3D laser engraving is an advanced technology that uses lasers to create detailed, three-dimensional designs on various materials. Unlike traditional engraving, which only etches the surface, 3D laser engraving allows for the creation of intricate depth and texture, giving the engraved design a more lifelike appearance.

Table of Contents

In this article, we’ll explore what 3D laser engraving is, how it works, its applications, and the benefits of using this innovative technique.

How Does 3D laser engraving work?

3D laser engraving involves using a laser beam to etch a design into a material, layer by layer. The laser removes material at varying depths, which creates the illusion of depth and texture. The process is typically controlled by specialized software that translates a 3D model or design into instructions for the laser machine. This allows for precise control over the engraving depth, ensuring that the design is accurately reproduced.

Steps in the 3D Laser Engraving Process

- Design Creation: The first step involves creating a 3D model of the design using CAD (Computer-Aided Design) software or similar design tools.

- Material Preparation: Materials such as wood, metal, acrylic, glass, or stone are commonly used for 3D laser engraving. The choice of material impacts the final look and durability of the engraving.

- Laser Setup: The design is uploaded to the laser machine, and settings such as power, speed, and focus are adjusted according to the material.

- Engraving Process: The laser begins engraving the design layer by layer, carefully following the depth variations outlined in the digital design.

- Finishing Touches: Once engraving is complete, the piece may undergo finishing processes like polishing, staining, or painting to enhance the appearance.

Key Applications of 3D Laser Engraving

3D laser engraving has a wide range of applications across various industries:

- Personalized Gifts and Awards: 3D laser engraving is popular for creating custom plaques, trophies, and personalized gifts with intricate designs.

- Jewelry: It is used to engrave detailed designs onto metal jewelry, including rings, necklaces, and bracelets.

- Architecture and Model Making: Architects use 3D engraving for creating detailed models and prototypes with accurate depth and texture.

- Signage: Businesses utilize 3D laser engraving to produce high-quality signs with detailed logos, lettering, and graphics.

- Industrial Applications: In industries, 3D engraving is used for creating durable, high-precision parts, serial numbers, and labels.

Benefits of 3D Laser Engraving

- Precision and Detail: The level of accuracy and detail achieved with 3D laser engraving is unparalleled. Even the smallest features of a design can be captured with remarkable clarity.

- Durability: Engravings are long-lasting and resistant to wear, especially when done on tough materials like metal or glass.

- Versatility: 3D laser engraving works on a wide range of materials, offering versatility for various applications.

- Customization: Whether for personal gifts or industrial parts, the ability to customize each design makes 3D laser engraving a valuable tool.

- Non-Contact Process: Since the laser beam does not physically touch the material, there’s minimal risk of damage or deformation, even on delicate materials.

Suitable materials for 3D laser engraving

3D laser engraving doesn’t work for all materials that might support 2D laser engraving. Stone, for instance, is not a good candidate for any 3D engraving project. This is because it is too hard and poses a challenge of burning the material without having the beam travel all the way through the material.

Hardwood

This is undoubtedly the most ideal material for 3D engraving in the industry. Hardwood species such as birch, cherry, walnut, and maple are characterized by a fantastic grain structure that best highlights the engraving details. Sure, the wood will be burnt during the laser engraving but the soot is quite easy to clean up using water.

Also Read: 3D Engraving on Wood - Tips for best results

Acrylic

Acrylic comes at a close second to wood when doing three-dimensional laser engraving. Although harder than wood, acrylic has an impressive melting point that is capable of producing great 3D designs and images.

However, if you are using clear acrylic, you may have to make a second pass with the machine to perfectly gloss or polish the surface of the engraving.

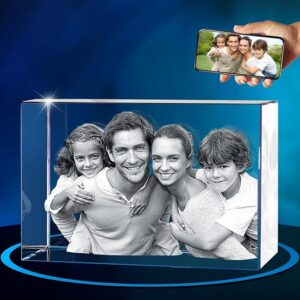

Crystal

Crystal has a clear and reflective quality, making it an excellent medium for 3D engravings that require depth. Commonly used for personalized gifts, such as photo cubes and awards. It is important to use a laser with appropriate settings to avoid damaging the crystal.

Medium Density Fiberboard (MDF)

If you are looking for an engraved product that you can paint later, consider using MDF. It is soft, readily available, and quite affordable. Once you are done engraving, you can clean the surface using an air hose and a damp cloth and then proceed to paint it.

Considerations When Using 3D Laser Engraving

While 3D laser engraving is highly effective, there are a few factors to consider:

- Material Choice: Not all materials are equally suited for 3D laser engraving. Some may require special preparation or post-processing to achieve the desired results.

- Laser Power and Settings: The laser’s power, speed, and focus must be adjusted based on the material and design. Inappropriate settings may result in poor quality or damage to the material.

- Cost: The equipment and software required for 3D laser engraving can be expensive, especially for commercial use.

3D Crystal Laser Engraving

3D crystal laser engraving is a unique and mesmerizing technique that involves engraving intricate designs, images, or text inside a crystal using a laser. The result is a stunning 3D image that appears to be floating within the crystal, making it a popular choice for personalized gifts, awards, and keepsakes. This guide will cover everything you need to know about 3D crystal laser engraving, from the process and materials to its common uses and benefits.

What Is 3D Crystal Laser Engraving?

3D crystal laser engraving is a process that uses a laser to etch a design into the interior of a crystal block, cube, or other shapes. Unlike traditional engraving, where the surface of the material is cut or etched, 3D laser engraving creates a design within the crystal itself. The laser beam creates tiny fractures or points within the crystal, which come together to form the desired image or text in 3D.

This process works by focusing the laser at specific points within the crystal, without damaging the outer surface, resulting in a 3D image that can be viewed from various angles. The engraved design often appears suspended in the crystal, creating a captivating effect.

How Does 3D Crystal Laser Engraving Work?

The process of 3D crystal laser engraving involves several key steps:

- Design Creation:

- The process begins with a 3D model or design, often created using software. This could be a 3D representation of a person’s face (from a photograph), a logo, text, or another custom design.

- Software is used to convert the image into a 3D format that the laser can recognize and engrave.

- Laser Engraving:

- The crystal is placed in a laser engraving machine. The laser is focused at specific points inside the crystal, where it creates micro-cracks or points, which eventually form the overall 3D image.

- The laser operates in a controlled manner, ensuring that the points are placed accurately and precisely to achieve the desired depth and detail. The number of points required depends on the complexity of the design.

- Completion:

- After engraving, the crystal is carefully removed from the machine, and the image is now permanently embedded within the crystal. The outer surface of the crystal remains smooth and untouched.

What Materials Are Used for 3D Crystal Laser Engraving?

The most commonly used material for 3D laser engraving is optical crystal, also known as K9 glass. Optical crystal is highly transparent and free from impurities, making it ideal for laser engraving. Its clarity ensures that the 3D image within is sharp, detailed, and clearly visible.

Some of the most common shapes used for 3D crystal laser engraving include:

- Cubes

- Rectangular blocks

- Hearts

- Spheres

- Towers or obelisks

While optical crystal is the most popular choice, other materials like glass can also be used for this process. However, optical crystal is preferred for its flawless quality and ability to display fine details.

Common Uses of 3D Crystal Laser Engraving

- Personalized Gifts:

- 3D crystal engravings are often used for personalized gifts, such as custom 3D portraits, family photos, or romantic messages. These make for memorable gifts for weddings, birthdays, anniversaries, and other special occasions.

- Corporate Awards and Trophies:

- Many businesses use 3D laser engraving to create stunning crystal awards and trophies. Logos, names, and achievements can be engraved in 3D, giving the awards a unique and professional appearance.

- Memorials and Keepsakes:

- 3D crystal engravings are also used as memorials, where a photo of a loved one or a cherished moment is immortalized in crystal.

- Decorative Items:

- Home and office décor items, like engraved crystal paperweights or decorative crystal blocks, often feature intricate 3D designs.

- Corporate Branding:

- Companies can use 3D laser engraving for marketing purposes, by creating branded crystal items like keychains, paperweights, or display pieces that feature their logo or slogan.

Benefits of 3D Crystal Laser Engraving

- Durability:

- 3D crystal engravings are long-lasting and highly durable. The design is embedded inside the crystal, ensuring it will not fade, wear, or be damaged over time. The outer surface remains smooth, protecting the image from external elements.

- Precision and Detail:

- The laser engraving process is highly precise, allowing for intricate details to be captured in 3D. This level of accuracy makes it possible to engrave even the most complex designs, including lifelike portraits and fine text.

- Personalization:

- One of the greatest advantages of 3D crystal laser engraving is the ability to create fully personalized products. Whether it’s a photo, logo, or text, the customizability makes it a popular choice for special occasions and corporate gifts.

- Visual Appeal:

- The 3D effect of the engraving gives the design a floating or suspended appearance, which is visually striking. The crystal’s clarity enhances the image, making it appear almost holographic when viewed from different angles.

- Low Maintenance:

- Since the engraving is inside the crystal, it requires minimal maintenance. A simple wipe to clean the crystal surface is enough to keep it looking pristine.

Things to Consider When Choosing a 3D Crystal Engraving

- Size and Shape of the Crystal:

- The size of the crystal will determine the level of detail you can achieve with the engraving. Larger crystals allow for more intricate designs, while smaller crystals are best suited for simple images or text.

- The shape of the crystal should complement the design you choose. For instance, a rectangular block may be better suited for portraits, while a heart shape is ideal for romantic messages.

- Design Complexity:

- Highly detailed or complex images require more laser points, which can affect the time and cost of engraving. Simple designs may be more affordable and faster to engrave.

- Laser Machine Quality:

- The quality of the laser engraving machine plays a significant role in the final product. High-quality machines can produce more detailed and precise engravings. We recommend the HeatSign 3D Crystal Laser Engraving Machine HS-GL20P. Here is the link to the HeatSign 3D Crystal Engraver.

Buy The Best 3D Crystal Engraving Photo

The ArtPix 3D Crystal Engraving Photo is an impressive and elegant option for those seeking a personalized gift that leaves a lasting impression. This custom 3D engraved crystal is perfect for anyone looking to celebrate special moments, whether it’s for a loved one, family member, or friend.

The ability to upload your own photo for the engraving makes this product a highly customizable and thoughtful gift, ideal for birthdays, anniversaries, holidays, or simply as a cherished keepsake. The product stands out for its high-quality craftsmanship, crystal clarity, and the captivating 3D effect that brings photos to life.

Key Features:

- Customizable 3D Engraving: Upload a photo of your choice, and ArtPix will create a stunning 3D rendering inside the crystal.

- High-Quality Optical Crystal: Made from premium-grade K9 optical crystal, known for its clarity and durability.

- Perfect for All Occasions: Ideal for personalized gifts for birthdays, anniversaries, weddings, and more.

- Multiple Sizes Available: Choose from a range of sizes to fit your needs, from small tokens to larger statement pieces.

- Illuminating Base: An optional LED light base is available, enhancing the visual appeal by illuminating the crystal from below.

Pros:

- Stunning Visual Impact: The 3D engraving effect is sharp and lifelike, creating a beautiful floating image that can be viewed from different angles.

- Personalized Touch: The ability to use your own photo adds sentimental value, making it a perfect gift for loved ones.

- Durability: The crystal is highly durable, ensuring that the image remains intact and protected for years to come.

- Optional Light Base: The LED light base option enhances the overall aesthetic, making the crystal stand out even more as a decorative piece.

- Versatile Gift Option: Suitable for various occasions, including weddings, birthdays, Mother’s Day, Father’s Day, or anniversaries.

Cons:

- Price: The cost can be on the higher side, especially for larger crystals or when adding optional accessories like the light base.

- Shipping Time: Custom orders may take longer to arrive due to the production process involved in creating a 3D engraving.

- Limited Detail for Complex Images: While the engraving is detailed, very intricate or busy photos may lose some clarity in the 3D conversion process.

The ArtPix 3D Crystal Engraving Photo is a memorable and eye-catching gift option that offers a unique way to preserve and display cherished memories. Its personalized touch, combined with the impressive 3D effect, makes it a standout choice for special occasions.

While it may come with a higher price tag, the quality and emotional value of the product make it well worth the investment. Perfect for anyone looking for a meaningful and lasting gift!

3D crystal laser engraving is an innovative and captivating way to create personalized gifts, awards, and keepsakes. Whether you’re engraving a custom photo, a company logo, or a meaningful message, the precision and durability of this process make it an excellent choice for lasting, visually stunning designs.

With its versatility in design, material options, and wide range of uses, 3D crystal laser engraving continues to be a popular and creative solution for those looking to make a lasting impression.

What is the difference between 2D and 3D laser engraving?

The difference between 2D and 3D laser engraving lies primarily in the depth and complexity of the engravings produced. Here’s a breakdown of each:

2D Laser Engraving

- Definition: 2D laser engraving involves creating flat images or designs on the surface of a material. The engraving is done by removing material from the surface to create a contrast with the background.

- Depth: The engraving is typically shallow, meaning it doesn’t penetrate deeply into the material.

- Applications: Commonly used for logos, text, or simple graphics on materials like wood, glass, metal, and acrylic.

- Visual Effect: The result is a flat, one-dimensional image that can vary in darkness or lightness based on the engraving’s intensity.

- Tools and Techniques: 2D laser engraving machines often use vector images, and the process can be quick and efficient for mass production.

3D Laser Engraving

- Definition: 3D laser engraving creates a three-dimensional image that appears to have depth and texture. This process involves not only the surface but also varying depths within the material to create lifelike images.

- Depth: The engraving penetrates deeper into the material, allowing for more complex designs and shadow effects.

- Applications: Commonly used for creating sculptures, portraits, and intricate designs in glass, crystal, wood, and metals. It’s popular for gifts, awards, and decorative items.

- Visual Effect: The finished product has a three-dimensional appearance, with highlights and shadows that give the image a realistic look and feel.

- Tools and Techniques: 3D laser engravers typically require specialized software to convert images into a format suitable for three-dimensional engraving, and the process can be more time-consuming than 2D engraving.

In essence, the main differences between 2D and 3D laser engraving are the depth of engraving and the complexity of the images produced. While 2D engraving is more straightforward and efficient for flat designs, 3D engraving allows for more artistic and realistic representations, making it ideal for personalized and decorative items.

Why is 3D laser engraving necessary?

3D laser engraving has become increasingly popular due to its ability to produce intricate and detailed designs that enhance various applications. Here are several reasons why 3D laser engraving is considered necessary:

1. Enhanced Visual Appeal

- Depth and Texture: 3D engraving creates images with depth and texture, making them visually striking and more appealing compared to flat 2D engravings. This dimensionality can significantly enhance the aesthetic value of products, especially in gifts, awards, and decorative items.

2. Customization and Personalization

- Unique Gifts: 3D laser engraving allows for the creation of personalized items, such as custom portraits, memorials, or keepsakes. This level of personalization makes gifts more meaningful and memorable.

- Brand Identity: Businesses can use 3D engraving to create unique branded items, enhancing their identity and standing out in the market.

3. Versatile Applications

- Variety of Materials: 3D laser engraving can be applied to various materials, including glass, crystal, wood, metal, and acrylic. This versatility makes it suitable for numerous industries, including jewelry, home decor, awards, and signage.

- Functional Items: Beyond aesthetics, 3D engraving can be utilized in functional applications, such as creating detailed engravings for control panels or decorative elements in architecture.

4. Precision and Detail

- Complex Designs: 3D laser engraving can achieve intricate details that are challenging to replicate with traditional engraving methods. This precision allows artists and designers to create complex and lifelike representations.

- Repeatability: Laser engraving ensures consistent quality across multiple items, making it easier to produce uniform products for branding or promotional purposes.

5. Market Differentiation

- Competitive Edge: Businesses that utilize 3D laser engraving can differentiate themselves from competitors. Offering unique, high-quality products can attract customers looking for something special.

- Innovation: 3D engraving technologies are continually evolving, allowing businesses to stay ahead of trends and incorporate new design techniques.

6. Cost-Effective Production

- Low Material Waste: Laser engraving is precise, which reduces material waste compared to other methods of manufacturing. This efficiency can lead to cost savings in production.

- Quick Turnaround: Modern 3D laser engravers can operate at high speeds, allowing for rapid production times without sacrificing quality.

7. Durability

- Long-Lasting Designs: Laser-engraved items tend to be more durable since the engraving is etched into the material rather than just applied to the surface. This permanence can be especially important for items meant for long-term use, such as awards or industrial components.

How to make 3D laser engraving easier

Buy the right laser machine

Perhaps the most important thing to keep in mind before any 3D laser engraving project is the choice of the machine to be used. Apart from getting a laser that can interpret a wide range of color shades, you need one capable of quick pulse durations.

There’s an unwritten rule that lasers with radio frequency (RF) ceramic or metal tubes do a better job than those with direct current (DC) tubes when it comes to 3D engraving. Scientifically, RF lasers offer quicker pulse rates that are perfect for 3D projects whereas DC lasers are characterized by a lower modulation speed that fails to fire quickly like RF lasers.

The laser machine should also be powerful enough to be able to handle massive engraving projects in no time. The recommended wattage for 3D laser engraving is 100-400 watts. In all honesty, lower-wattage machines will still get the job done but higher-wattage lasers will give you total relief depth plus a much larger variation between the maximum and minimum depth areas.

We recommend the HeatSign 3D Crystal Laser Engraving Machine HS-GL20P. Here is the link to the HeatSign 3D crystal engraver

Get the appropriate depth of the engraving

You also need to give thought to the depth of your 3D engravings. If you are using wood, it is easy to make deep cuts because the machine can cut through a one-inch wood piece with relative ease. However, you might want to keep your engravings shallow to clearly display your engravings. It is a good option to keep your engraving depth in the range of 1/8” and ¼”.

The artwork should be perfectly designed

The most challenging part of the 3D laser engraving is creating the pattern and design. If you are a beginner, it can be time-consuming and brain-racking. Thankfully, you will get the feel of things before you know it. Design software typically use a palette or grayscale to create high-resolution 3D graphic designs and images.

Your designs should be clear in order to create equally eye-catching 3D logos, picture frames, cutting boards, and other products. This means that you have to properly understand the specific software you are working with. You should be able to shade your artwork in gray so that you determine the depth of your image.

The best graphic design software is one that is 8-bit or one that correlates to all the 256 shades of gray between white and black. Some of the popular software that meets these criteria are Photoshop, CorelDraw, Adobe Illustrator, and ArtCAM.

Be patient

From getting the artwork right to varying the depth of the engraving, you need a generous amount of patience to nail 3D laser engraving. The time taken depends on the laser power, the resolution of your artwork, and its size.

Once you get the hang of things, you’ll know the right balance for these parameters to get quality 3D engraving using the least amount of time possible. But patience is an important virtue when it comes to 3D laser engraving.

Also Read: The Best 3D Printer Laser Engraver

Conclusion

3D laser engraving is a cutting-edge technology that opens up a world of possibilities for creating detailed, durable, and customized designs. Whether for personal use, business signage, or industrial applications, its ability to precisely engrave materials with depth and texture makes it a valuable tool across multiple industries. By understanding how it works and the benefits it offers, you can make the most of this powerful technology.