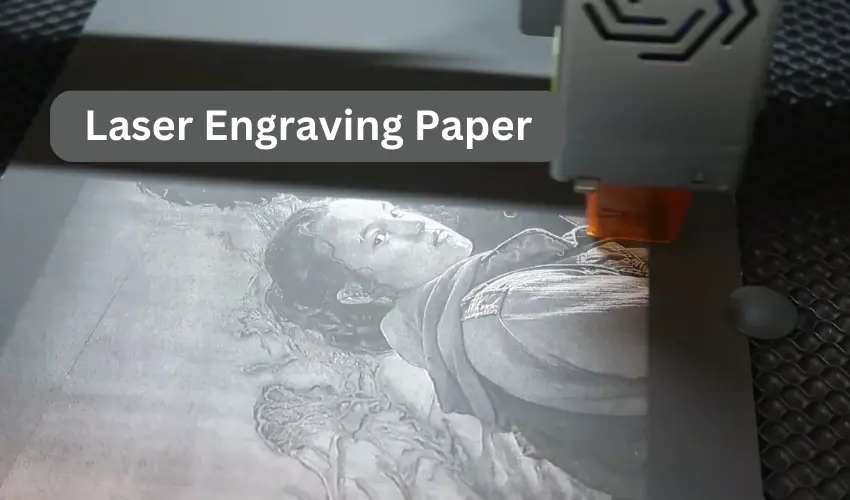

Laser engraving is a fascinating technology that allows us to create detailed designs on various materials, including wood, metal, plastic, and even paper. Yes, you heard it right – paper! Laser engraving on paper opens up a world of creative possibilities, from personalized greeting cards to intricate artwork.

In this article, we’ll explore everything you need to know about laser engraving on paper.

Table of Contents

What is Laser Engraving?

Laser engraving is a process that uses a focused beam of light (laser) to etch or cut designs into a material. The laser beam removes a thin layer of the material’s surface to create the desired pattern. The result is a permanent, precise, and detailed engraving that can be customized to your specifications.

Why Use Laser Engraving on Paper?

Paper might seem like a fragile material for laser engraving, but it can produce stunning results. Here are some reasons why you might want to use laser engraving on paper:

- Precision: Laser engraving can create highly detailed and intricate designs that are difficult to achieve with traditional printing or cutting methods.

- Customization: Each piece can be personalized with unique designs, text, or images.

- Versatility: It works on various types of paper, from thin sheets to thicker cardstock.

- Aesthetic Appeal: The engraved effect adds a unique, elegant touch to invitations, business cards, art prints, and more.

Types of Paper Suitable for Laser Engraving

Laser engraving is a versatile technique that can be used to create detailed designs and intricate patterns on various materials, including paper. The choice of paper plays a crucial role in the quality and outcome of the engraving. Here’s a guide to the types of paper most suitable for laser engraving, along with their characteristics and ideal uses.

Cardstock

Description: Cardstock is a thick, sturdy type of paper that is more durable than regular paper but still flexible. It is often used for greeting cards, business cards, and covers.

Characteristics:

- Thickness: Usually ranges from 50 lb (135 gsm) to 110 lb (300 gsm) or more.

- Durability: Strong and resistant to tearing.

- Surface: Smooth, but available in various textures.

Ideal Uses:

- Greeting Cards: Perfect for creating personalized, high-quality cards.

- Business Cards: Durable enough to withstand frequent handling.

- Art Projects: Suitable for detailed designs and cutouts.

Laser Engraving Tips:

- Settings: Medium power and speed settings work best to prevent burning.

- Testing: Always run a test engraving to adjust settings.

Vellum

Description: Vellum is a translucent, delicate paper that adds an elegant touch to projects. It is often used for overlays in invitations and special documents.

Characteristics:

- Transparency: Semi-transparent, allowing light to pass through.

- Texture: Smooth and slightly glossy surface.

- Thickness: Typically thinner than cardstock but still sturdy.

Ideal Uses:

- Wedding Invitations: Adds a sophisticated, layered effect.

- Art Prints: Great for creating light, airy designs.

- Overlays: Used as an overlay on darker papers for contrast.

Laser Engraving Tips:

- Settings: Use low power and high speed to avoid scorching.

- Securing: Ensure the paper is flat and secure to prevent movement.

Construction Paper

Description: Construction paper is a heavyweight paper available in various colors, commonly used in crafts and school projects.

Characteristics:

- Thickness: Thicker than standard paper, around 80 lb (216 gsm).

- Color: Available in a wide range of vibrant colors.

- Texture: Slightly rough and fibrous surface.

Ideal Uses:

- Crafts: Ideal for bold, colorful projects.

- Educational Projects: Common in school art projects.

- Posters: Suitable for making decorative posters and signs.

Laser Engraving Tips:

- Settings: Medium power and speed; adjust based on color and thickness.

- Color Consideration: Darker colors may require different settings than lighter ones.

Standard Copy Paper

Description: Standard copy paper is the most common type of paper, used in everyday printing and writing.

Characteristics:

- Thickness: Generally around 20 lb (75 gsm).

- Availability: Easily accessible and inexpensive.

- Surface: Smooth and lightweight.

Ideal Uses:

- Prototypes: Good for testing designs before final engraving.

- Lightweight Projects: Suitable for temporary or disposable items.

Laser Engraving Tips:

- Settings: Use low power and high speed to avoid burning or cutting through.

- Handling: Be gentle, as the paper is more prone to tearing.

Specialty Papers

Description: Specialty papers include a wide variety of textures, finishes, and coatings that can add unique effects to your engravings.

Types:

- Textured Paper: Includes linen, felt, and other textures that add depth.

- Metallic Paper: Shiny, metallic finishes that create a striking appearance.

- Coated Paper: Glossy or matte coatings that enhance the engraved design.

Ideal Uses:

- Invitations: Adds a luxurious feel to special invitations.

- Art Prints: Perfect for creating unique, high-end art pieces.

- Product Packaging: Enhances the appearance of packaging materials.

Laser Engraving Tips:

- Settings: Adjust settings based on the specific type of specialty paper; test thoroughly.

- Handling: Be aware of the coating and texture to avoid smudging or damage.

Product Recommendation (Paid Link): ZOCONE Scratch Paper, 50 Sheets 8x11in Black Coated Scratchboard On Amazon

Preparing Your Design

Laser engraving on paper is a beautiful way to create intricate designs, personalized cards, detailed art prints, and more. The key to successful laser engraving is proper preparation of your design. Whether you’re a beginner or an experienced engraver, this guide will help you prepare your designs to achieve the best results.

Choose the Right Software

To start, you need the right software to create or modify your design. Popular graphic design programs include:

- Adobe Illustrator: Industry-standard for vector graphics and detailed designs.

- CorelDRAW: Another powerful tool for vector design, widely used in laser engraving.

- Inkscape: A free and open-source alternative that offers robust design capabilities.

- Photoshop or GIMP: For raster images, photos, and detailed bitmap designs.

Decide Between Vector and Raster

Understanding the difference between vector and raster images is crucial:

- Vector Graphics: Composed of paths defined by mathematical formulas. They are scalable without loss of quality, making them ideal for line art, logos, and text.

- Raster Images: Made up of pixels. They are best for photographs and images with complex color gradients. However, they can lose quality when resized.

For laser engraving on paper, vector graphics are generally preferred due to their precision and scalability. However, raster images can be used for detailed engravings if prepared correctly.

Create or Import Your Design

Start by creating your design or importing an existing one into your chosen software. Here are some tips for both methods:

- Creating a Design: Use the drawing tools to create shapes, lines, and text. Keep your design simple and clear for the best engraving results.

- Importing a Design: If you’re importing a design, make sure it’s high-resolution (300 DPI or higher) to avoid pixelation. Convert it to black and white if necessary.

Convert Your Design to Black and White

Laser engravers interpret designs in shades of black and white. Black areas are engraved (burned away), while white areas remain untouched. Here’s how to prepare your design:

- For Vector Designs: Ensure all lines and shapes are in black. You can adjust the stroke thickness and fill color to refine your design.

- For Raster Images: Convert your image to grayscale first, then to black and white using threshold adjustments. This helps in defining which parts of the image will be engraved.

Adjust Design Size and Resolution

Make sure your design fits within the dimensions of your paper and the working area of your laser engraver. Here’s how to adjust:

- Size: Use your software’s scaling tools to adjust the size of your design. Ensure it fits well within your paper size (e.g., A4, letter, etc.).

- Resolution: Set a high resolution (at least 300 DPI) for raster images to ensure fine details are captured accurately.

Fine-Tune the Design

Refine your design by making small adjustments:

- Simplify Details: Reduce overly intricate details that might not translate well onto paper.

- Line Weight: Ensure that lines are thick enough to be clearly engraved but not so thick that they merge together.

- Spacing: Maintain adequate spacing between design elements to prevent them from blending during engraving.

Set Up Layers (Optional)

Using layers can help you organize different elements of your design, especially if you’re combining vector and raster elements. You can:

- Separate Elements: Place text, shapes, and images on different layers for easier editing and adjustments.

- Engraving Order: Control the order in which elements are engraved by arranging layers accordingly.

Export Your Design

Once your design is ready, you need to export it in a format compatible with your laser engraver. Common formats include:

- SVG (Scalable Vector Graphics): Ideal for vector designs.

- PDF: Widely supported and preserves design quality.

- DXF (Drawing Exchange Format): Often used for CAD designs.

- PNG or BMP: For raster images, ensure they are high-resolution and in black and white.

Test Your Design

Before engraving your final piece, it’s a good idea to run a test:

- Test Material: Use a scrap piece of the same type of paper you’ll be engraving on.

- Settings: Use the same laser power, speed, and resolution settings you plan to use for the final project.

- Adjustments: Make any necessary adjustments based on the test results. This could include tweaking the design or modifying the laser settings.

Finalize Laser Settings

Set your laser engraver to the appropriate settings for paper. These typically include:

- Power: Low to medium power to avoid burning through the paper.

- Speed: High speed to ensure quick and clean engraving.

- Resolution: High resolution for detailed designs (500 DPI or more).

Refer to your laser engraver’s manual for specific settings recommendations, as they can vary between models.

Additional Tips for Success

- Clean Your Laser Engraver: Ensure your machine is clean and well-maintained to prevent dust and debris from affecting the engraving quality.

- Secure the Paper: Use tape or a vacuum table to keep the paper flat and prevent it from shifting during engraving.

- Monitor the Process: Keep an eye on the engraving process to quickly address any issues like burning or misalignment.

Common Issues and Troubleshooting

- Burning or Browning: If the laser is too powerful or slow, it can burn the paper. Reduce the power or increase the speed to avoid this.

- Incomplete Engraving: If parts of the design are missing, the laser power might be too low. Increase the power slightly.

- Paper Movement: If the paper shifts during engraving, secure it better or use a vacuum table to hold it in place.

- Design Issues: If the design isn’t coming out as expected, check your file for any errors and ensure it’s properly set up for engraving.

Applications of Laser Engraving on Paper

Laser engraving on paper can be used in various creative and practical applications:

- Greeting Cards: Create personalized, intricate designs for any occasion.

- Business Cards: Make a memorable impression with unique, engraved business cards.

- Invitations: Elegant and detailed wedding, party, or event invitations.

- Art Prints: Produce fine, detailed art prints that stand out.

- Packaging: Customize packaging materials for products or gifts.

- Labels and Tags: Design special labels or tags for products, gifts, or personal use.

- Bookmarks: Create customized, durable bookmarks as gifts or promotional items.

Advantages of Laser Engraving on Paper

- Customization: Easily personalize each piece with unique designs, names, or messages.

- Speed: Fast and efficient process, especially for bulk orders.

- Detail: Achieve high levels of detail and precision.

- Non-contact: The laser doesn’t physically touch the paper, reducing the risk of damage.

Safety Considerations

While laser engraving on paper is generally safe, there are some precautions to keep in mind:

- Ventilation: Ensure proper ventilation in your workspace to avoid inhaling any fumes or smoke produced during engraving.

- Eye Protection: Always wear appropriate eye protection to prevent exposure to the laser beam.

- Fire Hazard: Paper is flammable, so always monitor the engraving process to quickly address any signs of burning.

Our Buying Guides Can Be Found Here:

Top 5 Laser Engraver Exhaust Fan Options: Best Quality!

Best Fume Extractors for Laser Engravers: 5 Quality Options!

Laser Engraver Enclosure Options: You Need The Best Quality

Laser Engraving Eye Protection – Most Important Information

Tips for Successful Laser Engraving on Paper

- Experiment with Settings: Different papers may require different settings. Don’t be afraid to experiment until you find the perfect combination.

- High-Quality Designs: Use high-resolution images and clean vector graphics for the best results.

- Proper Maintenance: Keep your laser engraver clean and well-maintained to ensure consistent performance.

- Batch Processing: If engraving multiple pieces, set up batch processing to save time and maintain consistency.

Conclusion

Laser engraving on paper is a versatile and exciting technique that allows you to create beautiful, detailed designs with precision and ease. Whether you’re making personalized greeting cards, unique business cards, or elegant invitations, understanding the basics of laser engraving on paper can help you achieve stunning results.

By selecting the right paper, preparing your design properly, setting up your laser engraver correctly, and following safety guidelines, you can unlock a world of creative possibilities. Experiment with different settings and designs to discover what works best for your projects, and enjoy the art of laser engraving on paper.