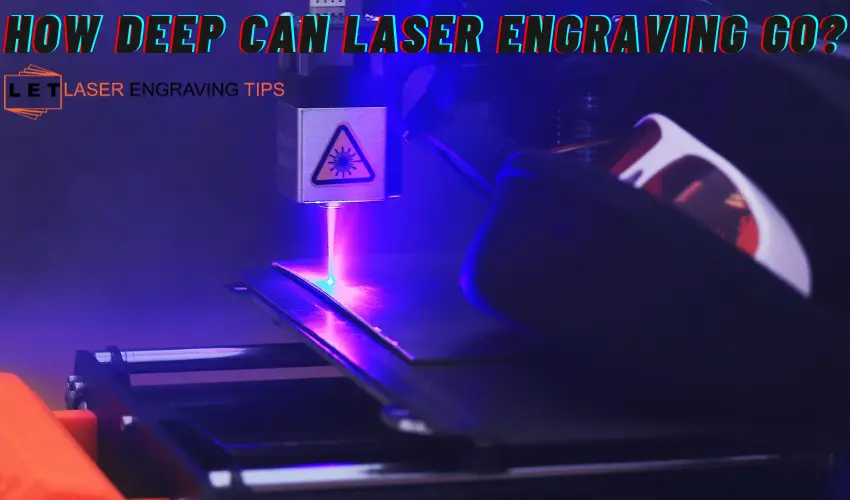

Laser engraving is a popular technique used to create detailed and permanent marks on a wide variety of materials, including metals, plastics, wood, and glass. The depth of laser engraving can vary significantly based on several factors, including the type of laser used, the material being engraved, and the specific settings and techniques applied. This article explores how deep laser engraving can go and what influences this depth.

Table of Contents

So how deep can laser engraving go?

Practical Depth Achievements

- Metals:

- Stainless Steel: Depths of 1-2mm with a fiber laser.

- Aluminum: Depths of up to 1.5mm with a fiber laser.

- Brass and Copper: Slightly less depth than steel due to their higher reflectivity.

- Non-Metal Materials:

- Wood: Depths of 2-5mm or more with a CO2 laser.

- Acrylic: Typically 1-2mm with a CO2 laser.

- Leather: Depths of 0.5-1.5mm with a CO2 laser.

- Glass and Ceramics: Generally shallow, up to 1mm with a CO2 laser.

Factors Affecting Engraving Depth

- Type of Laser

- Fiber Lasers: Typically used for metals and hard plastics, fiber lasers can achieve greater depths due to their higher power density and smaller spot size. They are capable of deep engraving on metals such as stainless steel, aluminum, and titanium, often reaching depths of up to 2mm or more.

- CO2 Lasers: More commonly used for non-metal materials like wood, acrylic, leather, and glass. CO2 lasers generally achieve shallower engravings compared to fiber lasers, with typical depths ranging from 0.5mm to 1.5mm on these materials.

- Diode Lasers: Generally less powerful than fiber and CO2 lasers, diode lasers are more suited for surface marking and shallow engravings, typically up to 0.5mm deep.

- Material Being Engraved

- Metals: Harder materials like metals require more energy to engrave deeply. Fiber lasers are ideal for metals, achieving depths of up to 2mm or more depending on the power and settings.

- Wood: Softer materials like wood can be deeply engraved with a CO2 laser. The depth can vary from a few millimeters to over 5mm, depending on the wood type and laser power.

- Plastics: Depth varies widely with plastic types. Softer plastics can be engraved up to 1mm deep with a CO2 laser, while harder plastics might require fiber lasers for deeper engraving.

- Glass and Ceramics: Generally, laser engraving on glass and ceramics results in shallow depths, usually not exceeding 1mm, as these materials are brittle and prone to cracking under intense laser heat.

- Laser Power and Speed

- Power Output: Higher power lasers can engrave deeper by delivering more energy to the material. For example, a 50W fiber laser will engrave deeper than a 20W laser given the same material and settings.

- Engraving Speed: Slower engraving speeds allow the laser to dwell longer on the material, removing more material per pass and thus achieving greater depths.

- Number of Passes

- Multiple Passes: Performing multiple passes over the same area can increase the engraving depth. Each pass removes additional material, gradually deepening the engraving.

- Focus and Lens

- Proper Focus: Ensuring the laser is properly focused on the material is crucial. A well-focused laser beam delivers maximum energy density, which is essential for deeper engraving.

- Lens Type: The type of lens used can affect the spot size and energy delivery, influencing the engraving depth. Smaller focal length lenses concentrate the laser energy into a smaller spot, increasing engraving depth.

Also Read: How Small Can You Laser Engrave?

How to Increase the Depth of Laser Engraving

Laser engraving is a versatile technique used to create detailed and permanent marks on various materials. Sometimes, specific applications require deeper engravings for enhanced durability, visibility, or functionality. Increasing the depth of laser engraving involves adjusting several factors related to the laser engraver’s settings, the material being engraved, and the engraving process itself. Here’s a guide on how to achieve deeper laser engravings.

1. Adjust Laser Power

Increase Laser Power:

- Higher Power Output: The most direct way to achieve deeper engravings is by increasing the laser power. Higher power increases the energy delivered to the material, allowing the laser to remove more material in each pass.

- Machine Specifications: Ensure your laser engraver supports the power level needed for deeper engraving. Some machines might have a maximum power limit that restricts how deep they can engrave.

2. Reduce Engraving Speed

Slower Speed for Deeper Cuts:

- Lower Speed Setting: Reducing the engraving speed allows the laser to spend more time on each point, which increases the amount of material removed.

- Balancing Speed and Power: A combination of higher power and slower speed can significantly increase the engraving depth but requires careful calibration to avoid damaging the material.

3. Increase the Number of Passes

Multiple Passes Technique:

- Repeated Engraving: Running multiple passes over the same area can gradually increase the depth of the engraving. Each pass removes a thin layer of material, allowing for controlled and precise deepening of the engraving.

- Cooling Periods: Allow the material to cool between passes to prevent overheating, which can affect the quality and consistency of the engraving.

4. Optimize Focus and Lens

Adjust Focus for Maximum Precision:

- Proper Focus: Ensuring the laser beam is properly focused on the material surface is crucial. The focal point should be as small as possible to concentrate the laser’s energy effectively.

- Adjustable Lenses: Some laser engravers come with adjustable lenses. Experiment with different focal lengths to find the optimal setting for deeper engraving.

5. Use Appropriate Materials

Material Selection:

- Material Properties: Different materials respond differently to laser engraving. Softer metals like aluminum or materials like acrylic might allow for deeper engravings more easily than harder metals like stainless steel.

- Pre-Treatment: Some materials can be treated or coated to enhance their engravability, making it easier to achieve deeper marks.

Best Materials For Laser Engraving Buying Guide

6. Utilize Pulse Settings

Pulse Frequency and Duration:

- Pulse Settings: Adjusting the pulse frequency and duration can influence the depth of engraving. Shorter, more intense pulses can create deeper engravings, especially on metals.

- Pulse Mode: Some laser engravers allow you to switch between continuous wave (CW) and pulsed modes. Pulsed modes are often better for deeper engravings as they concentrate more energy into each pulse.

7. Consider Assisted Gas

Gas Assistance:

- Air Assist: Using an air assist system can help blow away debris from the engraving area, allowing the laser to maintain its focus and efficiency.

- Inert Gases: For certain materials, using inert gases like nitrogen or argon can help achieve cleaner and deeper engravings by reducing oxidation and assisting in material removal.

8. Software Settings

Optimize Software Parameters:

- Engraving Parameters: Many laser engraving machines come with software that allows for detailed control over engraving parameters. Adjust settings like laser intensity, pass count, and line spacing for deeper engraving.

- Advanced Features: Some advanced software offers features like 3D engraving, where the software automatically adjusts power and speed to create deeper cuts at specific points in the design.

9. Cooling and Cleaning

Maintain Temperature and Cleanliness:

- Cooling System: Ensure your laser engraver has an adequate cooling system to prevent overheating, which can affect the depth and quality of the engraving.

- Clean Workspace: Regularly clean the lens and mirrors of your laser engraver to ensure maximum efficiency and power delivery.

10. Experimentation and Testing

Trial and Error:

- Test Runs: Perform test engravings on scrap material to fine-tune your settings without risking the final product.

- Documentation: Keep a log of successful settings for different materials and depths, which can serve as a reference for future projects.

Increasing the depth of laser engraving involves a combination of adjusting machine settings, selecting appropriate materials, and using proper techniques. By optimizing laser power, speed, focus, and other parameters, you can achieve deeper and more precise engravings. Regular experimentation and careful documentation of your settings will help you refine your process and produce consistent, high-quality results. Whether you’re engraving for industrial applications, artistic projects, or personal use, these tips will enhance your ability to create deep and durable engravings.

How Deep Can Fiber Laser Engraving Go?

Fiber laser engraving is a powerful and precise method used to mark, etch, and engrave a variety of materials, particularly metals and hard plastics. The depth of engraving that can be achieved with a fiber laser depends on several factors, including the laser’s power, the material being engraved, the engraving speed, and the number of passes. This guide explores the depths fiber laser engraving can reach and the factors influencing these depths.

Factors Influencing Engraving Depth

- Laser Power

- Higher Power: Higher wattage fiber lasers (e.g., 50W, 100W) can engrave deeper than lower wattage lasers (e.g., 20W, 30W). More power means more energy is directed at the material, allowing for greater penetration.

- Continuous vs. Pulsed Power: Pulsed fiber lasers, which deliver short, high-energy bursts, can achieve deeper engravings than continuous wave lasers for certain materials by concentrating energy more effectively.

- Material Type

- Metals: Metals such as stainless steel, aluminum, brass, and titanium can be deeply engraved with fiber lasers. The hardness and thermal conductivity of the metal affect how deep the laser can engrave.

- Hard Plastics: Certain hard plastics, such as Acetyl and ABS, can also be deeply engraved, though typically not as deep as metals.

- Other Materials: Fiber lasers are generally less effective on non-metal materials like wood, glass, and organic substances, which are better suited for CO2 lasers.

- Engraving Speed

- Slower Speeds: Reducing the speed of the laser allows it to spend more time on each point, increasing the depth of penetration.

- Balance: There needs to be a balance between speed and power to prevent material damage or excessive burning.

- Number of Passes

- Multiple Passes: Performing multiple passes over the same area can gradually increase the depth of engraving. Each pass removes a layer of material, building up the depth incrementally.

- Cooling Intervals: Allowing the material to cool between passes can prevent overheating and warping, leading to more precise engravings.

- Focus and Lens

- Proper Focus: Ensuring the laser beam is properly focused on the material surface is crucial. The focal point should be as small as possible to maximize energy concentration.

- Lens Type: The choice of lens affects the spot size and energy delivery, influencing the depth. Shorter focal length lenses can focus the laser energy more tightly, achieving deeper engravings.

Practical Depth Achievements

Metals

- Stainless Steel: Fiber lasers can achieve engraving depths of up to 2mm or more on stainless steel with high power settings and multiple passes.

- Aluminum: Due to its softer nature, aluminum can be deeply engraved, often reaching depths of 1.5mm to 2mm.

- Brass and Copper: These metals, while reflective, can still be deeply engraved with fiber lasers, achieving depths similar to aluminum.

Hard Plastics

- Acetyl and ABS: Fiber lasers can engrave these materials up to 1mm to 1.5mm deep, depending on the power and number of passes.

Enhancing Engraving Depth

- Increase Laser Power

- Use the highest power setting that your laser engraver allows, appropriate for the material you are working with.

- Consider upgrading to a higher wattage fiber laser if deeper engravings are regularly required.

- Optimize Engraving Speed

- Reduce the engraving speed to allow the laser more time to penetrate the material.

- Experiment with different speed settings to find the optimal balance for your specific material.

- Multiple Passes

- Plan for multiple passes to achieve the desired depth. Keep a consistent focus and ensure the material remains stable throughout the process.

- Allow the material to cool between passes to prevent overheating.

- Proper Focus and Lens Selection

- Regularly check and adjust the focus of the laser beam to maintain maximum energy concentration.

- Use lenses that provide the smallest spot size for deeper engraving.

- Material Preparation

- Clean the material surface before engraving to remove any contaminants that could interfere with the laser’s effectiveness.

- Consider pre-treating the material with coatings or treatments that enhance laser absorption.

Fiber laser engraving can achieve significant depths, particularly on metals and hard plastics. The depth of engraving is influenced by laser power, material type, engraving speed, the number of passes, and proper focus. By optimizing these factors, fiber lasers can achieve depths of up to 2mm or more on metals and up to 1.5mm on certain plastics. Whether for industrial applications, personalized items, or intricate designs, understanding how to control and maximize engraving depth with a fiber laser opens up a world of possibilities for detailed and durable engravings.

Conclusion

The depth of laser engraving depends on various factors including the type of laser, the material, and the settings used. Fiber lasers are typically more effective for deeper engravings on metals, while CO2 lasers excel with non-metal materials. By adjusting laser power, speed, focus, and the number of passes, you can achieve the desired engraving depth for your specific application. Whether you need shallow markings or deep engravings, understanding these variables will help you maximize the capabilities of your laser engraving machine.