Laser cutting/engraving is an effective way of making precise and accurate edges on your wood, plastic, or other projects. However, laser cutter burn marks have been a common challenge to most people to the extent of losing hope, which should not be the case. But the biggest barrier is how to do it perfectly without the laser cutter burn marks.

How do you prevent burns from laser cutting? Laser cutter burn marks are a result of soot, fumes, and debris from the machine. You can prevent burns by using transfer tape, coating, and polish, using air assist, adjusting the power settings, using a honeycomb table, adjusting the power settings, or immersing the wood in water.

Let’s look at each of these in greater detail below.

Table of Contents

How do you prevent burns from laser cutting

There are several easy and effective ways of preventing the burn marks from laser engraving while using the proper tools and guidelines. They include:

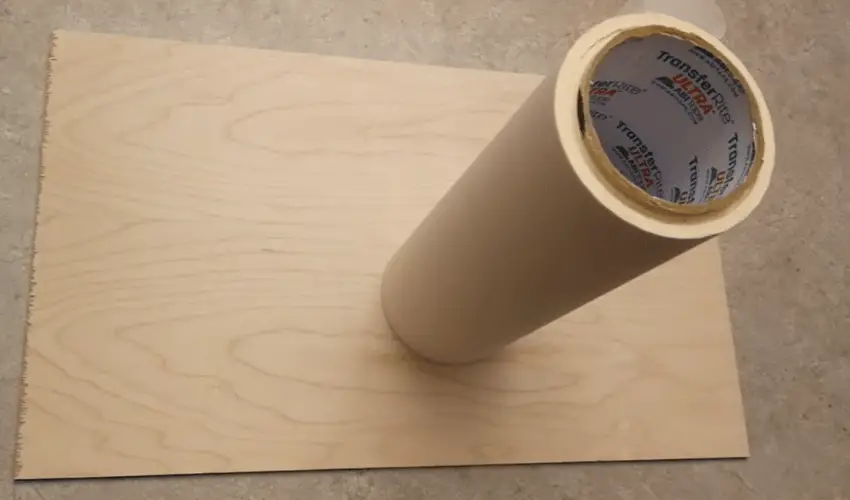

1. Using a paper transfer tape / application tape

Generally, laser engravers have tried using masking tape, which works close to a paper transfer tape to prevent laser burning, but didn’t work very effectively. A paper transfer tape is designed to work perfectly for this job, while it is also available in wide rolls.

This is an easy to prepare method that helps in preventing the fumes from burning your edges or depositing soot on your wood surface. This method works by evenly spreading the transfer tape on the surface, ensuring that no air bubbles are left.

To achieve maximum efficiency, it is ideal to use a plastic or a plastic squeegee to flatten the tape evenly. Note that air bubbles can worsen the cutting process and results. However, this method can be time-consuming while removing the tape.

We use the GreenStar Application Transfer Tape. Amazon Link can be found here - Paid Link. For the all the best materials for your laser cutting and engraving projects then check out this informative article I wrote on the subject.

2. Using a coat and a polish

This method works by applying a coat before cutting, then using a wood polish to remove any burn marks. This method works easily and effectively. First, apply a coat on the surface, and then use your laser cutter to cut.

The coat helps in cleaning the wood surface to remove all the burned residue, and preventing the burnt matter from reaching the wood grain. Finally, a wooden polish or denatured alcohol helps in removing the marks easily due to the smooth coating.

3. Dip thin wood in water

This method is ideal for thin plywood or small pieces of wood that can be easily immersed in water. Dipping the wood before cutting it prevents scorching or burning while laser cutting.

4. Adjust the laser cutter power settings

Sometimes, you don’t have to use various methods to prevent burning. All you need is to find the ideal speed and power settings of your laser cutter, to get fewer burn marks. However, finding the ideal settings can be time-consuming, while different types of wood require different settings, making it more difficult.

Adjusting the laser cutter focus in a way that it zooms out slightly can help prevent the burn marks. Also, a bit more diffuse laser helps in reducing the amount of smoke produced.

5. Using air assist

This method does not necessarily prevent the wood from burning, but it helps prevent it to an extent and even effective with some individuals. This is due to the slight differences in air and setup. Generally, you should learn how to use air assist, as it can help you in preventing laser burn marks.

However, learning the skills of using it effectively to avoid laser burns involves trial and error and requires more practice.

6. Using a Honeycomb Worktable

If you are using a Diode Laser for your wood cutting and engraving then in most cases you are cutting and engraving directly on your work surface. If this case it would be worth investing in a honeycomb worktable as this will reduce burn marks by providing increased airflow.

Apart from structural support for your materials it also absorbs energy and diffuses light to improve cut and engraving results.

Below you will find the article I wrote on the best honeycomb laser engraver beds: Best Honeycomb Laser Engraver Bed

How to remove laser cutter burn marks?

Laser cutting is very effective, but your whole project can be destroyed by the same machine. Burnt edges and marks on the surface of your wood can render your project a failure. However, there are ways of removing or cleaning the burn marks from your project. They include:

- Using a brush and pumice liquid soap

You can get rid of the laser cutter soot and burn marks from the wood surface by using a toothbrush and pumice liquid soap to scrub. Usually, the pumice granules do the work of sandpaper, while the toothbrush helps to scrub and reach the tight spaces. Scrub the marks for about 2 – 3 minutes to completely remove the soot.

- Using sandpaper

Using sandpaper to sand the wood surface can also do the trick and is an easy way to solve the problem. Use sandpaper with medium grit to remove all the burn marks from the wood, and finally use sandpaper with a higher grit to make an attractive and smooth finish. You can also use sheet sanders to remove the laser burn marks, which is also ideal as they are quick and easy to control while you can easily add your sanding paper.

- Using denatured alcohol

Denatured alcohol is the last option and the most effective way to remove the stubborn marks from your project. To remove the marks, pour a small amount of the denatured alcohol into a piece of cloth and then use it to wipe off the stubborn marks.

Tips for preventing laser cutter burn marks

The following are more tips for enhancing your laser projects to get the cleanest and lightest finish.

- Use multiple methods of preventing burn marks in your project to achieve the best results

- Use mineral spirits and a piece of cloth to clean the wood edges and surfaces

- Use a lower power setting

- Apply furniture polish to the surface before cutting, as well as wiping the light soot stains

- Change the PPI or frequency of your machine.

- Try using black acrylic to get a perfect finish.

- Use a transfer tape for your wood cutting and engraving projects.

Conclusion

Laser cutters are great machines for making exclusive wood projects. However, the results might be rendered bad by the same laser cutter due to the burn marks and soot stains. But this should not stop you from working on your project.

Preventing these burn marks and stains can be easier than it seems. The above article has provided you with various methods of preventing laser cutter burn marks easily, as well as how to easily remove the burn marks. Use this article to get the best and cleanest results on your laser cutter projects.

Check Out Our Buying Guide: Best Laser Engraver for Woodworking