Cutting and engraving wood can be a great way to bring your vision for your projects to life. However, cutting wood by hand can be difficult and time-consuming. Laser-cutting wood solves this problem by providing an effortless way to get precise cuts every time but you need to prepare wood for laser cutting.

Table of Contents

That said, it’s essential to understand the basics before attempting to laser cut your wood, including determining the best wood for laser cutting and the best way to prepare it. If you need some tips for wood laser cutting, you’ve come to the right place. Keep reading to learn the best practices for handling wood for laser cutting.

What Is Laser Cutting?

Laser cutting is a method of making precise cuts on flat materials, including wood. Laser cutting can also work for materials such as acrylic and leather. These precise cuts are achieved by using a laser-cutting machine.

A wood laser cutter is used to cut, mark, and engrave your chosen material. Laser cutters emit a concentrated beam of light through the laser cutter’s head onto the material.

Most 100 Watt CO2 laser cutters can cut wood between 0.5 – 15 mm thick. Anything thicker will require multiple passes and won’t result in the clean cut you seek. For detailed information you can also read the article I wrote on what can a 100W laser cut.

While there are several types of laser machine cutters, the most common ones used by enthusiasts are CO2 lasers and Diode lasers. CO2 lasers are particularly popular, especially for cutting wood.

How To Prepare Wood For Laser Cutting

Step 1: Choose The Best Type of Wood For Laser Cutting

Since wood is a natural material, you have to consider the characteristics of the type of wood that you’re using before preparing it for laser cutting. Some natural wood will deliver better results for your needs than others, and some woods you shouldn’t use at all.

Consider the following types of popular wood for laser cutting:

- Soft wood: Can be cut at a quicker speed, and if engraving then this will result in a lighter engraving

- Hard wood: Needs to be cut with a higher laser power than soft wood

- Plywood: Made from at least three layers of wood glued together. The type of glue determines how you would prep this wood material.

Choosing a thinner, low-density wood for laser cutting is best. As mentioned, anything too thick may not result in a precise cut.

The most popular woods for laser cutting include balsa, basswood, poplar, alder, cedar, oak, walnut, mahogany, cherry, maple, birch, pine, cork, MDF and plywood.

Best Wood For Laser Cutting & Engraving

Explore the top wood options for laser engraving below, tested and proven by Laser Engraving Tips to deliver clean and precise results.

Image |

Product |

Details |

Price |

|---|---|---|---|

|

MDF Sheets |

Thickness: 3mm (1/8″) Size: 12 x 12″ Sheets Quantity: 20 |

|

|

Baltic Birch Plywood |

Thickness: 3mm (1/8″) Sizes: 6 x 6″, 6 x 12″, 8 x 8″, 10 x 10″, 12 x 8″, 12 x 9″ Quantity: 8 / 12 / 16 / 25 / 45 / 50 / 100 |

|

|

Basswood Sheets |

Thickness: 3mm (1/8″) Size: 12 x 12″ Sheets Quantity: 18 / 30 / 42 |

Now, let’s talk about the nest step which is creating your design for laser cutting.

Step 2: Create Your Design

The second step is to design the object you want to cut using your preferred CAD software. Some of the most popular software used for laser cutting include the following:

Make sure to use multiple levels of cut lines when designing. This will make it easier to arrange the layers later when you transfer the design into CAM software. There are various free and paid laser engraving and cutting software options available for CAD, CAM, and control operations.

Step 3: Clean and Smooth the Surface

When preparing your wood for laser cutting, the first thing you want to check is whether the wood fits into the work area of the laser cutter. If not, you must cut it down to the necessary size and sand it to remove any sharp edges.

Additionally, the wood needs to be free of knots and any other flaws that can lead to uneven cutting. Before beginning to cut, the wood’s surface should be well cleaned and dry because oil or dirt will obstruct the cutting process.

- Sand the Wood: Use 200-300 grit sandpaper to smooth the surface. This ensures a uniform engraving and reduces residue from laser burns.

- Remove Dust: After sanding, wipe the wood with a clean, damp cloth to remove debris that could interfere with the laser.

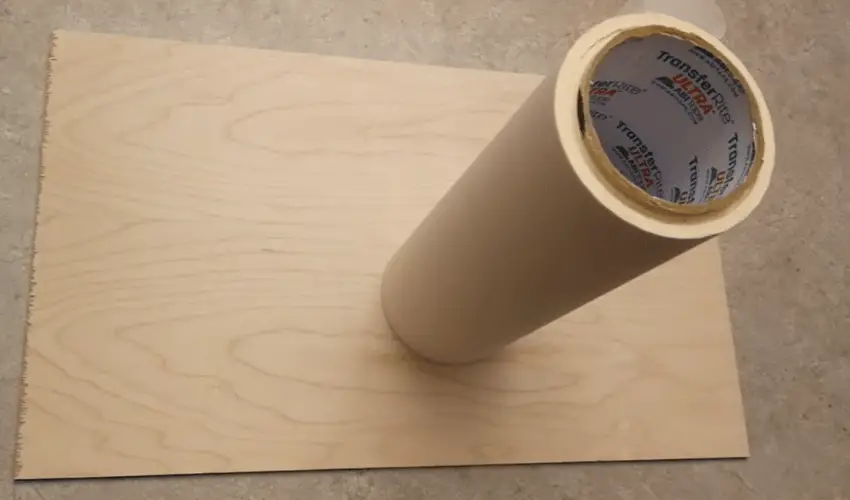

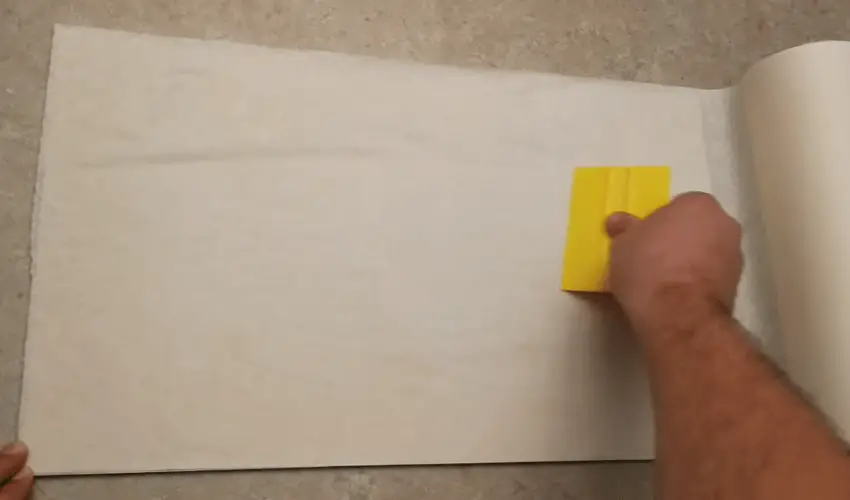

Step 4: Transfer Tape Application

To prevent burn marks use transfer tape which is available in a ready-made wide roll and works wonderfully with a laser cutter, the tape can be tacked to the wood’s surface. For a flawless finish, you can use the tape on both sides of your wood. The tape should be firmly pressed down with the help of a small plastic squeegee to remove any air bubbles that could interfere with the cutting operation.

The Transfer Tape We Recommend

Step 5: Secure the Wood

Place the wood flat on the laser bed, ensuring it’s stable and properly aligned.

- Ensure the wood lies flush to avoid uneven cutting.

- For thin sheets, use weights or clamps to prevent warping.

Step 6: Preparing Your Laser Cutter

The most important settings for you to know on your laser cutter are speed, power, frequency, and focus. As you can guess, the speed determines how fast the laser can cut. The thinner the wood, the higher the speed should be set.

The type of wood and its thickness determine the ideal laser settings.

- Power: Higher power for hardwood, lower for softwood.

- Speed: Adjust to balance between clean cuts and avoiding burns.

- Focus: Ensure the laser beam is correctly focused for precision.

Running Test Cuts

It is preferable to test how a laser cutter cuts the wood you intend to use. To determine the best parameters for your test run, use the below laser cutting thickness and speed chart as a reference. In general, start with the lowest recommended setting and gradually work your way up until you achieve the best results. You can avoid wasting material by using the correct laser settings.

Diode Laser Cutter Thickness & Speed Chart for Wood

Wood Thickness | Laser Power (W) | Speed (mm/min) | Passes | Notes |

|---|---|---|---|---|

1mm (0.04″) | 10W | 600-800 | 1 | Suitable for engraving and fine cutting. |

2mm (0.08″) | 10W | 400-600 | 1-2 | Reduce speed for cleaner cuts. |

3mm (0.12″) | 10W | 300-500 | 2 | Use air assist to minimize charring. |

4mm (0.16″) | 10W | 250-400 | 2-3 | May require higher laser power for hardwoods. |

5mm (0.20″) | 10W | 200-350 | 3-4 | Optimal for softwoods; slower for hardwoods. |

6mm (0.24″) | 10W | 150-300 | 4-5 | Multiple passes needed; ensure proper cooling. |

Tips for Using the Chart

- Test First: Always perform a test cut on a scrap piece of the same wood to refine the settings.

- Adjust Air Assist: Use air assist to blow away smoke and debris, reducing charring and improving cutting quality.

- Watch for Burn Marks: For thicker wood, slow speed or multiple passes can increase the chance of burns. Use protective transfer tape to mitigate this.

- Cooling Period: Allow the laser and material to cool between passes to avoid overheating and warping.

- Fine-Tune Focus: Ensure the laser beam is perfectly focused for maximum efficiency, especially on thicker materials.

This chart is a starting point—specific settings can vary based on the diode laser model, wood type, and environmental conditions.

CO2 Laser Cutter Thickness & Speed Chart for Wood

Wood Thickness | Laser Power (W) | Speed (mm/sec) | Passes | Notes |

|---|---|---|---|---|

1mm (0.04″) | 40-50W | 30-40 | 1 | Fast and clean; suitable for engraving or thin sheet cutting. |

2mm (0.08″) | 40-50W | 25-35 | 1 | Light woods (e.g., pine) cut faster; hardwoods may require slower speeds. |

3mm (0.12″) | 40-60W | 20-30 | 1 | Use air assist to minimize charring and ensure smooth edges. |

4mm (0.16″) | 50-60W | 15-25 | 1 | Slower speed ensures precision, especially for hardwoods. |

5mm (0.20″) | 60W+ | 10-20 | 1-2 | May require multiple passes for denser wood types. |

6mm (0.24″) | 60W+ | 8-15 | 1-2 | Ensure proper focus; air assist highly recommended. |

10mm (0.39″) | 80W+ | 5-10 | 2-3 | Slower speeds and additional passes needed for cleaner cuts. |

12mm (0.47″) | 100W+ | 4-8 | 2-4 | Hardwoods may require adjustments to power or multiple passes. |

Best Practices

- Test Cuts: Always perform a small test on scrap wood to fine-tune settings.

- Air Assist: Use air assist to reduce burn marks and remove debris from the cutting path.

- Transfer Tape: Apply transfer tape to protect the surface and minimize scorching.

- Adjust Focus: Ensure the laser beam is correctly focused for optimal performance.

- Cooling Time: Allow the material to cool between passes to prevent warping or excessive burning.

- Material-Specific Settings: Softwoods like pine cut faster than hardwoods like oak or walnut.

This chart is a starting point, and adjustments may be needed based on the specific CO2 laser cutter model, lens focal length, and material condition. Always prioritize safety and proper ventilation when laser cutting wood.

Finally, if the results of your laser cutting tests do not match your expectations, take the time to change the speed and power settings and retest. Check the edges of your cuts. If there are no rough or jagged edges, your settings are correct, and if there are, you need to either increase power or decrease speed.

Set The Laser Frequency

In contrast, the frequency – measured in Hz – determines the number of laser pulses per second. Wood typically cuts best on a CO2 Laser with a lower frequency of 1000 Hz.

Set The Focus

Finally, the focusing lens in the laser head is used for precision. The focus point should be set on the material surface. Smooth cuts on wood can be achieved with a lens of 2″ focal length and a small laser spot size of 0.001″. The depth of focus of a lens with a long focal length is greater than that of a lens with a shorter focal length, a lens with a long focal length is the best choice for cutting thicker pieces of wood.

Use an Exhaust System & Air Assist

Using a laser to cut wood produces a lot of smoke and fumes which will obstruct the laser’s path, lower its intensity, and result in uneven cutting. As a result, it’s important to use an exhaust system, fume extractor or laser enclosure along with high-pressure air assist to remove the smoke from the work area.

The air assist with a high-pressure air compressor and the exhaust system will lessen the impact of charring. A honeycomb table can also be used to lessen charring.

Detailed Information can be found in our buying guides: Top 5 Laser Exhaust Fan Options Top 5 Best Fume Extractors for Laser Laser Engraver Enclosure Options Best Honeycomb Laser Bed

Once you have this setup, it’s finally time to cut!

Step 7: Post-Cutting Cleanup

- Clean Residue: Use a damp cloth or alcohol wipes to remove soot or residue from the edges and surface.

- Remove Protective Tape: Peel off any masking tape carefully.

Safety precautions when laser cutting wood

Laser cutting wood is a popular technique for creating intricate designs and precise cuts in woodworking projects. While the process is efficient and produces excellent results, it also poses safety risks if not handled correctly. Below, we outline the essential safety precautions you should take when laser cutting wood to ensure a safe working environment.

Ensure Proper Ventilation

- Why: Laser cutting generates smoke and fumes, which can be harmful if inhaled.

- Precaution: Use an exhaust system or an air filtration unit to remove smoke and maintain air quality. Position your laser cutter in a well-ventilated area.

Wear Appropriate Personal Protective Equipment (PPE)

- Why: Laser light, wood particles, and fumes can pose health risks.

- Precaution:

- Wear safety goggles rated for laser protection.

- Use a mask or respirator to avoid inhaling fine particles and toxic fumes.

- Gloves may be necessary when handling hot or sharp pieces of wood post-cutting.

Check the Wood for Coatings

- Why: Treated or painted wood can release toxic fumes when laser-cut.

- Precaution: Use only untreated, natural wood. If you must use coated wood, confirm that it is safe for laser cutting and ensure proper ventilation.

Maintain a Clean Workspace

- Why: Dust and debris can ignite, increasing the risk of fire.

- Precaution: Regularly clean the laser cutter bed and surrounding workspace to remove wood dust and leftover scraps.

Inspect and Maintain the Laser Cutter

- Why: Faulty equipment can lead to accidents or fires.

- Precaution:

- Regularly inspect the laser cutter for damage or wear.

- Clean the optics and replace worn-out parts to ensure efficiency and safety.

Use Fire Safety Equipment

- Why: Wood is flammable, and laser cutting can generate enough heat to ignite it.

- Precaution:

- Keep a fire extinguisher (Class A for wood fires) nearby.

- Never leave the laser cutter unattended while in use.

Adjust Laser Settings Correctly

- Why: Excessive power or speed settings can cause burning or fire.

- Precaution: Use recommended power and speed settings for the specific type and thickness of wood you’re cutting. Test on a scrap piece first.

Avoid Direct Contact with the Laser Beam

- Why: The laser beam can cause severe burns or injuries.

- Precaution: Never place your hands or any body part near the laser beam. Ensure that the laser cutter’s safety enclosure is intact and operational.

Monitor for Overheating

- Why: Prolonged operation can cause the laser cutter to overheat, increasing fire risk.

- Precaution: Take breaks during extended cutting sessions to let the machine cool down. Monitor its temperature throughout.

Follow Manufacturer’s Guidelines

- Why: Each laser cutter has specific safety protocols.

- Precaution: Read and adhere to the user manual and manufacturer’s recommendations for your specific laser cutter model.

Safety should always be a priority when laser cutting wood. By ensuring proper ventilation, wearing appropriate PPE, maintaining your equipment, and following all safety guidelines, you can create stunning wood designs while minimizing risks. Always remain vigilant and prepared to address any issues that arise during the cutting process.

Frequently Asked Questions

Can any type of wood be used for laser cutting?

While many types of wood can be used for laser cutting, some wood types perform better than others, depending on your project. As a rule of thumb, the drier and less resin the wood contains, the lighter the cutting edge.

However, some natural wood or wood material is unsuitable for laser cutting. For example, coniferous woods, such as fir, are not usually suitable for laser cutting.

What is the best file format for laser cutting wood?

The most popular type of file for laser cutting is a vector file. The best part about vector files is that they can be scaled to any size without losing quality. Consequently, raster files are also popular because they can be easily converted into vector files.

Should I sand wood before laser engraving?

Yes, sanding wood before laser engraving can help create a smoother surface, resulting in more precise and clean engraving. Use fine-grit sandpaper (200-300 grit) to prepare the surface.

The Takeaway: Use Wood for Laser Cutting Your Next Project

To recap, wood is an excellent material for laser cutting, but it’s essential to use the right kind of wood and prepare your wood and laser cutter for precise and accurate cuts.

Hopefully, this article has given you all the information you need to know about preparing laser-cut wood and more to ensure your next project is executed smoothly.