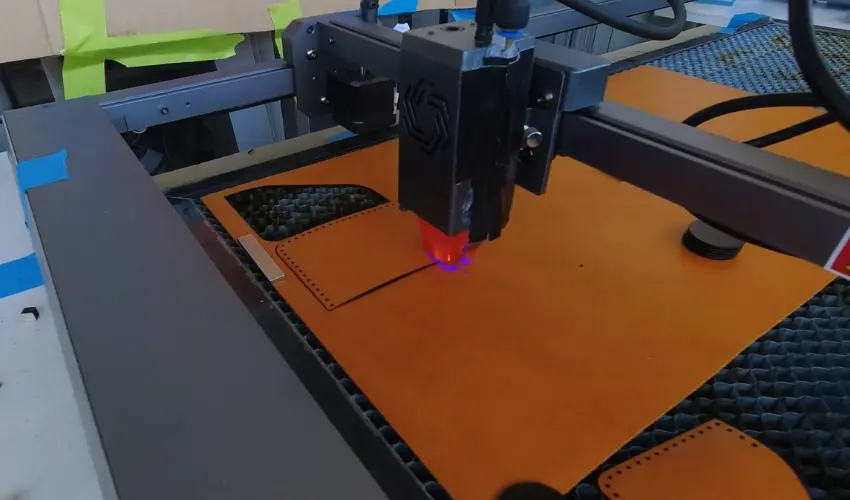

Diode lasers have become increasingly popular for their affordability, compact size, and ease of use. One common question among users, particularly those working with materials like leather, is can a 10W diode laser cut leather?

Yes, a 10W diode laser can cut leather. It is effective for cutting thin to medium thickness leathers (up to about 3.6 mm). However, for thicker leathers, the laser may require multiple passes and careful setting adjustments to achieve clean cuts.

In this article, we explore the capabilities of a 10W diode laser in cutting leather. We’ll discuss the types of leather it can handle, the thickness it can effectively cut, and provide tips for achieving the best results. Whether you’re a hobbyist or a professional leatherworker, this guide will help you understand if a 10W diode laser is suitable for your leather cutting needs.

Table of Contents

Understanding Whether a Diode Laser Can Cut Leather

Diode lasers emit light in the visible to near-infrared range and are typically less powerful than CO2 or fiber lasers. They are widely used for engraving and light-cutting applications on various materials, including wood, plastic, and some metals. Their power output ranges from a few milliwatts to several watts, with 10W being one of the most popular power options in the diode laser category.

Leather Cutting Capabilities of a 10W Diode Laser

1. Thin and Soft Leathers:

- Suitability: A 10W diode laser can cut through thin and soft leathers relatively easily. This includes leathers used for clothing, accessories, and light crafting materials.

- Thickness: Leathers up to 1-2 mm in thickness can typically be cut with a 10W diode laser, although this can vary depending on the specific type of leather and its properties.

2. Medium and Thick Leathers:

- Challenges: Cutting medium to thick leathers (greater than 2 mm) can be more challenging for a 10W diode laser. The laser may struggle to cut through thicker, denser leathers in a single pass, leading to the need for multiple passes or slower cutting speeds.

- Quality: Multiple passes can sometimes result in less clean edges and more burning or charring, affecting the overall quality of the cut.

3. Hard and Dense Leathers:

- Limitations: Very hard and dense leathers, such as those used for belts, saddlery, and heavy-duty applications, may be beyond the effective cutting capability of a 10W diode laser. The laser may not be able to penetrate these materials effectively, resulting in incomplete cuts and potential damage to the material.

Best Practices for Cutting Leather with a 10W Diode Laser

1. Material Preparation:

- Cleaning: Ensure the leather is clean and free of any coatings or residues that might interfere with the laser cutting process.

- Securing: Secure the leather firmly to the work surface to prevent any movement during cutting, which can affect precision.

2. Laser Settings:

- Power and Speed: Adjust the laser’s power and speed settings to find the optimal balance for cutting leather. Lower speeds with higher power settings can improve cutting efficiency but may increase the risk of burning.

- Focus: Ensure the laser is properly focused on the surface of the leather to maximize cutting efficiency and precision.

3. Multiple Passes:

- Technique: For thicker or denser leathers, using multiple passes at lower power settings can help achieve cleaner cuts with less burning. This approach allows the laser to gradually penetrate the material without excessive heat buildup.

- Cooling Periods: Allow short cooling periods between passes to prevent overheating and potential damage to the leather.

4. Ventilation and Extraction:

- Fume Extraction: Cutting leather produces fumes and odors that can be harmful if inhaled. Use proper ventilation and fume extraction systems to ensure a safe working environment.

- Air Assist: Utilize an air assist system to blow away debris and fumes from the cutting area, improving cut quality and reducing the risk of material burning.

Which 10W Diode Laser For Cutting Leather?

When it comes to cutting leather with precision and efficiency, the xTool D1 Pro 10W Diode Laser stands out as the top choice in its category. This laser cutter is renowned for its high performance, user-friendly design, and versatility, making it the best 10W diode laser for leather cutting. Here’s why the xTool D1 Pro 10W is the ultimate tool for leathercraft enthusiasts and professionals alike.

1. Superior Cutting Power

The xTool D1 Pro 10W Diode Laser delivers impressive cutting power for a 10W diode laser, making it highly effective for cutting through various types of leather, including thick and dense materials. Its advanced laser module ensures precise cuts, reducing the risk of burning or damaging the leather. This capability allows for intricate designs and clean edges, which are essential in leather crafting.

2. Precision and Accuracy

Precision is paramount when working with leather, and the xTool D1 Pro excels in this area. Its high-precision stepper motors and robust mechanical structure ensure that the laser head moves smoothly and accurately. This results in consistent and repeatable cuts, which are crucial for producing high-quality leather goods. Whether you’re creating detailed patterns or simple shapes, the xTool D1 Pro ensures that each cut is exact.

3. User-Friendly Software

The xTool D1 Pro comes with intuitive software that simplifies the design and cutting process. The software supports various file formats and offers a range of editing tools, making it easy to create and adjust designs before cutting. This user-friendly interface is perfect for both beginners and experienced users, allowing for a seamless transition from design to production.

4. Versatility

In addition to cutting leather, the xTool D1 Pro 10W Diode Laser is versatile enough to work with a variety of other materials, including wood, acrylic, and fabric. This makes it a valuable tool for any workshop, providing flexibility for different projects. Its ability to engrave as well as cut opens up even more possibilities for customization and creativity in leatherworking.

5. Safety Features

Safety is a critical consideration when working with laser cutters, and the xTool D1 Pro prioritizes this with several built-in safety features. These include protective covers, emergency stop buttons, and safety sensors that halt the laser if the machine is opened or moved unexpectedly. These features help protect the user from potential hazards, making the machine safer to operate.

6. Durability and Build Quality

The xTool D1 Pro is built to last, featuring a robust frame and high-quality components that ensure long-term durability and consistent performance. Its solid construction reduces vibrations and enhances stability, which is essential for achieving precise cuts over extended periods. This durability makes it a reliable investment for anyone serious about leather cutting.

7. Community and Support

Purchasing the xTool D1 Pro also means joining a community of users and gaining access to extensive support resources. xTool provides comprehensive customer support, tutorials, and a community forum where users can share tips, tricks, and project ideas. This support network can be incredibly helpful, especially for those new to laser cutting or looking to refine their skills.

What Thickness Leather Can The xTool D1 Pro 10W Diode Laser Cut?

The xTool D1 Pro 10W Diode Laser is a versatile and powerful tool, especially popular among leather crafters. However, when it comes to cutting leather, one of the most common questions is: What thickness of leather can the xTool D1 Pro 10W Diode Laser cut? In this section, we will explore the capabilities of this laser cutter, focusing on its performance with different leather thicknesses.

Understanding Leather Thickness

Leather is often measured in ounces, with one ounce roughly equating to 1/64th of an inch. For simplicity, leather thickness is also commonly referred to in millimeters:

- 2-3 oz leather: 0.8-1.2 mm

- 4-5 oz leather: 1.6-2.0 mm

- 6-7 oz leather: 2.4-2.8 mm

- 8-9 oz leather: 3.2-3.6 mm

Understanding these measurements is crucial for determining what thicknesses the xTool D1 Pro 10W can effectively handle.

Performance of the xTool D1 Pro 10W with Leather

1. Thin Leather (0.8-2.0 mm):

The xTool D1 Pro 10W Diode Laser excels at cutting thin leather, such as 2-5 oz (0.8-2.0 mm). It can produce clean and precise cuts with minimal effort. This thickness range is ideal for detailed projects like wallets, bookmarks, and other fine leather goods.

- Speed and Power Settings: Lower power settings and moderate speeds are recommended to avoid burning or charring the edges.

- Cut Quality: Expect smooth, clean edges with minimal post-processing required.

2. Medium Leather (2.4-3.6 mm):

For medium-thickness leather, such as 6-9 oz (2.4-3.6 mm), the xTool D1 Pro 10W still performs well, though adjustments to speed and power are necessary to achieve optimal results. This range is suitable for products like belts, bags, and straps.

- Speed and Power Settings: Higher power settings and slower speeds will be needed to ensure a complete cut through the material.

- Cut Quality: The cut quality remains good, but it may require some fine-tuning of settings to avoid excessive scorching.

3. Thick Leather (4.0+ mm):

When dealing with thick leather (above 4.0 mm), the xTool D1 Pro 10W starts to reach its limits. While it can cut through thicker leather, the process requires multiple passes and careful adjustments to the settings.

- Speed and Power Settings: Maximum power settings and very slow speeds, along with multiple passes, will be necessary.

- Cut Quality: Cutting thick leather might result in more pronounced charring, and additional post-processing may be required to clean up the edges.

We recommend the xTool D1 Pro 20W Version for leather cutting above 2.4mm. A detailed review of the 20W version can be found here

Tips for Cutting Leather with the xTool D1 Pro 10W

1. Test Cuts:

Always perform test cuts on a scrap piece of leather before starting your main project. This helps dial in the correct settings for your specific leather thickness and type.

2. Ventilation:

Ensure proper ventilation while cutting leather, as the process can produce fumes. An exhaust system or fume extractor is recommended for safety and to maintain a clean working environment.

3. Focus Adjustment:

Proper focus is crucial for achieving clean cuts. Make sure the laser is correctly focused on the surface of the leather to maximize cutting efficiency.

4. Multiple Passes:

For thicker leather, using multiple passes at lower power settings can reduce charring and improve cut quality. This technique allows for gradual cutting without overwhelming the material.

5. Maintenance:

Regularly clean the laser cutter to ensure optimal performance. Accumulated debris can affect the laser’s efficiency and cutting ability.

What Is The Best Laser For Cutting leather?

The best laser for cutting leather largely depends on your specific needs. For hobbyists and small businesses, the xTool D1 Pro 10W or 20W Diode Laser offers a great balance of affordability and performance.

For more professional or industrial applications, the OMTech 50W CO2 Laser Engraver provides higher power and versatility, making it ideal for thicker leather and larger projects. The xTool P2 55W CO2 Laser is a great choice for those needing high precision and reliability. Consider your budget, project scale, and required precision when choosing the best laser cutter for your leatherworking needs.

Detailed Reviews of the OMTech 50W CO2 Laser and the xTool P2 55W CO2 Laser Can Be Found in this article I wrote Here

Conclusion

A 10W diode laser can effectively cut thin and soft leathers, making it suitable for light crafting, fashion accessories, and small-scale leather projects. However, its capability to cut medium to thick or very dense leathers is limited, often requiring multiple passes and careful adjustments to settings.

By following best practices for material preparation, laser settings, and ventilation, you can achieve satisfactory results with a 10W diode laser for your leather cutting needs. For more demanding leather cutting tasks, particularly with thicker and denser materials, a higher-powered laser, such as a CO2 laser, may be a more suitable and efficient option.