This article explains the key differences between laser cutting and laser engraving, two popular laser-based techniques used in various industries. It covers how laser cutting precisely slices through materials to create shapes, while laser engraving alters the surface to add designs or text.

Additionally, the article highlights the materials each method works with, their applications, and the benefits of using these technologies for detailed and efficient production.

Table of Contents

What is laser cutting and laser engraving?

Laser cutting and laser engraving are two widely used processes that harness the precision and power of laser technology to manipulate materials. While they share similarities, their purposes and outcomes differ significantly. Here’s a closer look at each:

What is Laser Cutting?

Laser cutting is a process that uses a focused, high-powered laser beam to cut materials into specific shapes or designs. The laser’s heat vaporizes or melts the material, creating clean, precise cuts. This method is highly versatile and is used to cut a wide range of materials, including:

- Metals (steel, aluminum, copper)

- Wood

- Acrylic

- Plastics

- Textiles

Laser cutting is favored in industries such as manufacturing, automotive, aerospace, and even in small businesses for custom projects. The level of detail and accuracy achievable with laser cutting surpasses many traditional cutting methods, making it ideal for complex designs and intricate cuts.

What is Laser Engraving?

Laser engraving, on the other hand, involves using a laser to remove or vaporize the surface layer of a material to create a design or mark. Unlike laser cutting, which goes through the material, laser engraving is a surface-level process. The laser’s heat causes the material to change color or texture, leaving a permanent design, image, or text. Commonly engraved materials include:

- Wood

- Glass

- Metal

- Plastic

- Leather

Laser engraving is frequently used for creating personalized products, signage, awards, and even industrial parts that require serial numbers or barcodes. The precision of laser engraving makes it an ideal choice for fine detailing, logos, or custom artwork.

Differences Between Laser Cutting and Laser Engraving

- Depth: Laser cutting slices through materials, while laser engraving alters the surface.

- Purpose: Laser cutting is for producing shapes and parts, while engraving is for marking or adding designs.

- Material Use: Both can be used on similar materials, but engraving tends to leave the material intact, while cutting removes portions of it.

How does the laser cutter and laser engraver work?

Laser cutters and laser engravers are powerful tools that use focused beams of light to manipulate materials with high precision. While both machines rely on laser technology, they serve different purposes: laser cutters slice through materials, while laser engravers etch designs or text on the surface. Here’s a breakdown of how each works.

Laser Cutter

A laser cutter uses a concentrated beam of light to cut through various materials, such as wood, acrylic, metal, or fabric. The process starts by generating a laser beam using a laser source, such as a CO2 or fiber laser. This beam is directed through a series of mirrors and lenses to focus the light on a specific spot, achieving extreme precision.

- How It Works: The material is placed on a cutting bed, and the laser beam moves according to the programmed design. The intense heat from the laser vaporizes or melts the material, creating clean, sharp cuts. Depending on the power of the laser and the material, the beam can cut completely through or create intricate designs.

- Materials: Different types of lasers can cut a variety of materials. CO2 lasers are excellent for cutting non-metal materials like wood, leather, and acrylic, while fiber lasers are used for metals.

Laser cutters may be built in a similar way but they are different because each is built with a unique power range. This means that different laser cutters are ideal for different types of materials and thicknesses. There are three main categories of laser cutters with unique characteristics and functions. The table below illustrates this more clearly;

Laser cutter type | Mode of operation | Characteristics | Materials to use |

CO2 Laser

| A gas that is a mixture of carbon dioxide and nitrogen with hydrogen with either xenon or helium | Inexpensive laser cutter and it can cut thin sheets | Wood, plastics, leather, foams, and acrylic |

Fiber lasers

| The laser beam is amplified through glass fibers | Commonly used for placing logos on products, making custom products and barcoding. | Metals and plastics |

Neodymium lasers

| Uses neodymium-doped crystals | They have a small wavelength which allows them to cut through thick materials | Metals, plastic, and ceramics |

Laser Engraver

A laser engraver operates similarly to a laser cutter but focuses on altering the surface of the material rather than cutting through it. The engraver uses a lower-power laser beam to mark the surface by burning, melting, or etching, creating text, logos, or images.

- How It Works: The laser engraver follows a programmed pattern to etch the surface of the material. The intensity and duration of the laser beam can be adjusted to control the depth and detail of the engraving. Laser engraving doesn’t penetrate the material deeply, but it leaves a permanent mark.

- Materials: Laser engravers can work on a wide range of materials, including wood, metal, glass, leather, and plastic. CO2 lasers are commonly used for non-metal materials, while fiber lasers are preferred for metals.

Key Components in Both Machines:

- Laser Source: The type of laser (CO2, fiber, diode) determines the materials the machine can process.

- Optics System: Mirrors and lenses focus and direct the laser beam.

- Control Software: Designs are programmed into the system via CAD or design software, dictating the movement and behavior of the laser.

- Cooling System: As lasers generate significant heat, cooling mechanisms prevent overheating.

Applications

- Laser Cutters: Used in industries for creating prototypes, cutting fabrics, woodworking, metal fabrication, and creating parts for machinery.

- Laser Engravers: Commonly used for personalization, marking parts with serial numbers, creating signs, and engraving trophies or awards.

Check out our buying guide: Best Laser Engraver for small business

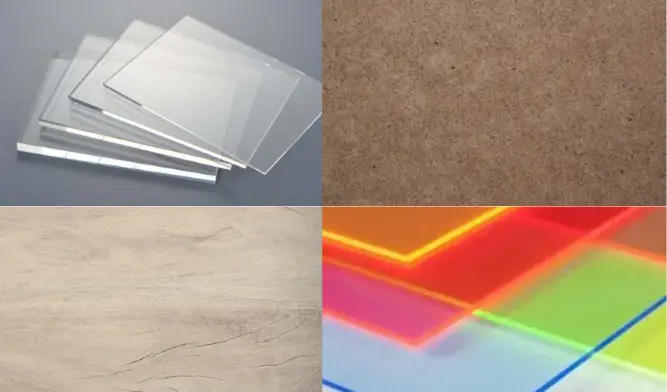

Materials ideal for laser cutting and laser engraving

Laser cutting and engraving are incredibly versatile techniques used across many industries, from manufacturing to crafting. Choosing the right material for laser cutting and engraving can make a big difference in achieving the best results. Here’s a guide to the materials that are ideal for these processes, broken down into categories based on the type of laser used and material properties.

Wood

Wood is one of the most popular materials for both laser cutting and engraving due to its natural aesthetic and ease of use.

- Laser Cutting: Wood can be cut with precision using a CO2 laser. It’s ideal for creating detailed designs, custom furniture pieces, signs, and prototypes.

- Laser Engraving: Wood responds well to engraving, creating deep, dark marks on the surface. Different types of wood, such as plywood, MDF, and hardwood, can be engraved with intricate patterns.

- Examples: Birch plywood, MDF, bamboo, oak, cherry.

Caution: Some laser materials including wood are highly flammable. You should, therefore, keep a close eye during the cutting process to avoid accidents. Always a good idea to keep a fire extinguisher handy for any sudden flare ups. We use the First Alert Professional Fire Extinguisher in our workshop. More information can be found here.

Acrylic and Plastics

Acrylic, also known as Plexiglass, is widely used for both cutting and engraving due to its clean cutting properties.

- Laser Cutting: Acrylic can be cut into precise shapes with a smooth, polished edge, making it perfect for signage, display cases, and artistic projects.

- Laser Engraving: Engraving on acrylic creates a frosted effect, often used for awards, plaques, and decorative items.

- Examples: Cast acrylic, extruded acrylic, polycarbonate (for engraving), and certain other plastics.

Metals

While metals are typically used with fiber lasers or a CO2 laser with special coatings, they are ideal for industrial applications and detailed engravings.

- Laser Cutting: Metals like steel, aluminum, and brass are commonly laser cut for manufacturing and industrial parts. The high precision and clean cuts make metal laser cutting essential for custom metalwork.

- Laser Engraving: Metals can be engraved with barcodes, serial numbers, logos, and custom designs. Pretreatments such as marking sprays are often needed for CO2 lasers, but fiber lasers can engrave metals directly.

- Examples: Stainless steel, anodized aluminum, brass, titanium, and copper.

Glass

Glass can’t be laser cut, but it is an excellent material for engraving.

- Laser Engraving: When engraved, glass creates a frosted look, ideal for customizing glassware, mirrors, and awards. CO2 lasers are often used, and masking or special coatings can help create cleaner lines.

- Examples: Windows, drinking glasses, mirrors.

Leather

Leather is another material well-suited for both cutting and engraving, offering a rich texture and durable finish.

- Laser Cutting: Leather can be cut into custom shapes for fashion items, accessories, and upholstery. Laser cutting provides a clean edge without fraying.

- Laser Engraving: Engraving on leather adds personalization to wallets, belts, bags, and shoes. It creates a textured surface that enhances the material’s natural look.

- Examples: Full-grain leather, synthetic leather, suede.

Paper and Cardboard

Paper and cardboard are ideal for precision cutting and engraving, often used for packaging, invitations, and craft projects.

- Laser Cutting: The laser’s accuracy allows for highly detailed cuts in paper, perfect for custom cards, packaging designs, and prototypes.

- Laser Engraving: While engraving on paper or cardboard is typically shallow, it can be used to add intricate details to invitations or labels.

- Examples: Cardstock, corrugated cardboard, chipboard, craft paper.

Rubber

Laser cutting and engraving on rubber are often used to create custom stamps, seals, and gaskets.

- Laser Cutting: The laser allows precise cutting of custom designs and shapes for industrial gaskets or artistic rubber pieces.

- Laser Engraving: Rubber is primarily engraved for stamp-making, where the laser carves out detailed, durable impressions.

- Examples: Natural rubber, silicone rubber, EPDM.

Fabric and Textiles

Textiles such as cotton, polyester, and felt can be laser cut and engraved for fashion, home décor, and craft purposes.

- Laser Cutting: The laser’s ability to create clean, sealed edges on fabric makes it perfect for cutting patterns for clothing, curtains, and upholstery.

- Laser Engraving: Fabric engraving adds a unique touch to garments, accessories, and even artworks by burning patterns or logos into the fabric.

- Examples: Denim, felt, silk, polyester, cotton.

Stone and Ceramics

Stone and ceramics are not suitable for cutting but are excellent for laser engraving, especially in crafting and industrial design.

- Laser Engraving: Stone engraving creates deep, permanent markings perfect for decorative items, awards, and memorial plaques. Ceramic engraving adds custom designs to tiles, mugs, and other household items.

- Examples: Granite, marble, porcelain, slate, and ceramic tiles.

Foam

Foam is a highly versatile material for laser cutting, commonly used in packaging, insulation, and cushioning products.

- Laser Cutting: Foam is easy to cut and can be shaped into custom inserts for cases or protective packaging. The laser ensures precision and clean edges.

- Examples: EVA foam, polyethylene foam, polyurethane foam.

Laser cutting and engraving are highly adaptable technologies that can be used on a wide variety of materials, from metals and wood to leather and acrylic. Understanding the properties of each material and choosing the right laser system (CO2 or fiber) is key to getting the best results, whether you’re crafting, personalizing, or manufacturing items.

Final Thoughts

Both laser cutting and laser engraving are invaluable techniques in modern industries, offering high precision, efficiency, and versatility for a variety of projects. Whether you’re looking to create intricate cuts for products or engrave detailed designs, these laser technologies open up endless possibilities for customization and manufacturing.