For engraving, a honeycomb table is always recommended. It not only protects the table area beneath it, but it also prevents burn marks due to its excellent heat dissipation.

For detailed information on the honeycomb tables we recommend for laser engravers, it would be helpful to read this article I wrote here.

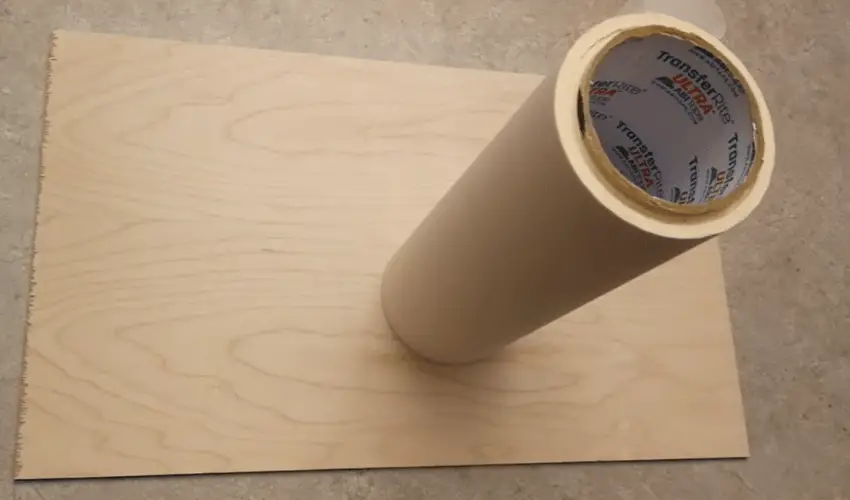

Use Laser Engraving Transfer Tape

Laser engraving transfer tape is a great way to avoid burns when engraving on wood. When you apply the tape, it is the first thing that comes into contact with the laser beam. It prevents burn marks by reducing the smoke and fumes produced during the engraving process. The tape can be pulled off the surface after laser engraving, you will have a clean edge but it is time-consuming to apply and remove the tape.

We don’t like to use masking tape as it is not adhesive enough. We use paper transfer tape, but not vinyl or plastic transfer tape. Do not use a laser to engrave or cut vinyl since it emits harmful chlorine into the air. This type of paper transfer tape is commonly used by Cricut users for vinyl signs, shirts, stickers, and other projects, and it comes in a variety of roll widths to suit your needs.

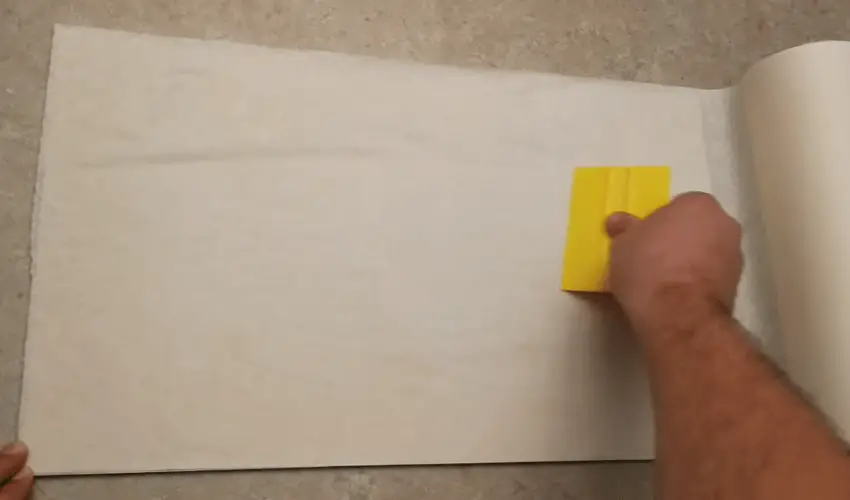

How To Apply Transfer Tape

- Apply the transfer tape smoothing out any bubbles or creases with a Squeegee as you go.

- Then, set the laser engraver’s power and speed and engrave the wood as desired.

- Remove the tape when the engraving is finished.

While transfer tape can help prevent burn lines when laser engraving wood, it is not always required. By carefully adjusting the laser engraver settings and utilizing a lower-power setting, it may be able to produce good results without requiring transfer tape.

Use Air Assist with your Laser

Smoke is created from the surface of the wood as a result of the engraving. This smoke collects around the material, causing a temperature rise. Burn marks are a result of this high temperature. The smoke can be blown away with the use of an air assist.

An air assist is a vital component of a laser engraver. It delivers a consistent and high-pressure airflow to blow away the hot smoke, which results in reduced burn marks. Also, make sure you are using an exhaust fan, fume extractor, or enclosure to reduce smoke around and on your workpiece.

Our Buying Guides Can Be Found Here:

Top 5 Laser Engraver Exhaust Fan Options

Top 5 Best Fume Extractors for Laser Engravers

Laser Engraver Enclosure Options: You Need The Best Quality

Recommended Products To Clean Laser Engraved Wood

- Fast Orange Hand Cleaner

- Fine-grit sandpaper (220–400 grit)

- Distilled White Vinegar

- Greenstar TransferRite Ultra Transfer Tape (Preventive Measure)

Frequently Asked Questions – FAQ’S

How do you remove smoke stains from laser engraved wood?

Smoke stains are common after engraving. The easiest way to remove them is by wiping the surface with a waterless hand cleaner. For tougher stains, use white vinegar on a soft cloth. Avoid soaking the wood to prevent warping.

Can I sand laser engraved wood to clean it?

Yes, but use fine-grit sandpaper (220–400 grit) and sand lightly. This is especially helpful for removing deeper stains or resin buildup. Be careful not to sand away the engraved details.

Is it safe to use soap and water on laser engraved wood?

Generally, no. Excess water can cause swelling or damage. A slightly damp cloth is fine, but avoid soaking the surface. For cleaning, a waterless hand cleaner is a safer option.

How do I protect the laser engraved wood after cleaning?

After cleaning, apply a protective finish such as mineral oil, beeswax, or a clear polyurethane coat. This not only enhances the wood grain but also prevents future stains and makes cleaning easier.

How can I prevent burn marks when engraving wood?

You can reduce burn marks by applying transfer tape over the engraving area before lasering. Another option is to use an air assist attachment, which helps blow away smoke and debris during the engraving process.

Final thoughts

Cleaning laser engraved wood is simple with the right techniques. Whether you brush, wipe, or sand, you can remove smoke stains and achieve a professional, polished finish. For best long-term results, combine good engraving settings, proper masking, and protective sealing.

With these tips, your wood engravings will look sharp, clean, and ready to impress.